Dust sweeping device for filter element of dust collector

A dust collector and ash sweeping technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc. The effect of high work efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

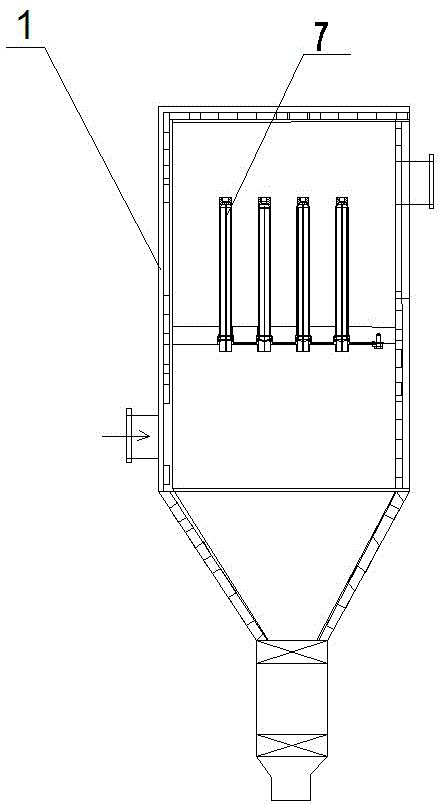

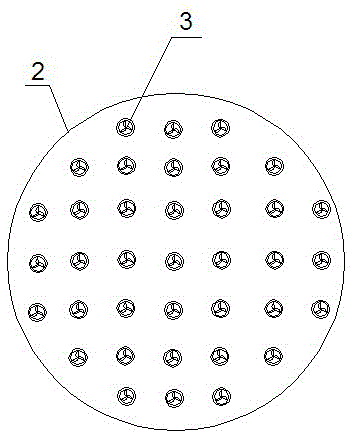

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a dust-sweeping device for a filter element of a dust collector includes a rotating bracket and a rotating dust-sweeping mechanism.

[0025] The rotating bracket is divided into upper and lower parts, the lower part of the rotating bracket is arranged at the opening of the filter element 7 of the dust collector, and the upper part of the rotating bracket is arranged at the top of the filter element 7 of the dust collector.

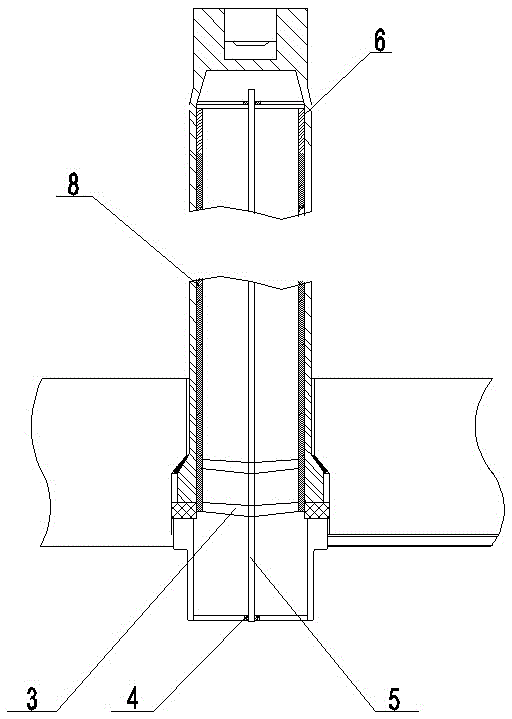

[0026] The rotating ash sweeping mechanism includes fan blades 3, a main shaft 5 and a dust sweeping mechanism, the main shaft 5 runs through the fan blades 3 and the ash sweeping mechanism, and the main shaft 5 is connected with a rotating bracket.

[0027] The dust sweeping mechanism includes a rectangular frame 6 and bristles 8 , and the bristles 8 are arranged outside the rectangular frame 6 .

[0028] The main shaft 5 is connected with the rotating bracket through the bearing...

specific Embodiment 2

[0030] The difference from the first embodiment is that the number of the fan blades 3 is two or three.

[0031] Working principle and structure of the present invention are described in conjunction with embodiment and technical scheme:

[0032]In the present invention, the gas that needs to be filtered enters the cavity through the air inlet hole at the lower part of the dust collector 1, and is continuously discharged to the upper outlet under the drive of the air flow. A partition is set in the middle of the dust collector to play a sealing role to isolate static air. and unfiltered gas, set the dust collector filter element on the partition to filter the gas; after long-term use, the surface of the dust collector filter element in contact with the unfiltered gas has accumulated a large amount of dust, which seriously affects the filtration efficiency and needs to be dealt with in time , so as to ensure the normal passage of gas; the present invention is designed according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com