Electrostatic dust removing robot

A technology of electrostatic dust removal and robotics, applied in electrostatic separation, electrostatic effect separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

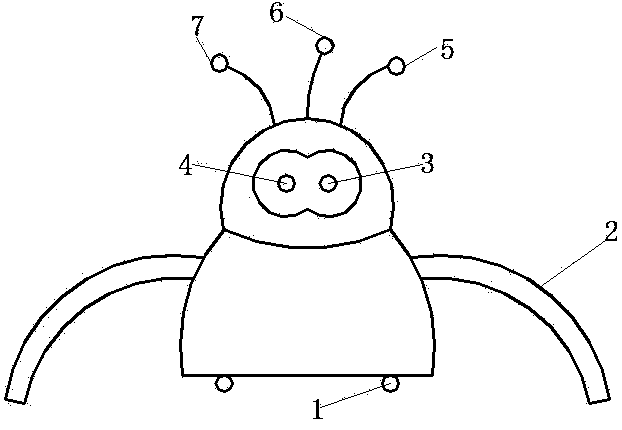

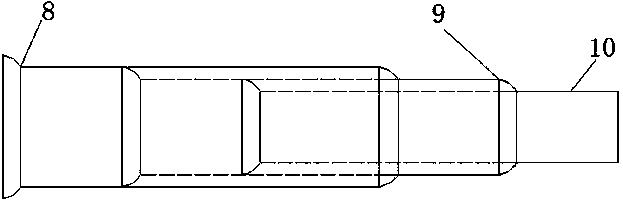

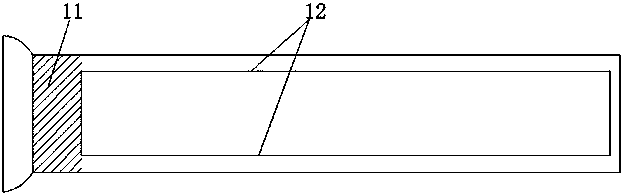

[0031] Such as Figure 1 to Figure 4 As shown, an electrostatic dust removal robot includes a body, a mobile system, a dust removal arm 2, and the like.

[0032] There are dust removal arms on both sides of the upper part of the fuselage. The upper part of the body is the head of the robot. The power switch 3 and the dust removal switch 4 are installed on the eye area of the head. The power indicator light 5 and the dust removal indicator light 6 are respectively installed on the head. , Malfunction indicator light 7.

[0033] There are wheels 1 at the bottom of the fuselage, which are equivalent to the wheels of a bicycle, to facilitate the walking of the robot; and the two switches are designed on the eyes of the robot, and the power switch 3 and the dust removal switch 4 are separated to prevent the robot from starting Vacuuming causes waste of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com