Prepreg/resin transfer molding co-curing process method for composite materials

A technology of resin transfer molding and composite material, applied in the field of composite material molding, can solve the problems of low molding quality and performance, low manufacturing cost, etc., and achieve the effect of high degree of freedom in mold design, reduced manufacturing cost, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

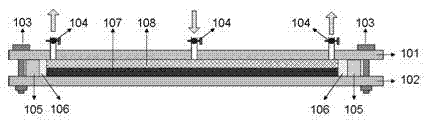

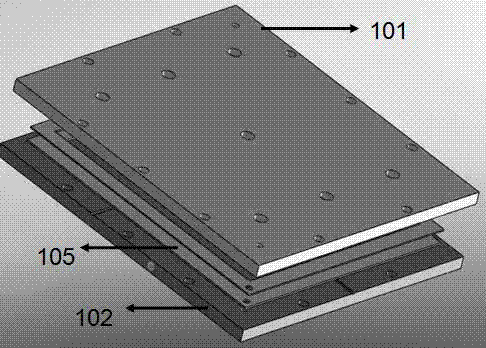

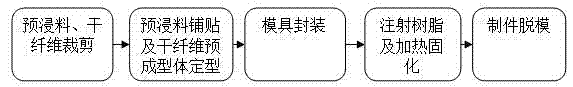

Embodiment 1

[0040] Composite parts were prepared by prepreg / resin transfer molding co-curing process. The dry fiber is T700 unidirectional carbon fiber cloth, the injection resin is epoxy resin, and the prepreg is T300 carbon fiber / epoxy prepreg. The layup method of prepreg and dry fiber cloth is unidirectional layup[0] 16 . A prepreg blank is placed below the dry fiber preform. The injection pressure during the molding process is 0.2MPa. After the injection is completed, close the glue outlet and the glue inlet, and raise the temperature at 1-2°C / min to 180°C and keep it for 2 hours to complete the curing.

Embodiment 2

[0042] Composite parts were prepared by prepreg / resin transfer molding co-curing process. The dry fiber is unidirectional glass fiber cloth, the injection resin is phenolic resin, and the prepreg is glass fiber / phenolic resin prepreg. The layering method of prepreg is [45 / 0 / -45 / 90 / 45 / 0 / -45 / 0 / 45 / -45], and the layering method of dry fiber cloth is [-45 / 0 / 45 / 90 / -45 / 0 / 0 / 45 / 90 / -45 / 0 / 45]s. A prepreg blank is placed below the dry fiber preform. The injection pressure during the molding process is 0.1MPa. After the injection is completed, close the glue outlet and the glue inlet, and raise the temperature at 1-2°C / min to 180°C and keep it for 3 hours to complete the curing.

Embodiment 3

[0044] Composite parts were prepared by prepreg / resin transfer molding co-curing process. The dry fiber is T800 carbon fiber plain cloth, the injection resin is Shuangma resin, and the prepreg is T800 carbon fiber / Shuangma resin prepreg. The layering method of prepreg is [45 / 0 / -45 / 90 / 0 / 45 / 0 / -45 / 90 / 0 / 45 / 0 / -45 / 0 / 45 / -45], dry fiber cloth The layering method is [-45 / 0 / 45 / 90 / -45 / 0 / 45 / 90 / -45 / 0 / 45 / 90 / -45 / 0 / 45]. A prepreg blank is placed below the dry fiber preform. The injection pressure during the molding process is 0.3MPa. After the injection is completed, close the glue outlet and the glue inlet, and raise the temperature at 1-2°C / min to 210°C and keep it for 5 hours to complete the curing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com