Guar gum fracturing fluid breaker, and preparation method and application thereof

A gel breaker and fracturing fluid technology, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., can solve the problems of residue damage to the formation, guar gum fracturing fluid breaking, and corrosion of pipeline equipment, etc. The effect of overcoming incomplete glue breaking and solving corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

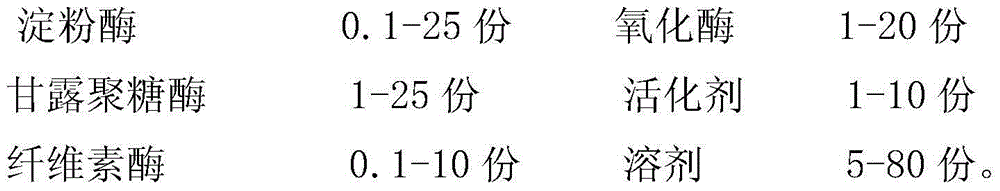

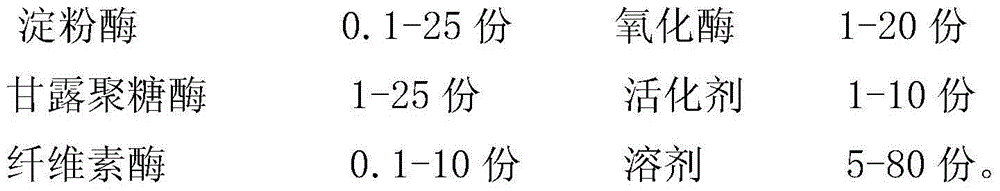

Method used

Image

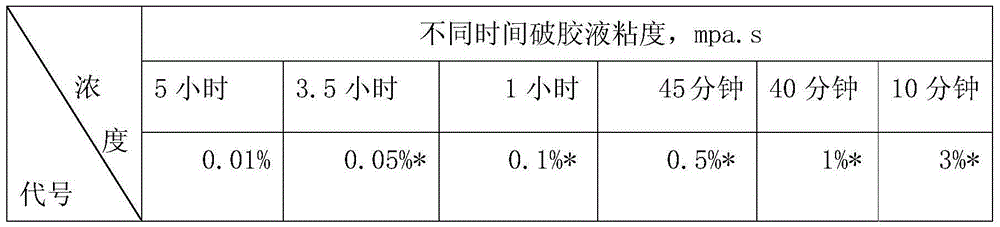

Examples

Embodiment 1

[0028] Solvent: 60 parts (wherein water, methanol, ethanol are respectively 20 parts, 30 parts, 10 parts),

[0029] Oxidase: 10 parts (wherein catalase and superoxide dismutase are respectively 10 parts and 0 parts),

[0030] Amylase: 0.1 part (of which α-amylase, β-amylase and γ-amylase are 0.1 part, 0 part, 0 part respectively),

[0031] Mannanase: 15 parts (of which acid-resistant, alkali-resistant and neutral β-mannanase are 15 parts, 0 parts, 0 parts respectively),

[0032] Tetraacetylethylenediamine: 5 parts,

[0033] Cellulase: 9.9 parts (including 7.9 parts, 2 parts, and 0 parts of exo-β-glucanase, endo-β-glucanase, and β-glucosidase, respectively).

Embodiment 2

[0035] Solvent: 70 parts (wherein water, methanol and ethanol are respectively 60 parts, 10 parts, 0 parts),

[0036] Amylase: 5 parts (of which α-amylase, β-amylase, γ-amylase are 4 parts, 0 parts, 1 part respectively),

[0037] Oxidase: 5 parts (wherein catalase and superoxide dismutase are 5 parts and 0 parts respectively),

[0038] Mannanase: 10 parts (of which acid-resistant, alkali-resistant, and neutral β-mannanase are 5 parts, 0 parts, and 5 parts respectively),

[0039] Tetraacetylethylenediamine: 5 parts,

[0040] Cellulase: 5 parts (including 5 parts, 0 parts, and 0 parts of exo-β-glucanase, endo-β-glucanase, and β-glucosidase, respectively).

Embodiment 3

[0042] Solvent: 75 parts (wherein water, methanol and ethanol are respectively 75 parts, 0 parts, 0 parts),

[0043] Amylase: 5 parts (of which α-amylase, β-amylase, γ-amylase are 4 parts, 0 parts, 1 part respectively),

[0044] Oxidase: 5 parts (wherein catalase and superoxide dismutase are respectively 0 and 5 parts),

[0045] Mannanase: 5 parts (of which acid-resistant, alkali-resistant and neutral β-mannanase are 5 parts, 0 parts, 0 parts respectively),

[0046] Tetraacetylethylenediamine: 5 parts,

[0047] Cellulase: 5 parts (including 5 parts, 0 parts, and 0 parts of exo-β-glucanase, endo-β-glucanase, and β-glucosidase, respectively).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com