A plug-in pneumatic high-speed differential switch valve

A differential switch and cartridge valve technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problem that the pneumatic servo proportional system cannot reach the level of the hydraulic system, the control accuracy is low, and the control quality is low. problems, to achieve the effect of improving utilization, good flexibility, and good roundness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

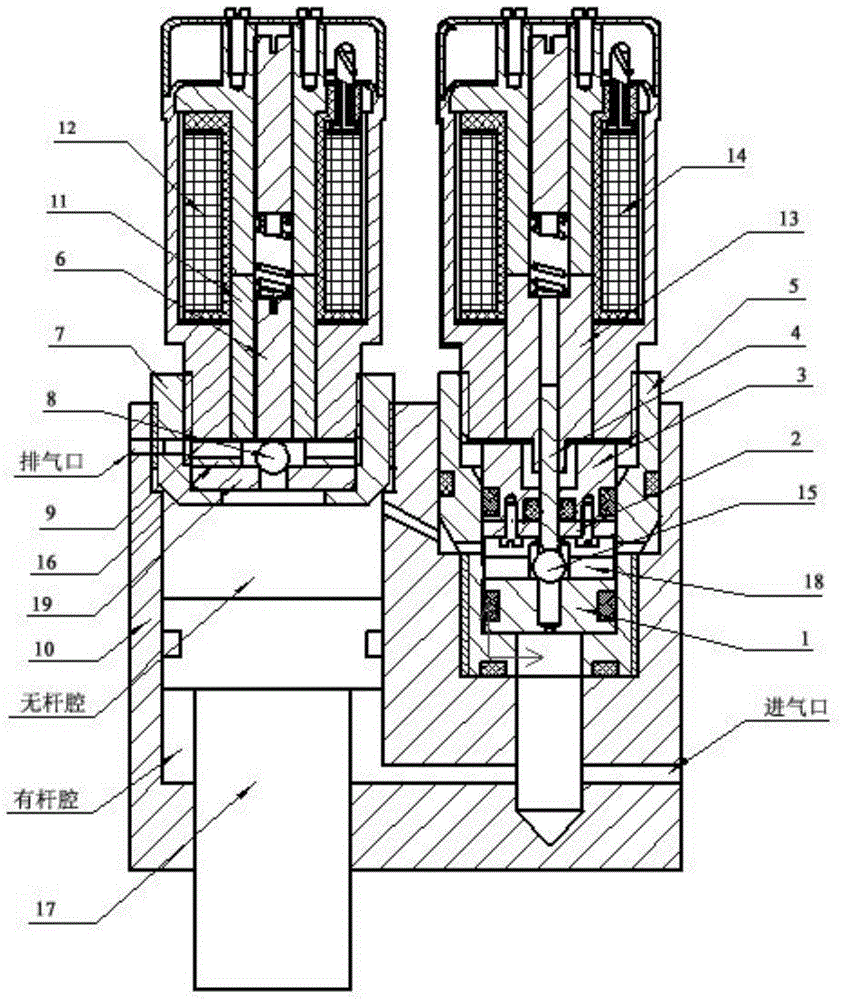

[0028] as attached figure 1 As shown, the present invention provides a plug-in pneumatic high-speed differential switch valve, the differential switch valve includes a valve seat 10, a piston 17, a cartridge valve assembly A and a cartridge valve assembly B, and the cartridge valve assembly B adopts The structure is different from the cartridge valve assembly A, which adopts the armature magnetic material and the valve core needle rod on it to form a whole to control the opening and closing of the spherical valve core.

[0029] The left half of the upper end surface of the valve seat 10 is processed with a step hole for installing the direct mounting valve assembly B, and the bottom surface of the step hole is processed with a through hole for installing the piston 17. The inner surface of the step hole above the step surface is processed with an internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com