End cam driving type axial plunger pump adopting rotating window oil distribution

An end face cam, drive type technology, applied in the parts of the pumping device for elastic fluid, piston pump, variable displacement pump parts, etc., can solve the problems of limited pump displacement, complex structure, unfavorable output flow, etc. Achieve the effect of improving reliability, simple transmission, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

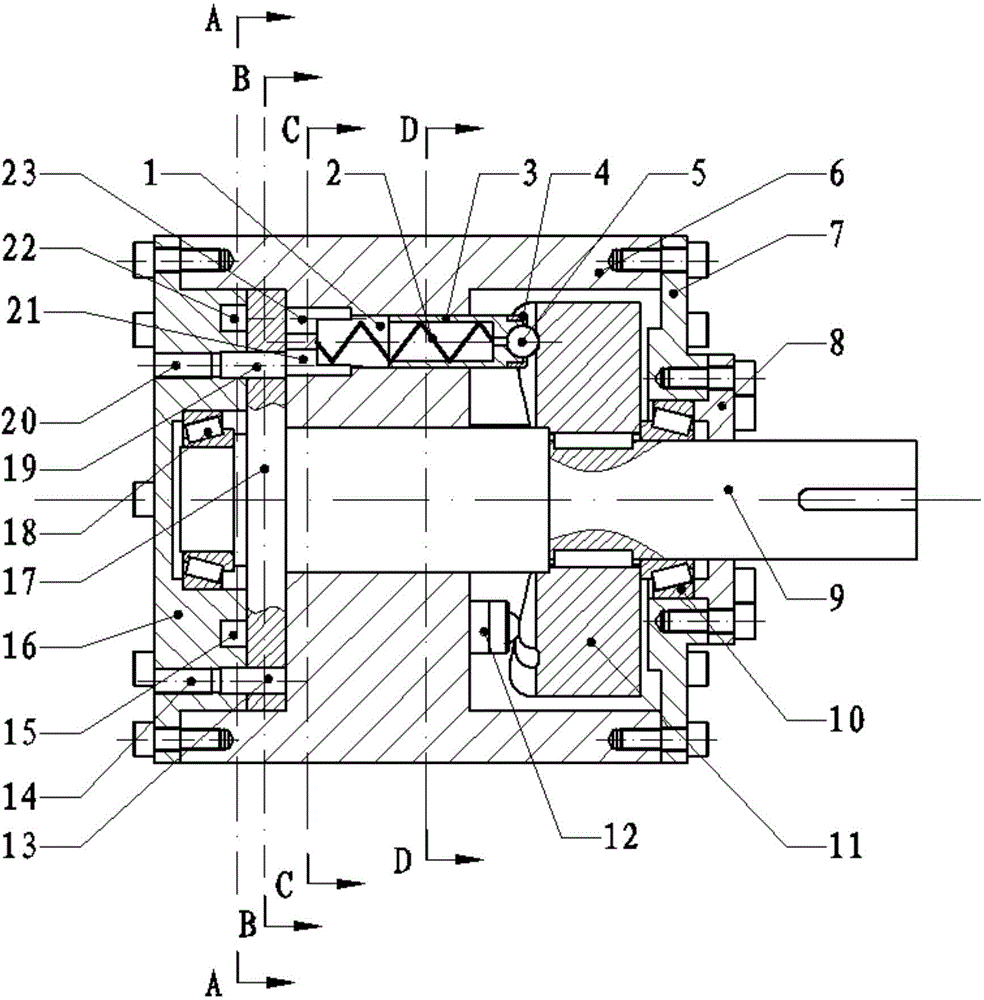

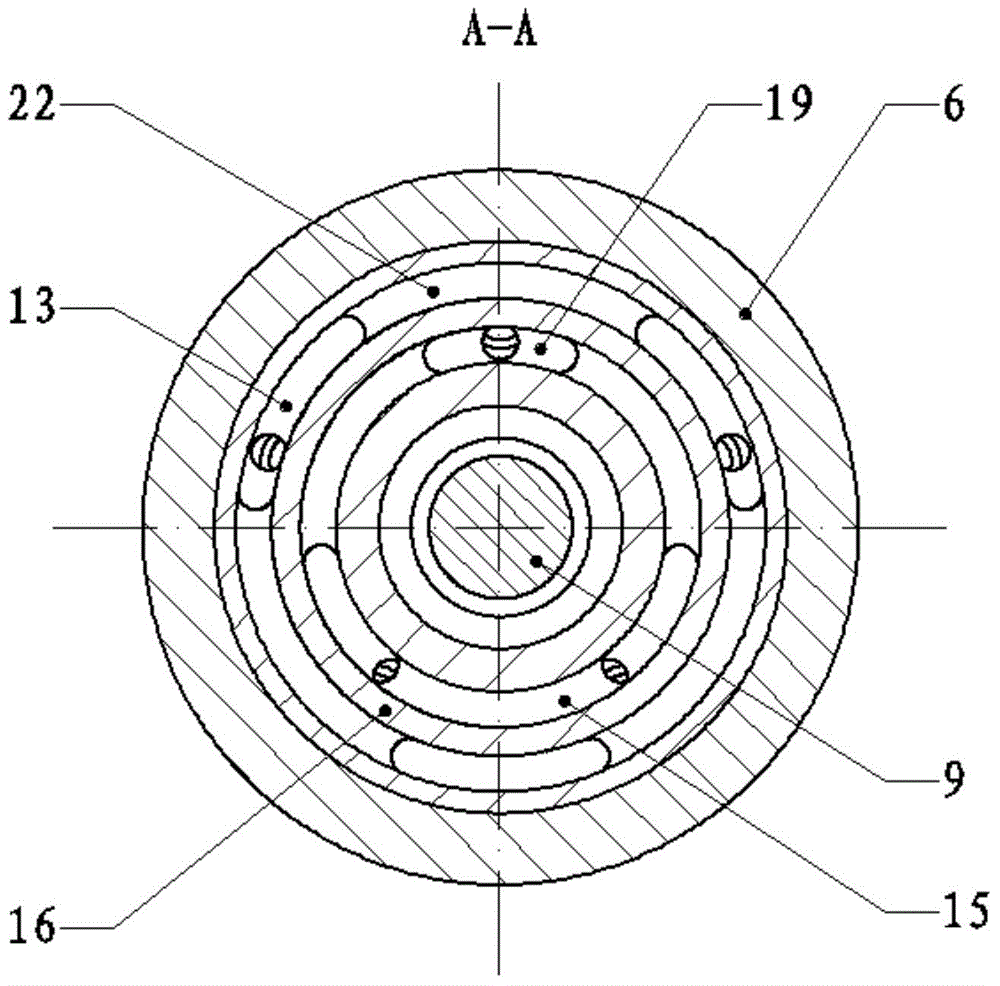

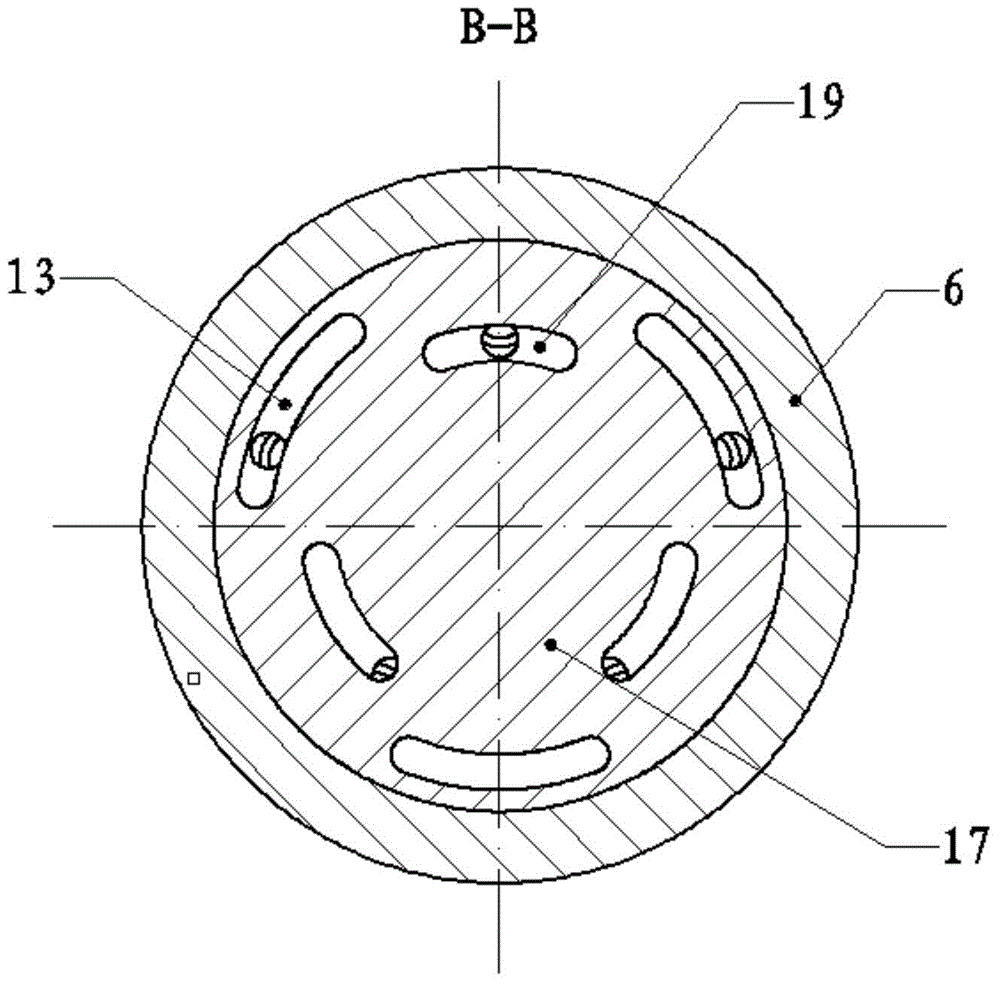

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , an end face cam-driven directional plunger pump that uses a rotating window to distribute oil, including an integrated pump body 6, a first pump end cover 16 and a second pump end cover 7 are fixedly installed on both sides of the integrated pump body 6, respectively , the transmission shaft 9 is installed inside the integrated pump body 6, and is supported on the first pump end cover 16 and the second pump end cover 7 through the first rolling bearing 18 and the second rolling bearing 10 respectively, and the shaft extension of the transmission shaft 9 The end is on the side of the second pump end cover 7, the driving cam 11 is installed on the transmission shaft 9, and is fixed with the transmission shaft 9 through a key connection, and the shoulder on the driving cam 11 is pressed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com