Method for preparing araneose transparent conductive electrode

A technology of transparent conductive electrodes and spider webs, which is applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of expensive preparation methods and increase production costs, and achieve the effect of simple process, less process and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

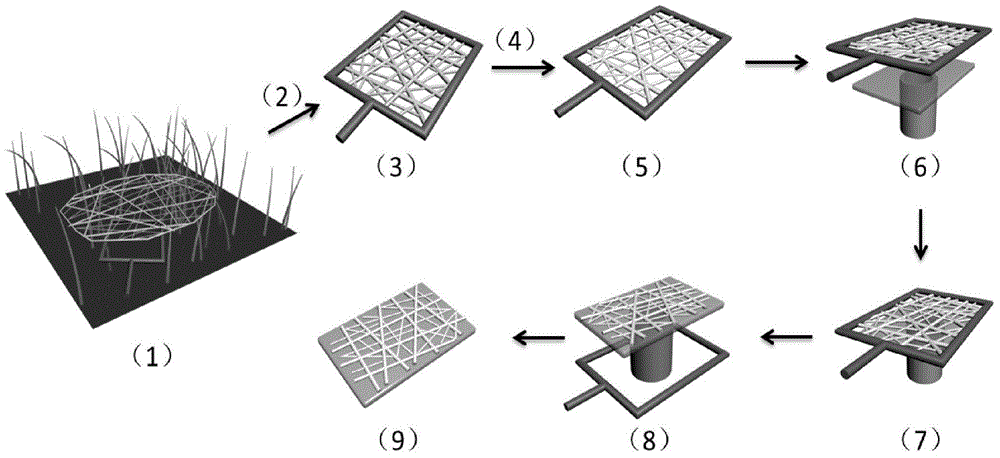

[0040] This embodiment provides a preparation method of a spider web-shaped transparent conductive electrode, such as figure 1 shown in the figure, where (1) means scooping up the natural spider web with a metal frame, (2) means lifting the metal frame up to pick up the spider web, (3) means the spider web laid on the metal frame, (4) means depositing metal Thin film, (5) represents the spider web electrode whose surface is covered with dense metal thin film, (6), (7), (8) represent the spider web electrode transferred to the substrate, (9) represents the spider web electrode on the substrate. Spider web-shaped transparent conductive electrode, the electrode sample is completed;

[0041] The detailed process of each step is as follows:

[0042] (1) Making a spider web template

[0043] Making a metal frame: In this embodiment, the spider web is the spider web of the labyrinth funnel spider (Agelena labyrinthica), and a metal frame is made according to the size of the spider ...

Embodiment 2

[0055] This embodiment provides a preparation method of a spider web-shaped transparent conductive electrode, such as figure 1 shown in the figure, where (1) means scooping up the natural spider web with a metal frame, (2) means lifting the metal frame up, and picking up the spider web (3) means the spider web laid on the metal frame, (4) means depositing a metal film , (5) represents the spider web electrode covered with dense metal film on the surface, (6), (7), (8) represent the spider web electrode transferred to the substrate, (9) represents the spider on the substrate Mesh transparent conductive electrode, the electrode sample is completed;

[0056] The detailed process of each step is as follows:

[0057] (1) Making a spider web template

[0058] Making a frame-shaped bracket: The spider web in this embodiment is the spider web of the labyrinth funnel spider (Agelena labyrinthica), and a frame-shaped bracket is made according to the size of the spider web. The shape o...

Embodiment 3

[0067] This embodiment provides a preparation method of a spider web-shaped transparent conductive electrode, such as figure 1 shown in the figure, where (1) means scooping up the natural spider web with a metal frame, (2) means lifting the metal frame up, and picking up the spider web (3) means the spider web laid on the metal frame, (4) means depositing a metal film , (5) represents the spider web electrode covered with dense metal film on the surface, (6), (7), (8) represent the spider web electrode transferred to the substrate, (9) represents the spider on the substrate Mesh transparent conductive electrode, the electrode sample is completed;

[0068] The detailed process of each step is as follows:

[0069] (1) Making a spider web template

[0070] Making a frame-shaped support: the spider web of the present invention is the spider web of the labyrinth funnel spider (Agelena labyrinthica), and the frame-shaped support is made according to the size of the spider web. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com