High-rigidity short stress path rolling mill

A technology with short stress line and high rigidity, which is applied in the field of high rigidity short stress line rolling mill, which can solve the problems of poor frame rigidity, increased workload, poor interchangeability, etc., and achieve the effect of large sliding contact surface and enhanced versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

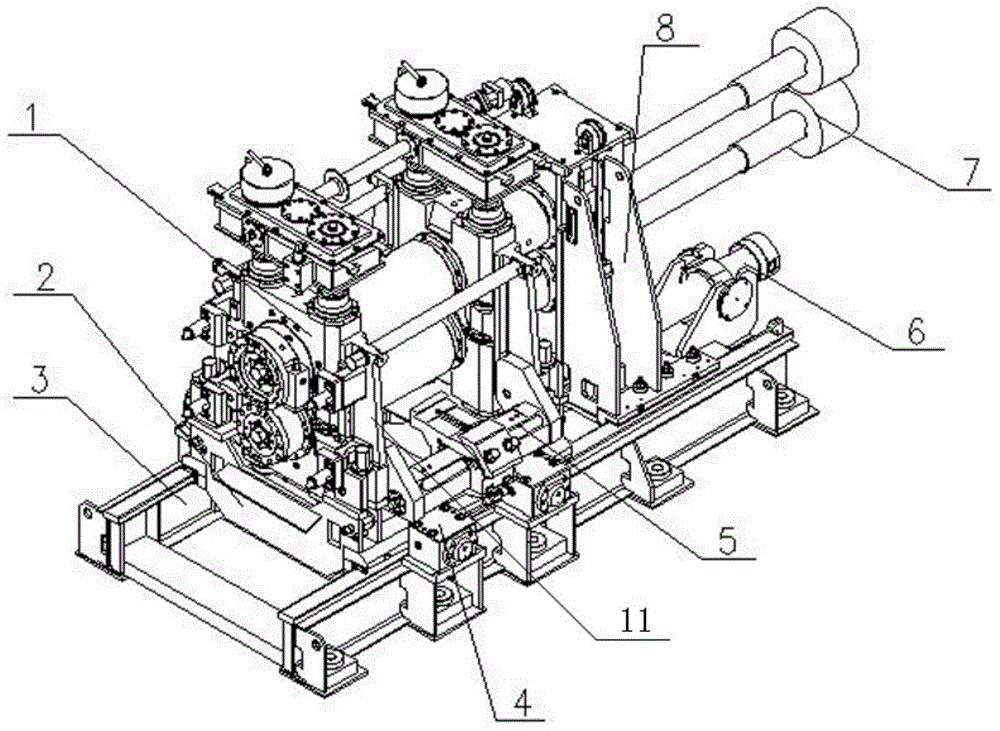

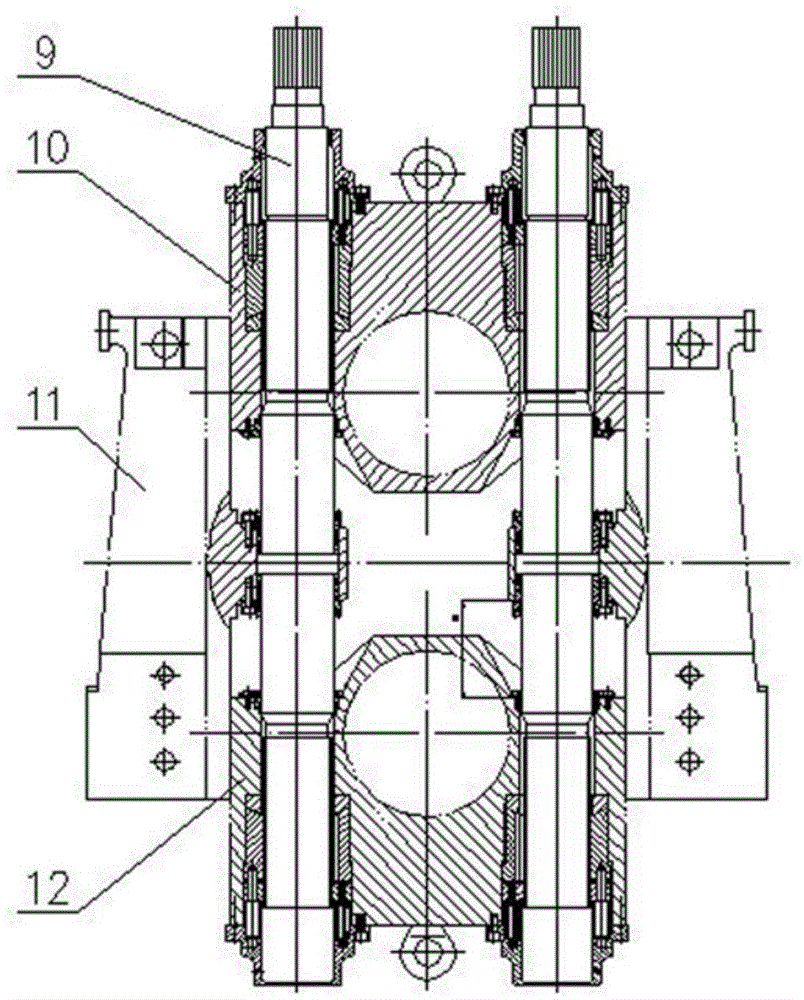

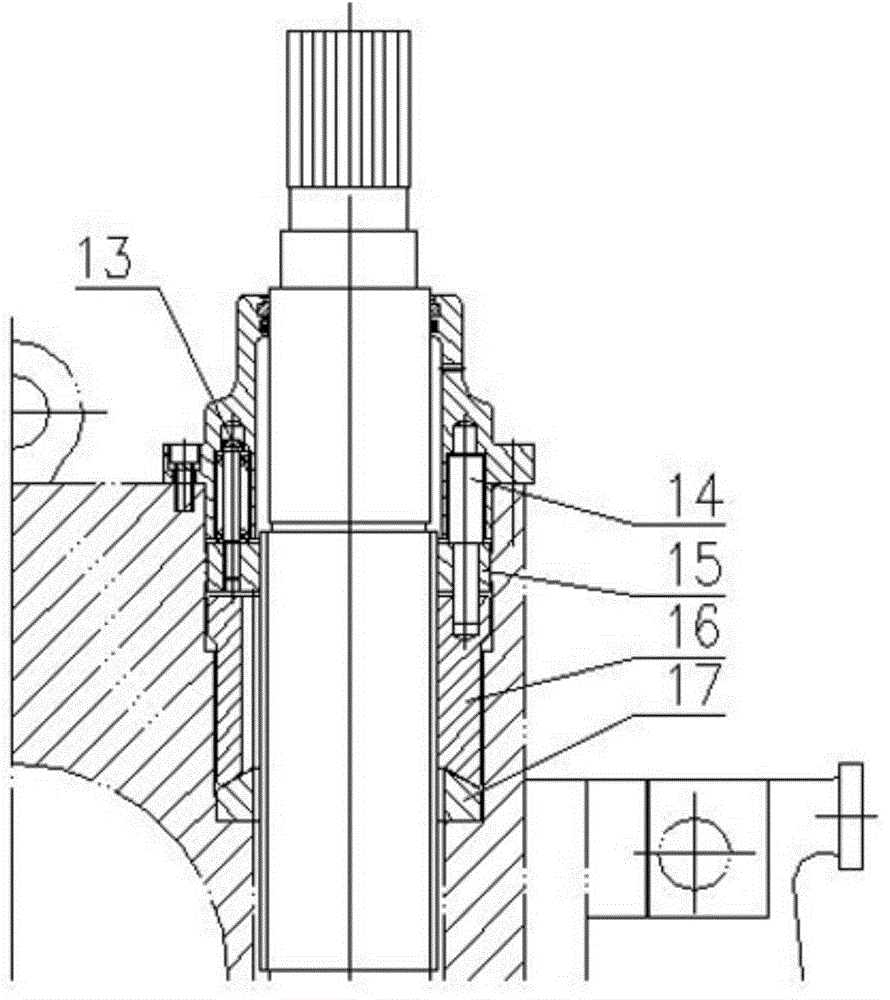

[0020] Such as figure 1 As shown, a high-rigidity short stress line rolling mill, working core 1, movable base 2, fixed base 3, locking device 4, guide beam 5, traverse device 6, cardan shaft 7, shaft bracket 8 As well as the transmission assembly, the working core is connected to the movable base through four joint bolts, the movable base is connected with the connecting shaft bracket through the hydraulic cylinder, and the rolling mill traverse device is connected with the connecting shaft bracket through the pin shaft. Driven by the moving device, the rolling mill core, movable base, connecting shaft bracket and universal joint shaft all slide on the fixed base, thereby realizing the replacement of the working roll groove of the rolling mill. When the rolling mill is put into operation, the lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com