Acceleration and deceleration planning method and device for numerical control system and numerical control machine tool

A technology of numerical control machine tools and numerical control systems, which is applied in the field of numerical control machine tools, can solve problems such as excessive speed and distance, calculation errors of speed and distance, etc., and achieve the effect of improving speed planning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

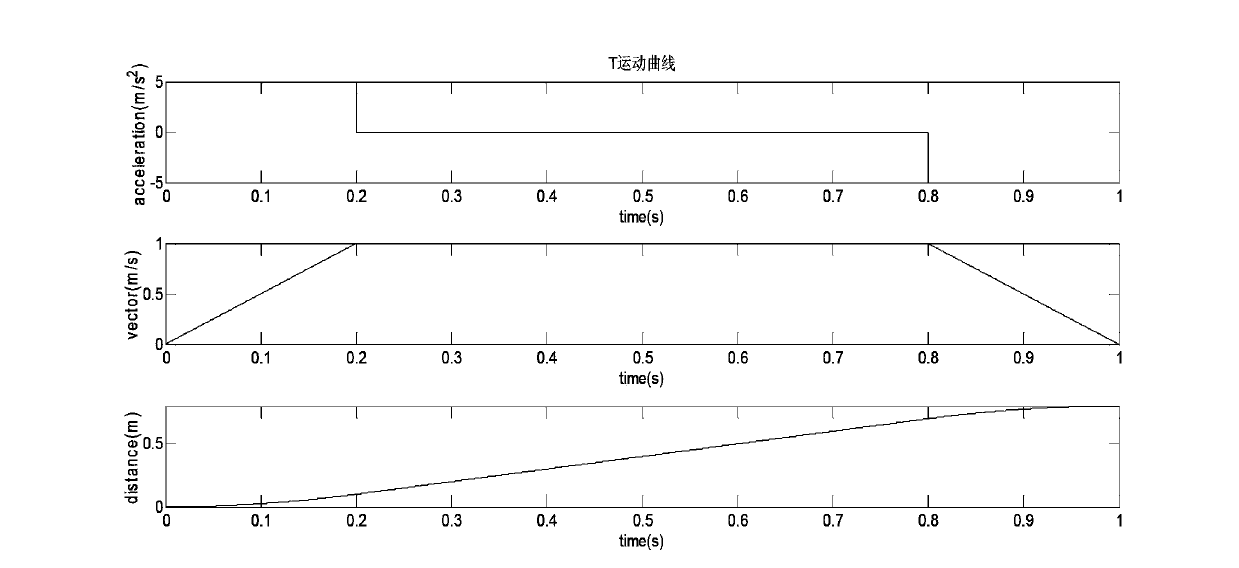

[0057] Embodiment 1, please refer to image 3 , an acceleration and deceleration planning method for a numerical control system provided by an embodiment of the present invention includes:

[0058] Step S301, performing T-curve speed planning on the machining trajectory of the CNC machine tool operating equipment, and obtaining the time of uniform acceleration, constant speed and uniform deceleration in the T-curve. The CNC machine tool operating equipment is the hardware execution unit in the CNC system, including CNC cutting head, CNC laser welding head, CNC operating platform, robot arm and other components that can be controlled by software programs. This step includes: determining the time of uniform acceleration and the track length of uniform acceleration in the T-shaped curve according to the preset target speed, initial velocity and maximum acceleration of the CNC machine tool operating equipment; then according to the preset target speed and end point of the CNC mach...

Embodiment 2

[0082] Such as Figure 4 As shown, an acceleration and deceleration planning device 100 for a numerical control system provided by an embodiment of the present invention includes:

[0083] The speed planning module 10 is used to perform T-curve speed planning on the machining trajectory of the CNC machine tool operating equipment, and obtain the time of uniform acceleration, constant speed and uniform deceleration in the T-curve. The speed planning module 10 also includes: a track length acquisition unit of uniform acceleration, which is used to determine the time of uniform acceleration and the track length of uniform acceleration in the T-shaped curve according to the preset target speed, initial velocity and maximum acceleration of the CNC machine tool operating equipment; The trajectory length acquisition unit for deceleration determines the time of uniform deceleration and the trajectory length of uniform deceleration in the T-shaped curve according to the preset target s...

Embodiment 3

[0088] Such as Figure 5 As shown, the present invention provides a numerically controlled machine tool 200, comprising a control device 201, a drive device 202 and a power supply device 203, the power supply device 203 supplies power to the numerically controlled machine tool 200, and the control device 201 controls the drive device 202 to drive the operating equipment of the numerically controlled machine tool 200 For operation, the CNC machine tool 200 also includes an acceleration and deceleration planning device 100, and the acceleration and deceleration planning device 100 includes: a speed planning module 10, which is used to perform T-curve speed planning on the machining trajectory of the CNC machine tool operating equipment, and obtain the T-curve. The time of acceleration, uniform speed and uniform deceleration; the rounding compensation module 20 is used to separately adjust the three time periods of uniform acceleration, uniform speed and uniform deceleration in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com