Enzyme-treated tea extract, and tea beverage

An extract and tea beverage technology, applied in the field of container-packed tea beverages, can solve the problems of the stabilizer affecting beverage flavor, etc., and achieve the effects of inhibiting precipitation and enhancing flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0069] The present invention is more specifically illustrated by the following examples, but the present invention is not limited to these examples.

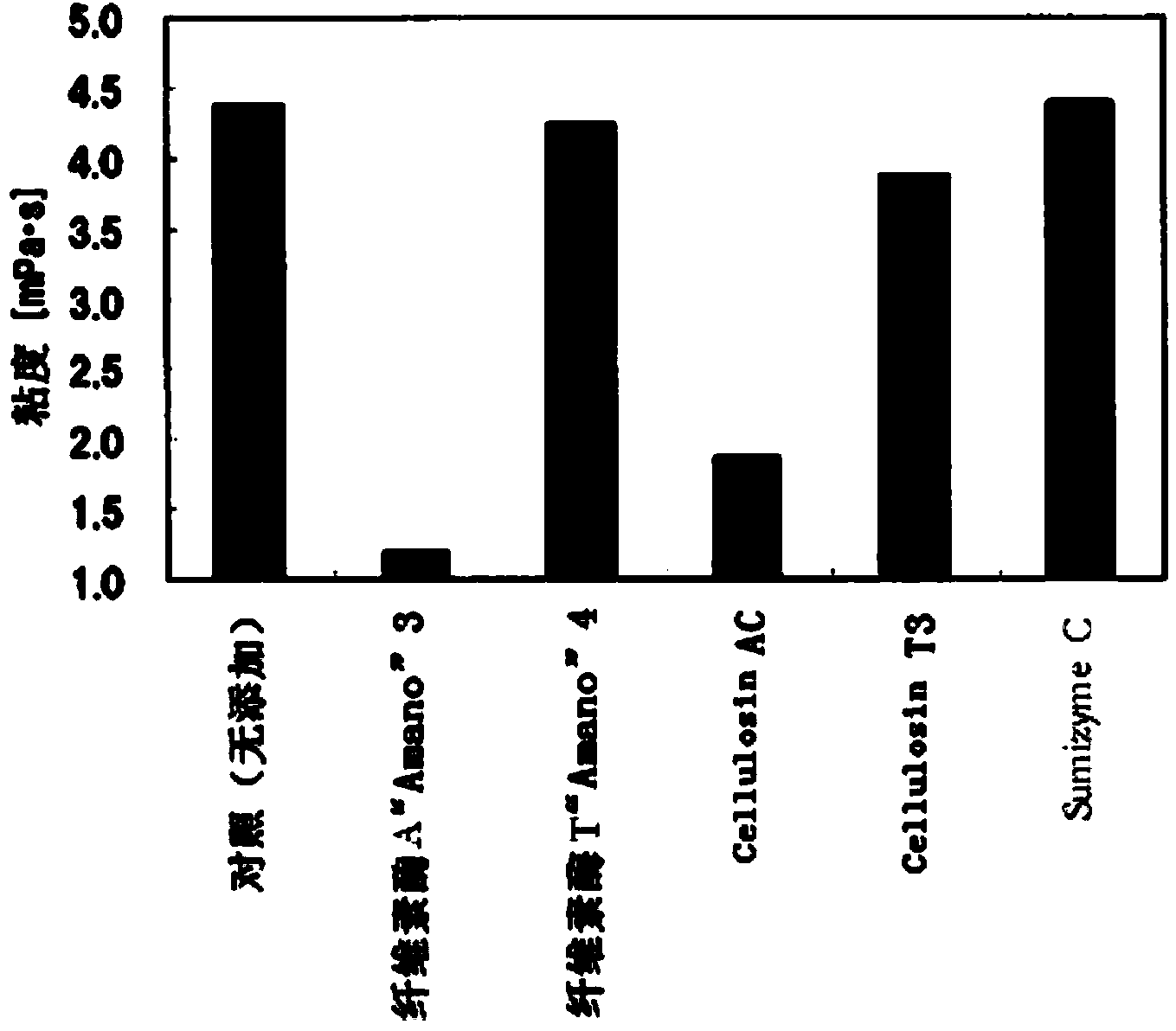

reference example 1

[0071] After adjusting pectin (trade name pectin (sugar-free), manufactured by Nacalai Tesque Co., Ltd.) to 0.5% by weight with acetate buffer solution pH 5.4, commercially available cellulase for food addition (trade name Cellulase A "Amano" 3 (manufactured by Amano Enzyme Co., Ltd.), product name Cellulase T "Amano" 4 (manufactured by Amano Enzyme Co., Ltd.), product name Cellulosin AC (manufactured by HBI Co., Ltd.), product name Cellulosin T3 ( (manufactured by HBI Corporation), brand name Sumizyme C (manufactured by Shin Nippon Chemical Industry Co., Ltd.)) was added to 1% by weight with respect to the pectin in the test solution. After reacting at 37°C for 16 hours, treat at 90°C for 10 minutes to inactivate the enzyme activity. Thereafter, the viscosity