Method for generating hydrogen and oxygen by steam electrolysis

A technology for preparing hydrogen and steam, applied in chemical instruments and methods, through aromatics hydrorefining, separation methods, etc., can solve problems such as overvoltage and electrode delamination, and achieve the effect of improving impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

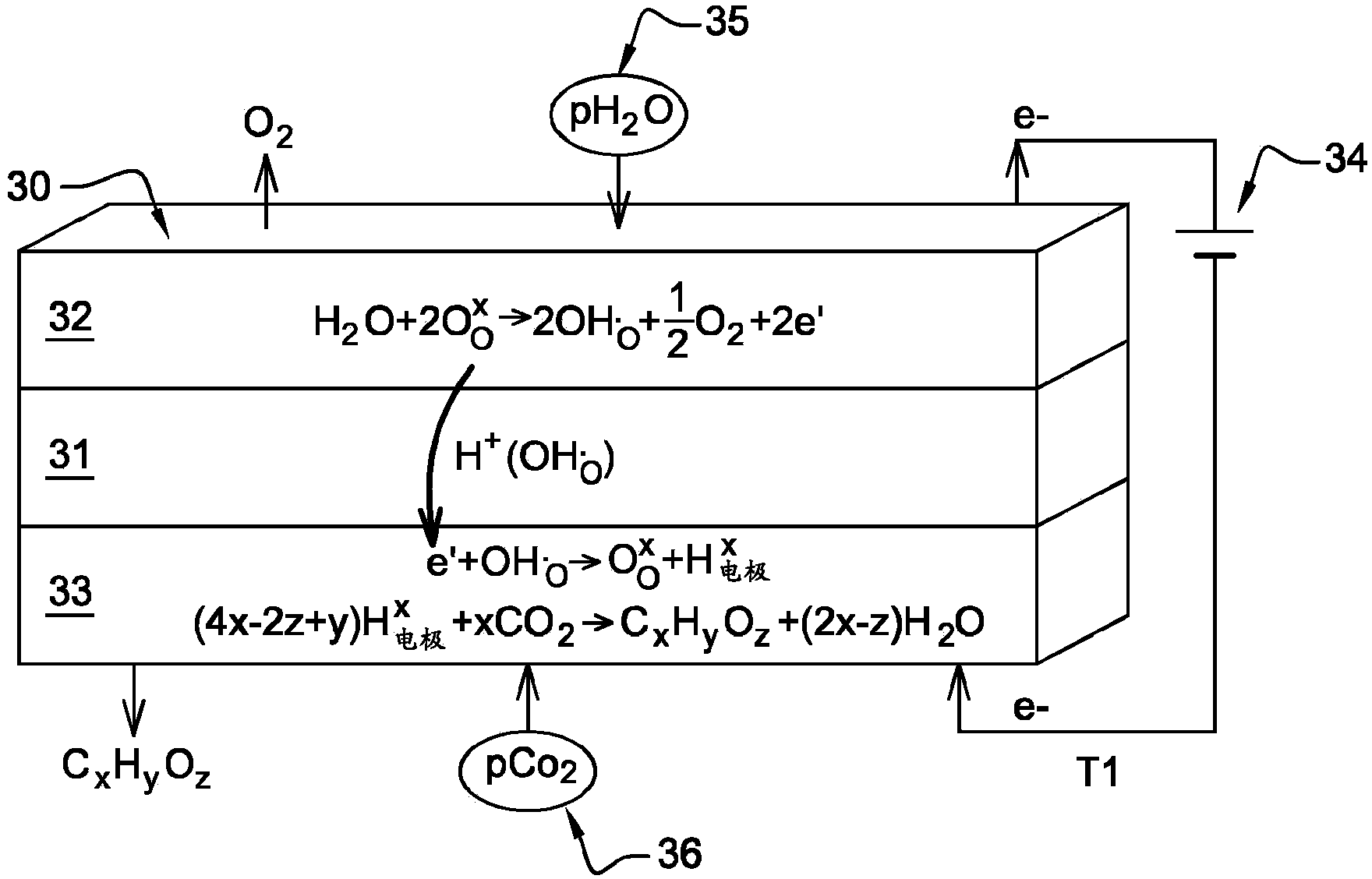

[0085] image 3 An electrolytic cell 30, also referred to as basic components, for carrying out the electrolytic process of the invention is represented in a general, schematic and simplified manner.

[0086] The electrolytic cell 30 has the figure 2 The device 20 has a similar structure. Thus, the pool 30 contains:

[0087] - anode 32;

[0088] - cathode 33;

[0089] - an electrolyte 31 formed by a proton-conducting electrolyte membrane;

[0090] - means 34 for inducing a current to circulate between the anode 32 and the cathode 33, wherein the current density is not less than 500 mA / cm 2 ;

[0091] - makes it possible to pass the steam pH under pressure through the anode 32 2 O is injected into the means 35 in the membrane 31 (the partial pressure and the relative vapor pressure of the stream are not less than 1 bar and preferably not less than 10 bar).

[0092] It should be noted that the terms partial pressure and relative pressure here refer to the injection pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com