Growth method for controlling diameter of rod-like sapphire crystal based on protective atmosphere

A sapphire crystal, protective atmosphere technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., to achieve the effect of ensuring compactness, high cost performance, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

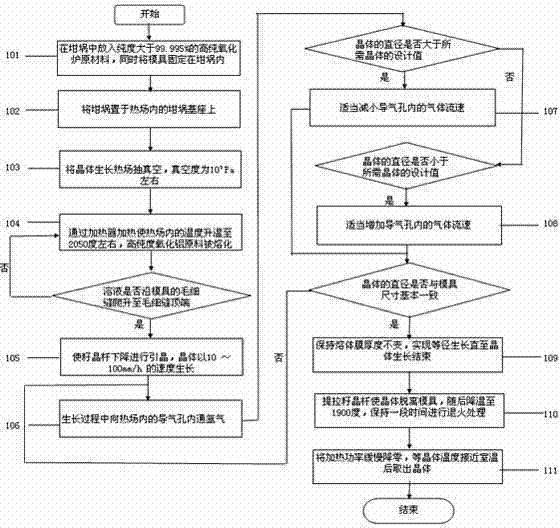

Method used

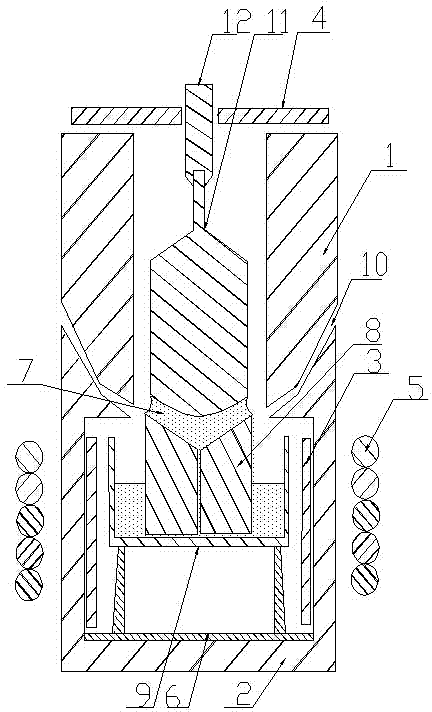

Image

Examples

Embodiment 1

[0057] Embodiment 1: When the diameter of the sapphire crystal is 47MM, it is necessary to increase the gas flow rate to increase its diameter to 50MM, the data are shown in the table below:

[0058] Current crystal diameter (MM) Gas flow rateL / S Ventilation time (S) Gas diameter after ventilation (MM) 47 1 30 50 47 5 10 50 47 10 - The height of the liquid film decreases, h≤0, at this time the liquid film freezes

[0059] The above data show that when it is necessary to increase the diameter of the sapphire crystal, it is better to control the gas flow rate between 5-8S.

Embodiment 2

[0060] Embodiment 2: When the diameter of the sapphire crystal is 54MM, it is necessary to reduce the gas flow rate to reduce its diameter to 50MM, the data are shown in the table below

[0061] Current crystal diameter (MM) Raw gas flow rate L / S Existing gas flow rate L / S Ventilation time (MIN) Gas diameter after ventilation (MM) 54 5 2 120 50 54 5 1 60 50 54 5 0 37 50

[0062] The above data show that when the sapphire crystal diameter needs to be reduced, its aeration time is longer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com