A honeycomb panel fatigue testing device and testing method

A technology of fatigue testing and honeycomb panels, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problem of hindering the development of the aerospace industry of new structural honeycomb panels, the inability to accurately measure the actual performance, and the clamping In order to reduce manpower consumption and test costs, facilitate judgment and recording, and achieve uniform force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

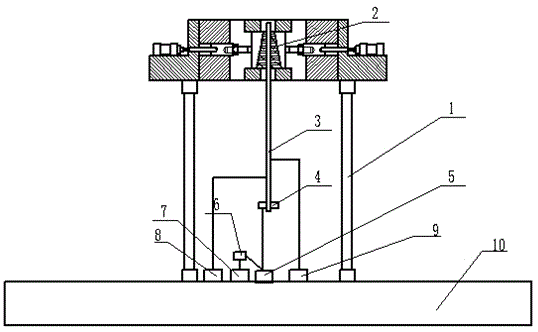

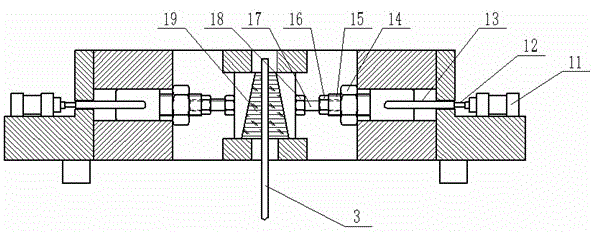

[0020] Such as Figures 1 to 2 As shown, the honeycomb panel fatigue test device includes a vertical test bracket 1, a pneumatic start nut locking trapezoidal section fixture 2, an eccentric wheel vibrator 4, an eccentric wheel 5, a frequency converter 6, a motor 7, and a capacitive strain gauge 8 , the eddy current precision displacement sensor 9 and the lower base 10 of the fatigue testing machine. The trapezoidal cross-section clamp 2 vertically clamps the clamped sample 3, and the bottom of the clamped sample 3 is provided with an eccentric wheel vibrator 4, and the eccentric wheel vibrator 4 is sequentially connected to the eccentric wheel 5, an external frequency converter 6, and an external frequency converter 6 The opening is controlled by the motor 7 to achieve the purpose of frequency control, and the lower part of the clamped sample 3 is connected with the capacitance strain gauge 8 and the eddy current precision displacement sensor 9 respectively.

[0021] Among t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com