Degassing rod for aluminum alloy wheel hub cast liquid aluminum

An aluminum alloy wheel hub and casting aluminum technology, which is applied in the field of aluminum alloy wheel casting liquid aluminum degassing rods, can solve the problems affecting the production qualification rate of wheel hubs and the mechanical properties of castings, aluminum alloy wheel hub casting needles, obvious slag holes, and the design of degassing rods. Imperfect and other problems, to achieve the effect of simple and reasonable structure, improved mechanical properties, and increased unit volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

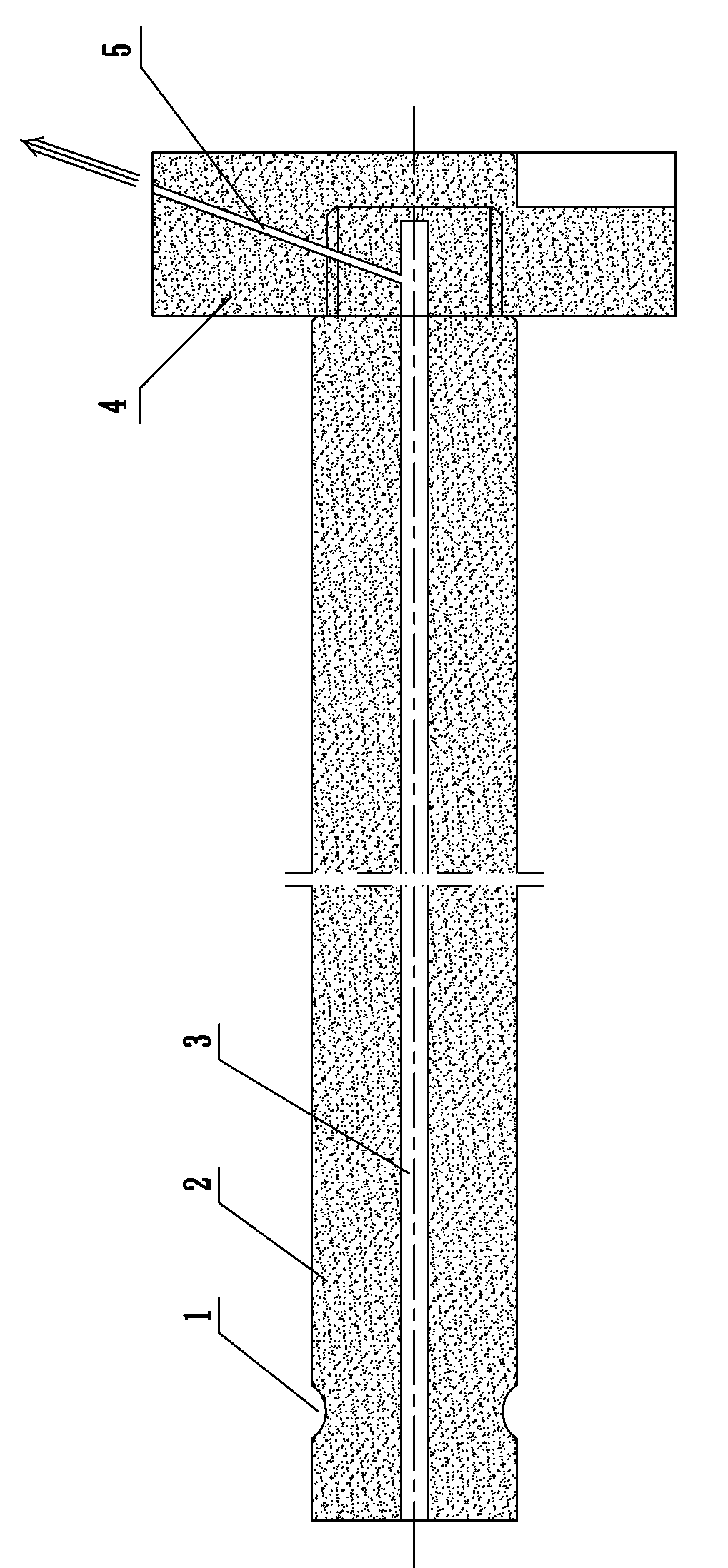

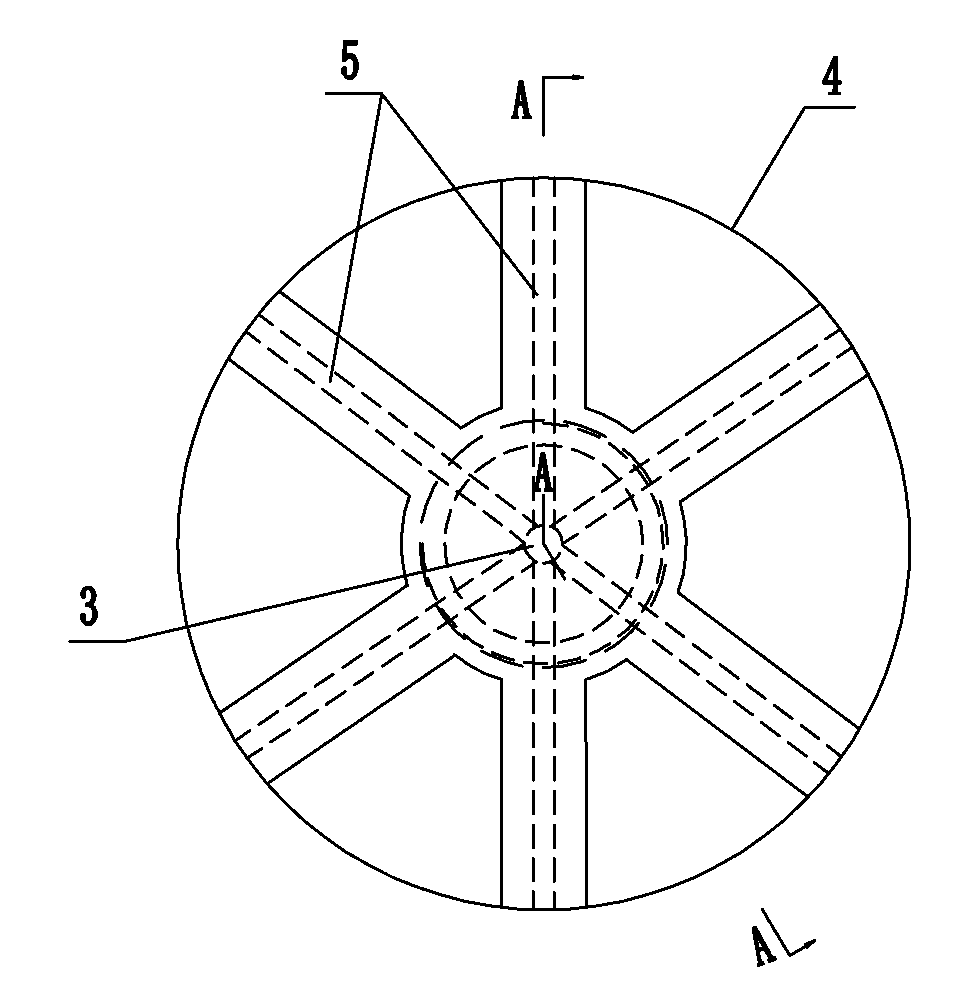

[0012] see figure 1 , 2 , the present invention has a graphite rod 2, a central air channel 3 is opened on the graphite rod 2, and a graphite rotor 4 is installed at one end of the graphite rod 2, especially: six radially arranged exhaust holes are arranged on the graphite rotor 4 5. The exhaust holes 5 are arranged obliquely to the end surface, and the inner ends of the exhaust holes 5 are all communicated with the central air channel 3 .

[0013] In this embodiment, the exhaust hole 5 opened on the graphite rotor 4 has a diameter of 3mm, and the inclination angle with the end surface is 20°-25°, specifically 20°.

[0014] In this embodiment, a groove 1 is formed on the other end of the graphite rod 2 opposite to the graphite rotor 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com