Rotor core components, motors, air conditioners

A rotor iron core and component technology, which is applied in the fields of rotor iron core components, air conditioners, and motors, can solve the problems of reducing the length of the magnetic steel, increasing the magnetic flux leakage, occupying the radial space of the magnetic steel groove, etc., so as to increase the radial length, Increase the flux linkage output and reduce the effect of flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

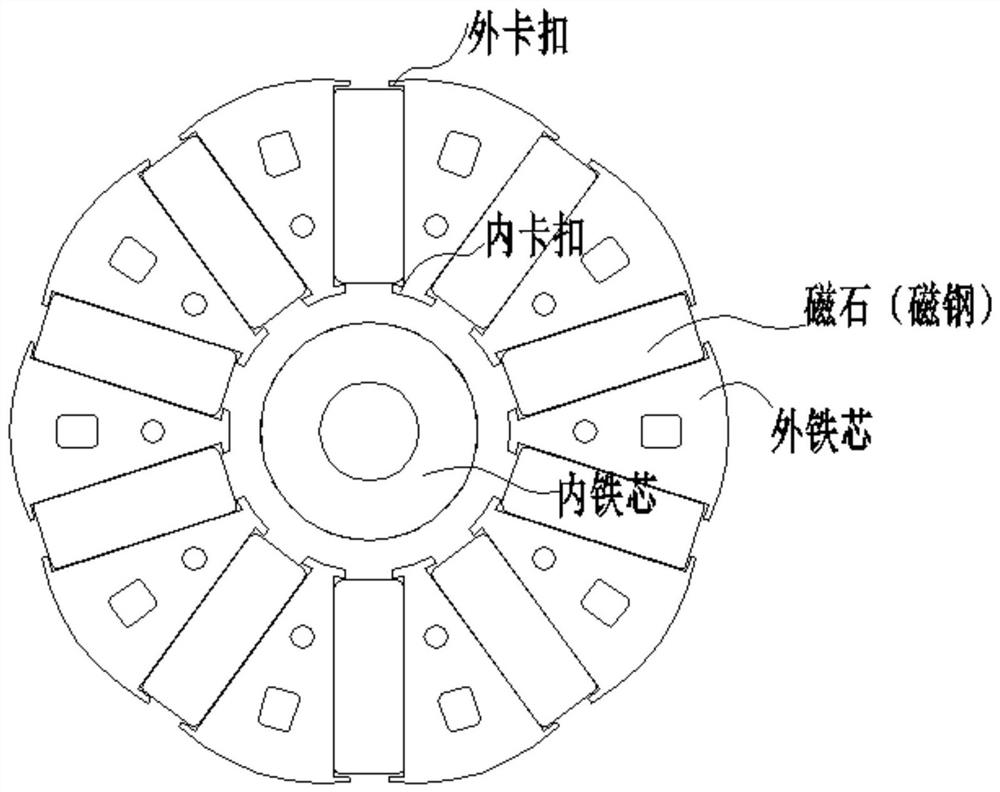

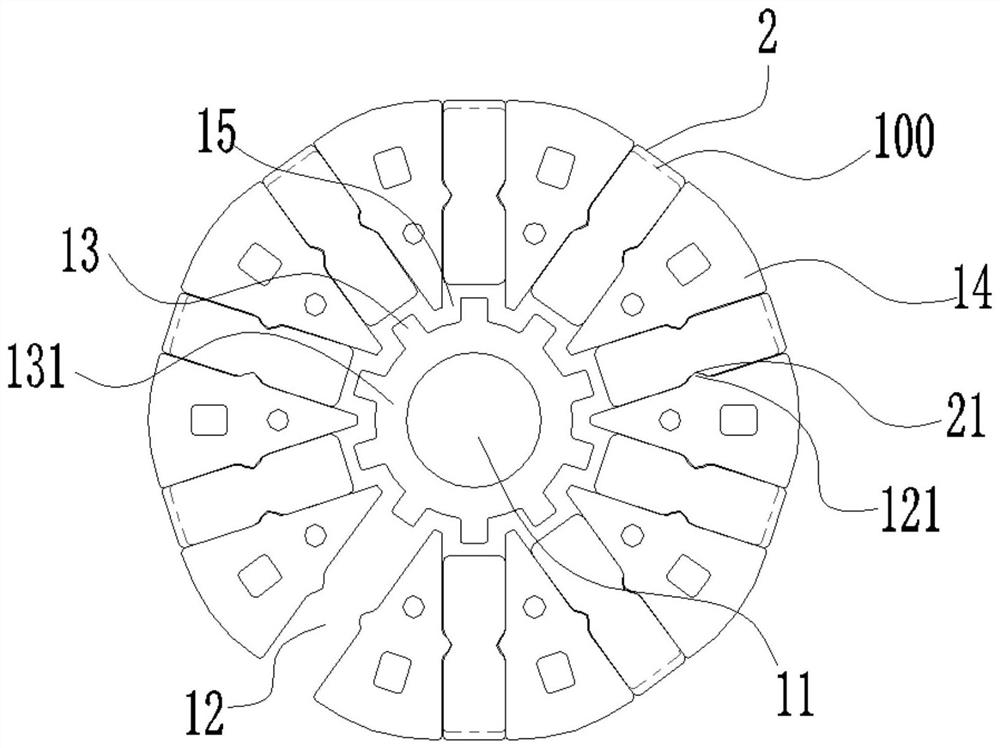

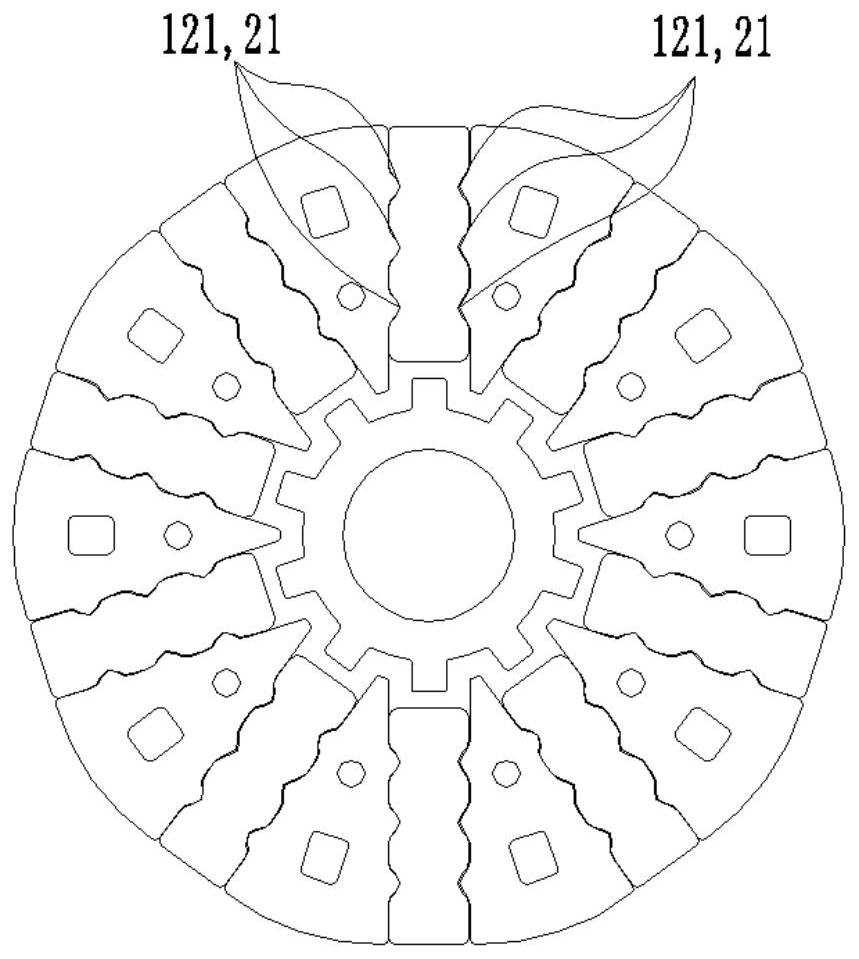

[0024] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present invention, a rotor core assembly is provided, including a rotor core 1 and a plurality of magnetic steels 2, the rotor core 1 has a shaft hole 11 and is evenly spaced around the shaft hole 11 A plurality of magnetic steel grooves 12, the magnetic steel grooves 12 extend along the radial direction of the shaft hole 11 and penetrate the outer peripheral wall of the rotor core 1, and a plurality of the magnetic steel grooves 2 are installed in one-to-one correspondence In the plurality of magnetic steel slots 12 , there is a concave-convex limiting structure between the radial side walls of the magnetic steel slots 12 and the corresponding mating surfaces of the magnetic steel 2 . In this technical solution, the radial positioning of the magnetic steel 2 no longer adopts the buckle structure at the notch of the magnetic steel groove 12 in the prior art, but on the radial side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com