Preparation method of antimony-free high-environmental protection flame retardant mixture and antimony-free high-environmental protection flame retardant mixture

A flame retardant and mixture technology, applied in the field of flame retardant manufacturing, can solve the problems of easy flame retardant, high flame retardant smoke production, respiratory system hazards, etc., to enhance binding force, improve synergistic effect, and improve uniform dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

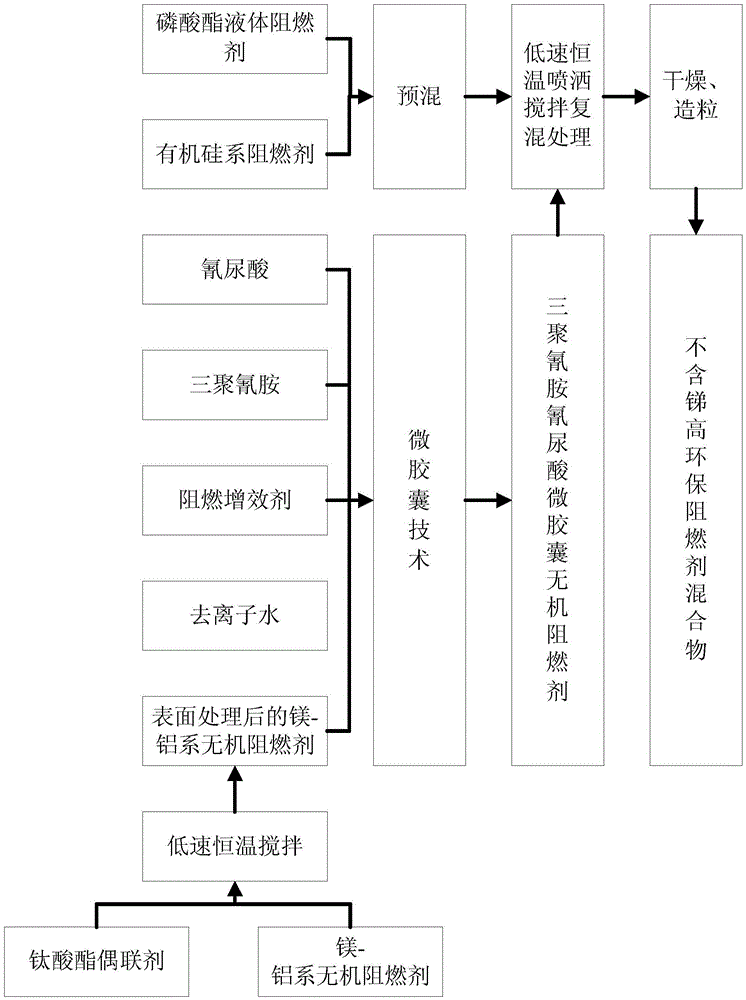

[0042] see figure 1 , the present invention provides a kind of preparation method of non-antimony high environmental protection flame retardant mixture, it specifically comprises the following steps:

[0043] (1) Preparation of raw materials

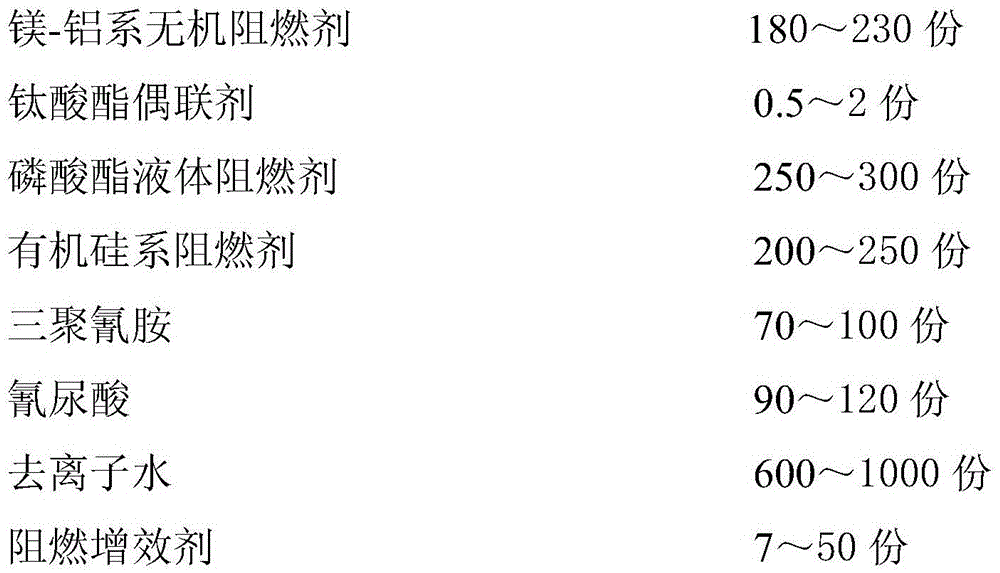

[0044] Prepare raw materials according to the following parts by weight:

[0045]

[0046] (2) Surface treatment of magnesium-aluminum inorganic flame retardants

[0047] Put the magnesium-aluminum-based inorganic flame retardant prepared in step (1) into the surface pretreatment device for stirring, heating and preheating for 5 to 10 minutes, then add the titanate coupling agent prepared in step (1), The rotation speed is 250-400 rpm, and the temperature is 30°C, stirring for 20-30 minutes to obtain a surface-treated magnesium-aluminum inorganic flame retardant;

[0048] (3) Preparation of melamine cyanuric acid microcapsule inorganic flame retardant

[0049] Add the magnesium-aluminum inorganic flame retardant after the surface tr...

Embodiment 2

[0073] The preparation method of the antimony-free high-environmental protection flame retardant mixture and the antimony-free high-environmental protection flame retardant mixture provided in this example have the same basic components and steps as in Example 1, except that:

[0074] A preparation method of antimony-free high-environmental protection flame retardant mixture, which specifically includes the following steps:

[0075] (1) Preparation of raw materials

[0076] Prepare raw materials according to the following parts by weight:

[0077]

[0078]

[0079] (2) Surface treatment of magnesium-aluminum inorganic flame retardants

[0080] Put the magnesium-aluminum inorganic flame retardant prepared in step (1) into the surface pretreatment device for stirring, and after heating and preheating for 8 minutes, add the titanate coupling agent prepared in step (1), and stir the bar at a speed of Stir for 20 minutes at 300 rpm and at a temperature of 30°C to obtain a s...

Embodiment 3

[0099] The preparation method of the antimony-free high-environmental protection flame retardant mixture and the antimony-free high-environmental protection flame retardant mixture provided in this example have the same basic components and steps as those in Examples 1 and 2, except that:

[0100] A preparation method of antimony-free high-environmental protection flame retardant mixture, which specifically includes the following steps:

[0101] (1) Preparation of raw materials

[0102] Prepare raw materials according to the following parts by weight:

[0103]

[0104] (2) Surface treatment of magnesium-aluminum inorganic flame retardants

[0105] Put the magnesium-aluminum inorganic flame retardant prepared in step (1) into the surface pretreatment device for stirring, and after heating and preheating for 5 minutes, add the titanate coupling agent prepared in step (1), and stir the bar at a speed of Stir for 25 minutes at 250 rpm and 30°C to obtain a surface-treated magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com