A vehicle-mounted vibration-damping camera mount

A camera frame and camera technology, applied in the field of camera frames, can solve problems such as blurred photos, camera failures, and camera frames that cannot buffer shocks, etc., and achieve the effects of small size, convenient production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

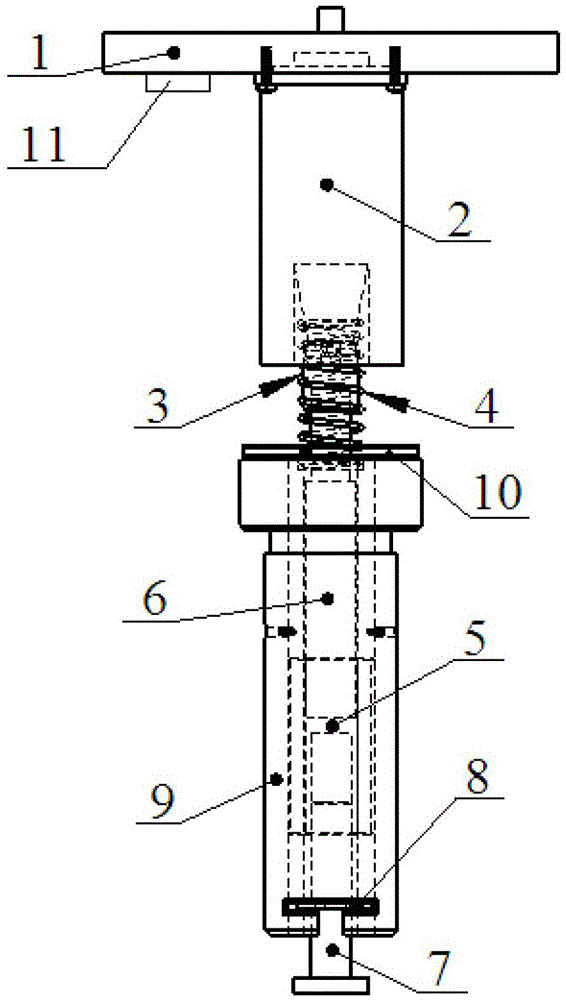

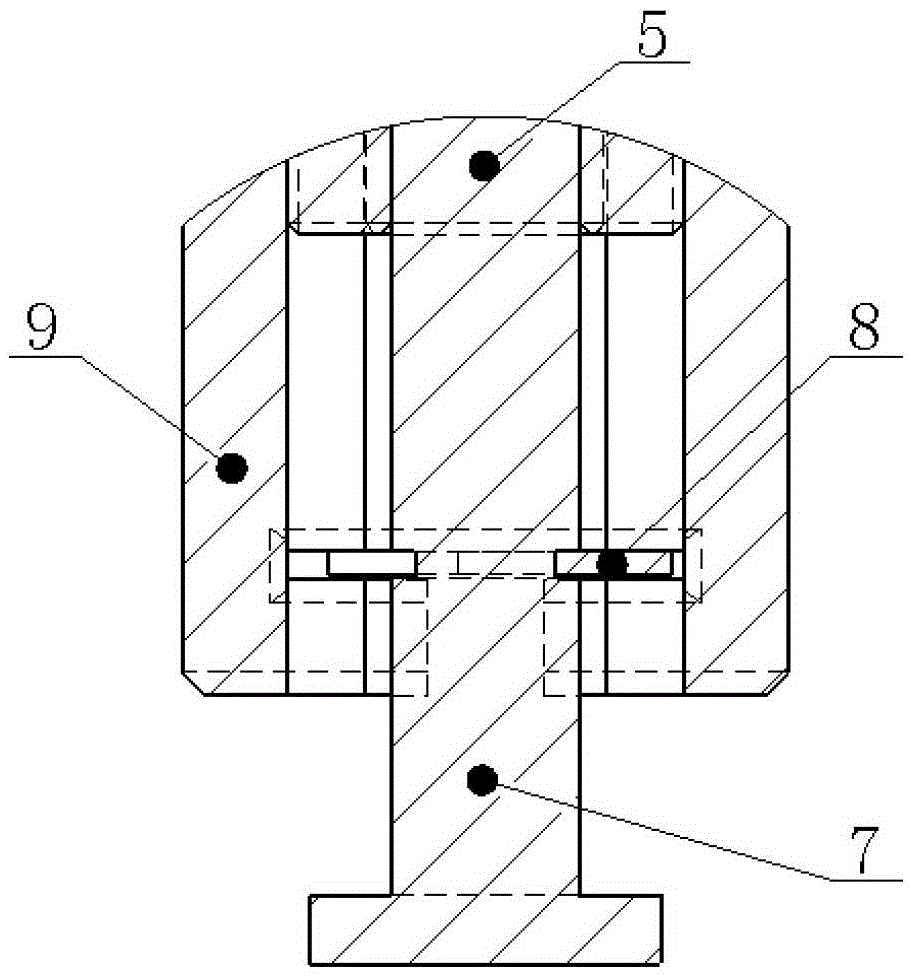

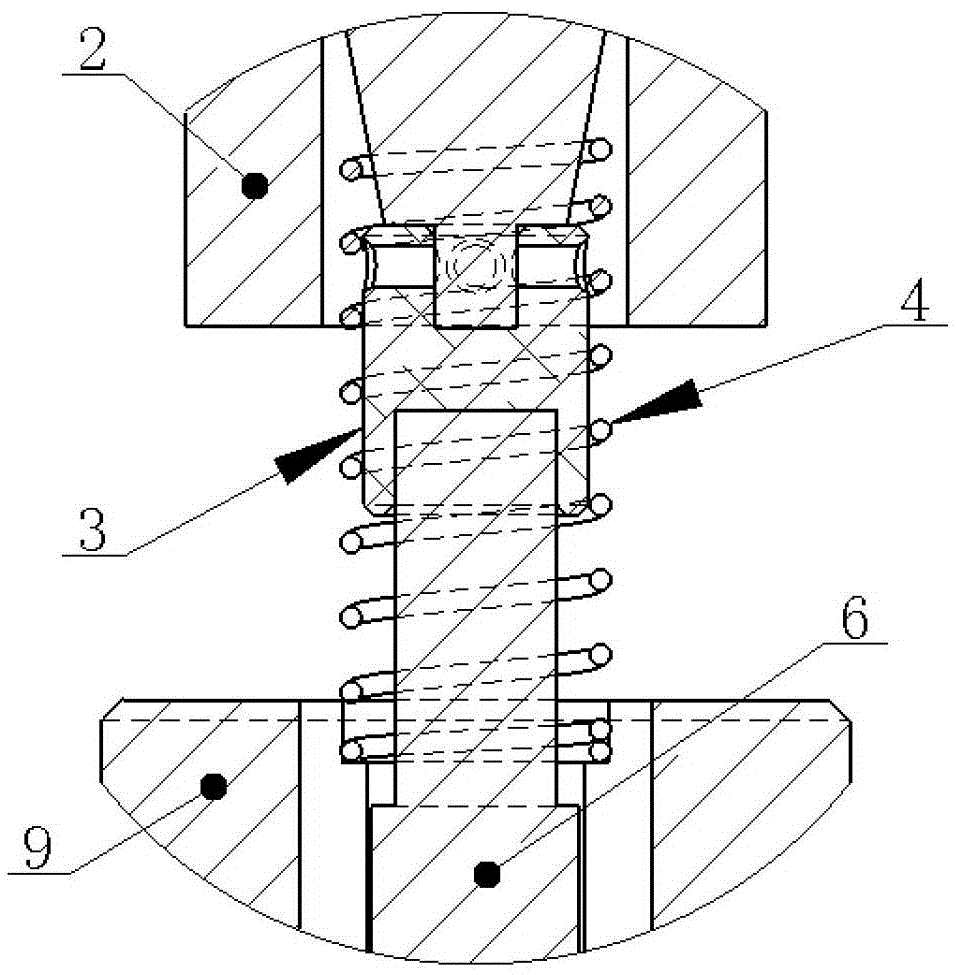

[0031] A vehicle-mounted vibration reduction camera mount, such as Figure 1 to Figure 4 As shown, the camera frame includes a camera platform 1, a sensing and control center 11, an electromagnet 2, a damper 6, a lower base 9, a spring 4 and a permanent magnet 10, wherein the electromagnet 2 is connected to the lower end of the camera platform 1 , the lower end of the damper 6 is sleeved inside the lower base 9, the upper end of the damper 6 is connected to the electromagnet 2 through the connector 3, the spring 4 is sleeved outside the upper end of the damper 6, and the upper and lower ends of the spring 4 are connected to the electromagnet 2 and the lower end respectively. The base 9 abuts, the sensing and control center 11 is arranged on the lower side of the camera platform 1 and connected with the electromagnet 2 , and the permanent magnet 10 is arranged on the top of the lower base 9 . The sensing and control center 11 includes an acceleration sensor, a single-chip micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com