Root crop harvesting machine

A technology for crops and rhizomes, which is applied in the field of rhizome crop harvesters, can solve problems such as difficulty in harvesting, and achieve the effects of simple operation, improved efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

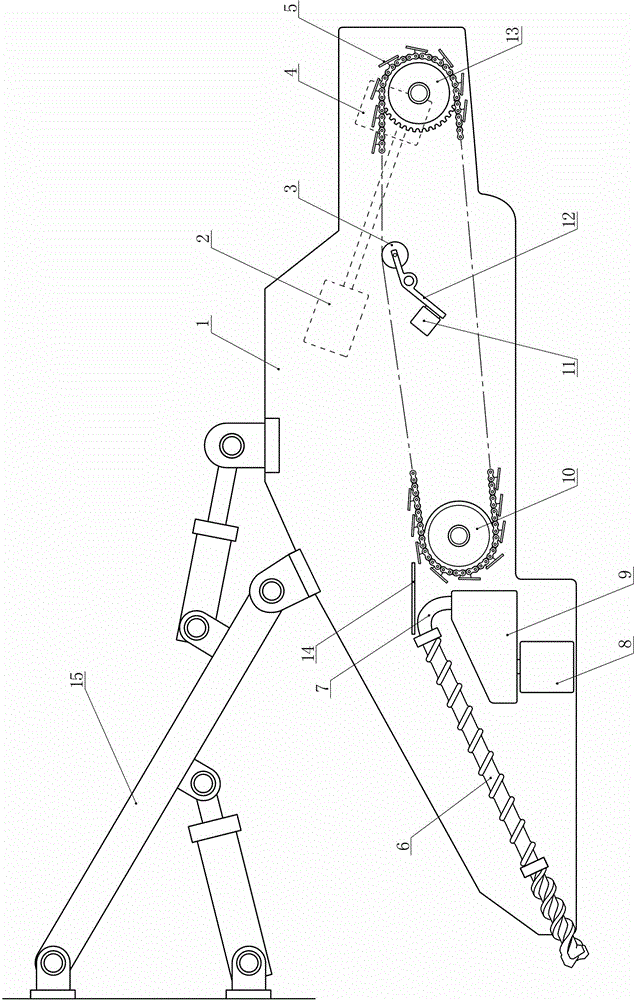

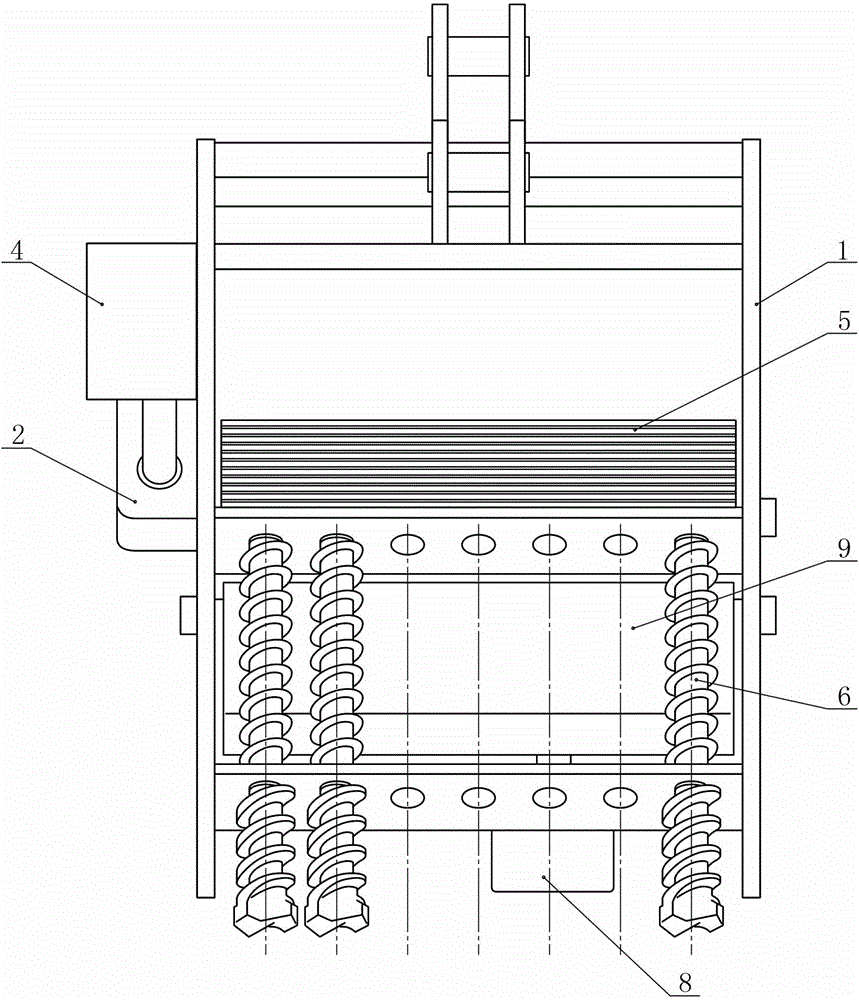

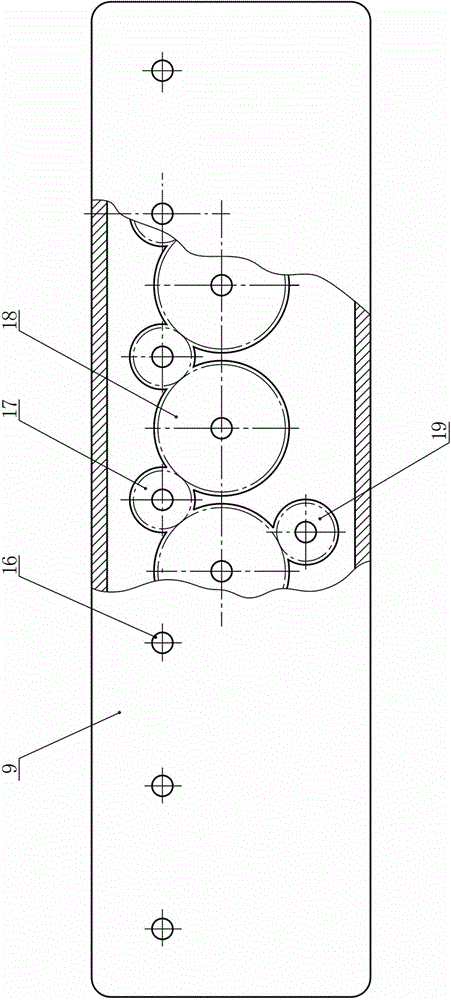

[0024] From Figure 1 ~ Figure 3 As can be seen, the technical scheme of the present invention is: comprise soil loosening mechanism power unit 8, multi-head output gearbox 9, transmission mechanism power unit 2, speed reducer 4, boom 15; device, a row of power output shafts and a row of intermediate gear shafts are housed in the box, and the power output shafts and the intermediate gear shafts are arranged at intervals in the shape of a character; the driven gear 17 and the intermediate gear 18 are respectively fixed on the power output shaft and the intermediate gear shaft, Adjacent driven gears 17 and intermediary gears 18 mesh with each other, and through intermediary gears 18, the power output shafts rotate in the same direction; the gearbox in this embodiment is equipped with seven power output shafts in parallel. The soil loosening power mechanism device of the present embodiment adopts a hydraulic motor, and the power output shaft of the hydraulic motor is connected wi...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 is that the surface of the drill rod 6 is smooth and has no helical raised lines; Bevel gear 21; the end (high end) of each drill rod 6 of the soil loosening mechanism meshes with the bevel gear 21 at the end of the multi-head output gearbox 9 power output shaft through the bevel gear;

[0038]The conveyor belt of this embodiment is equipped with a tensioning device, the tensioning device is a tensioning wheel 20 with adjustable wheel position, which is used to compensate for the chain slack caused by wear; the tensioning wheel 20 is located between the driving wheel 13 and the driven wheel 10 , the driving wheel shaft, the driven wheel shaft, and the tensioning wheel shaft are distributed in the shape of a character, and the tensioning wheel 20 is against the lower half of the conveyor belt; the two ends of the wheel shaft of the tensioning wheel are connected to the frame with an adjustment mechanism, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com