High-frequency multiple high voltage pulse generating method, high-frequency multiple high voltage pulse power supply and electric precipitator

A high-voltage pulse power supply and high-frequency pulse technology, applied in the field of high-frequency multiple high-voltage pulse power supply and electrostatic precipitator, high-frequency multiple high-voltage pulse generation, can solve the problems of single function of dust collector and expensive dust collector.

Inactive Publication Date: 2014-08-13

DALIAN TAIGEER ELECTRONICS TECH

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the dust collector in the form of pulse power supply is relatively expensive, and the technical intellectual property rights are owned by foreign countries

In addition, the dust collector in the form of pulse power supply has a single function and can only complete pulse power supply.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

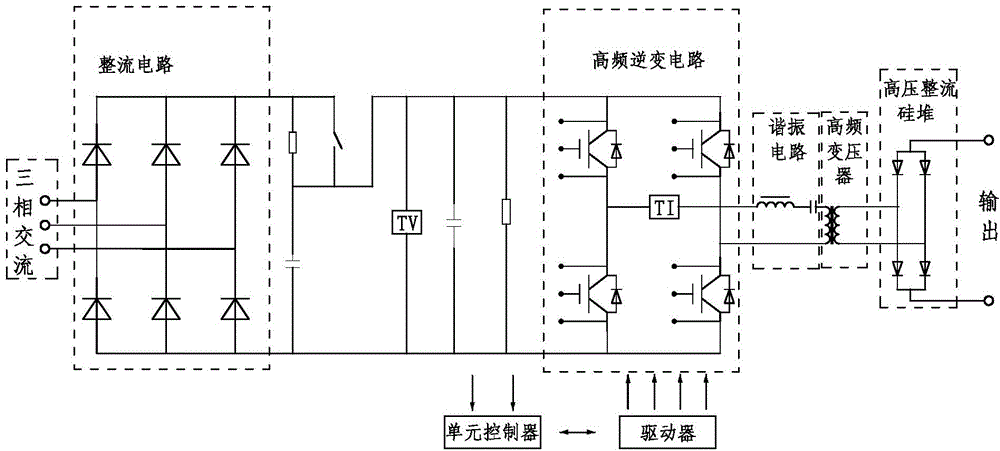

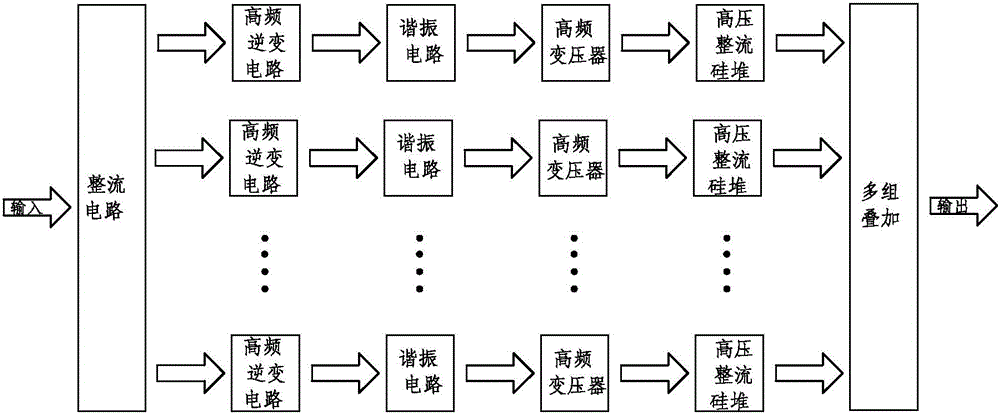

[0050] In a specific embodiment, the power supply is combined with four groups of IGBT full-bridge inverter independent power supplies with high-frequency multiple high-voltage pulse power supplies as an example for illustration:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

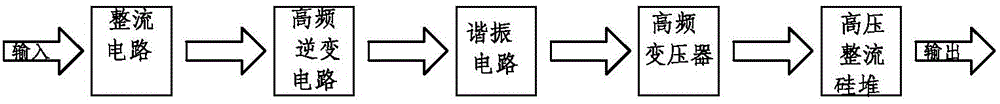

The invention discloses a high-frequency multiple high voltage pulse generating method, a high-frequency multiple high voltage pulse power supply and an electric precipitator. According to the description, a master control unit controls high-frequency pulse power supply units needing to work at a certain moment to simultaneously generate direct-current high-voltage pulses according to setting; in work, the master control unit controls the high-frequency pulse power supply units needing to work at a certain moment to simultaneously generate the direct-current high-voltage pulses according to setting, and the direct-current high-voltage pulses are superposed at a total output end to form multiple high voltage pulses. The high-frequency multiple high voltage pulse power supply integrates various power supply modes, and direct-current power supply, intermittent pulse power supply and direct-current superposed-pulse power supply can be achieved. Pulse voltages are superposed on the basis of an effective direct-current corona voltage, step pulse supply is achieved, and the pulse leading edge time is short. High-ratio resistance dust can be effectively collected, back corona can be inhibited, the collecting efficiency of fine dust (PM2.5) can be improved, and the high-frequency multiple high voltage pulse power supply is a new-generation power supply of the electric precipitator.

Description

technical field [0001] The invention relates to a method for generating high-frequency multiple high-voltage pulses, a high-frequency multiple high-voltage pulse power supply and an electric precipitator. Background technique [0002] Electrostatic precipitator has a development history of more than 100 years. Because of its unique advantages such as high dust removal efficiency, wide application range, low operating cost, safety and reliability, convenient use and no secondary pollution, it is the first choice for industrial dust removal equipment, especially In thermal power generation, metallurgy, building materials and other industries. The national "Emission Standards of Air Pollutants for Thermal Power Plants" intends to increase the emission standards of smoke and dust from 50mg / m3 to 30mg / m3, and to 20mg / m3 in key areas. Faced with increasingly stringent emission standards, many electrostatic precipitators in service cannot meet the requirements and have to undergo ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02M9/06B03C3/66

Inventor 王锋李晓峰

Owner DALIAN TAIGEER ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com