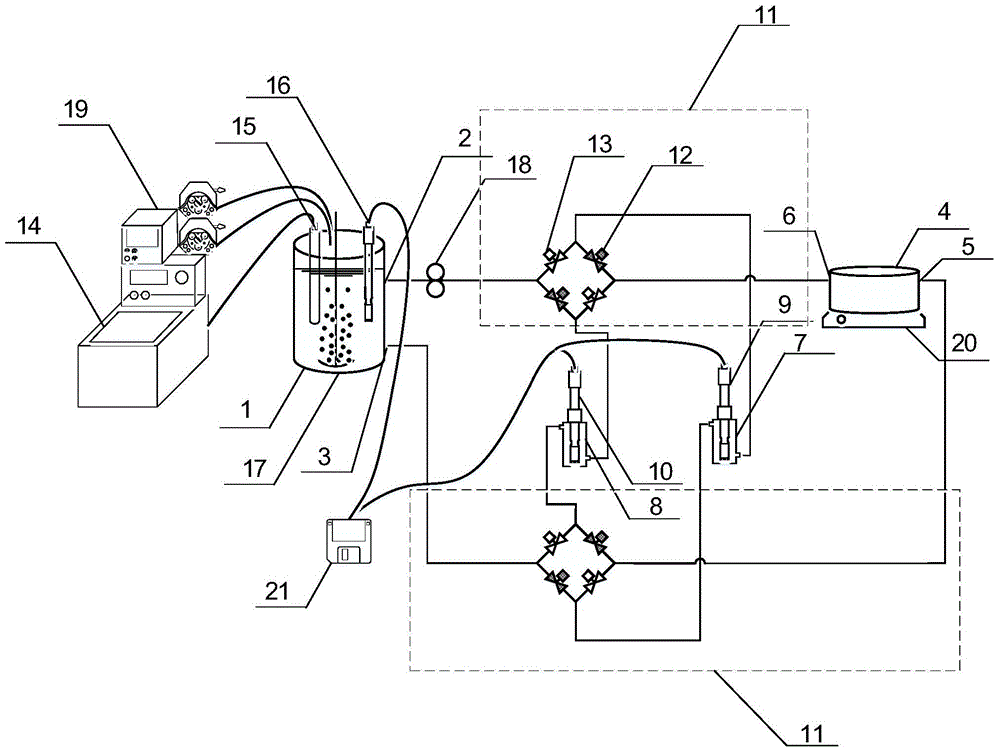

Active sludge aerobic respiration measuring device capable of being self-examined and corrected and application method thereof

A technology of activated sludge and measuring device, which is used in soil material testing, material inspection products, etc., can solve the problems of large measurement error and low test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] When using sodium acetate with a concentration of 200mgCOD / L as the organic substrate to test the oxygen consumption rate of the activated sludge aerobic process, proceed as follows:

[0074] (1) Add 6L of activated sludge into the aeration chamber, turn on the peristaltic pump, adjust the flow rate to 750ml / min, and make the activated sludge circulate through the pipeline flow control system in the aeration chamber, measurement chamber and breathing chamber.

[0075] (2) Set the control temperature to 20±0.5°C, control the pH value to 7.0±0.5, turn on the aeration pump, feed air into the aeration chamber, and turn on the magnetic stirrer at the bottom of the breathing chamber to make the mixture even.

[0076] (3) When the system temperature and pH value are stable, turn on the dissolved oxygen test sensor to measure the change of the dissolved oxygen concentration at the inlet and outlet of the breathing chamber. The measured values of the sensors are recorded every...

Embodiment 2

[0091] When using urban sewage as the organic substrate to test the oxygen consumption rate of the activated sludge aerobic process, proceed as follows:

[0092] (1) Add 4L of activated sludge into the aeration chamber, turn on the peristaltic pump, adjust the flow rate to 750ml / min, and make the activated sludge circulate in the aeration chamber, measurement chamber and breathing chamber through the pipeline flow control system.

[0093] (2) Set the control temperature to 20±0.5°C, control the pH value to 7.0±0.5, turn on the aeration pump, feed air into the aeration chamber, and turn on the magnetic stirrer at the bottom of the breathing chamber to make the mixture even.

[0094] (3) When the system temperature and pH value are stable, turn on the dissolved oxygen test sensor to measure the change of the dissolved oxygen concentration at the inlet and outlet of the breathing chamber. The measured values of the sensors are recorded every 5s.

[0095] (4) Heat the urban sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com