was measured at 24.5° C. with a tuning fork vibrating viscometer SV-A (manufactured by A&D Co., Ltd.). As a result, such as figure 1 As shown, the cellulase T "Amano" 4 and Sumizyme C basically do not produce viscosity...

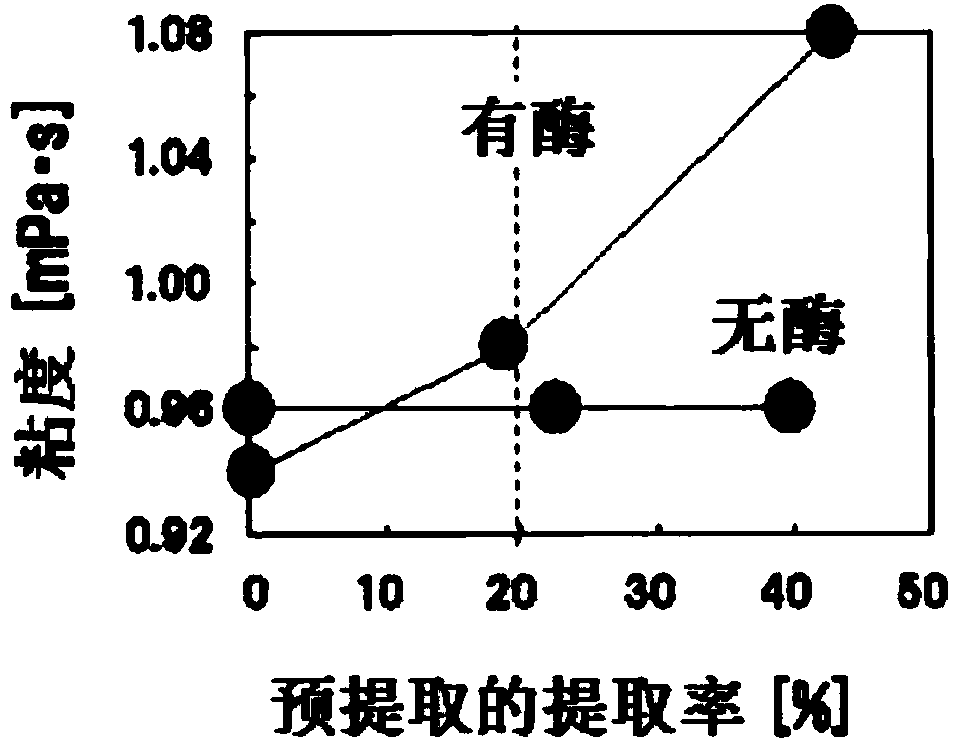

Embodiment 1

[0073] Extract 5 g of pulverized Sencha tea leaves with 500 g of hot water for 3 minutes once (20% extraction rate of soluble components) or twice (40% extraction rate of soluble components), perform solid-liquid separation, and add cellulase T "Amano" 4 (Amano Enzyme Co., Ltd.), made it 1% by weight with respect to the weight of tea leaves, and added 15 times the pure water of the weight of tea leaves. Furthermore, about 0.5% by weight of the weight of the tea leaves was added with L-ascorbic acid to adjust the pH to 4.6. Thereafter, the reaction was carried out at 37°C for 16 hours, and the enzyme activity was inactivated by treating at 90°C for 10 minutes to terminate the reaction. The tea enzyme-treated extract was recovered by solid-liquid separation, and the viscosity was measured with a tuning fork vibrating viscometer SV-A (manufactured by A&D Co., Ltd.). As a control, the same operation was carried out without adding the enzyme, and its viscosity was measured. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com