A method and equipment for dealumination of base film

A base film and dealumination technology, which can be applied to cleaning methods using tools, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as unenvironmental protection, low production efficiency, and poor production environment, and reduce the use of clean water. , the effect of improving production efficiency and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

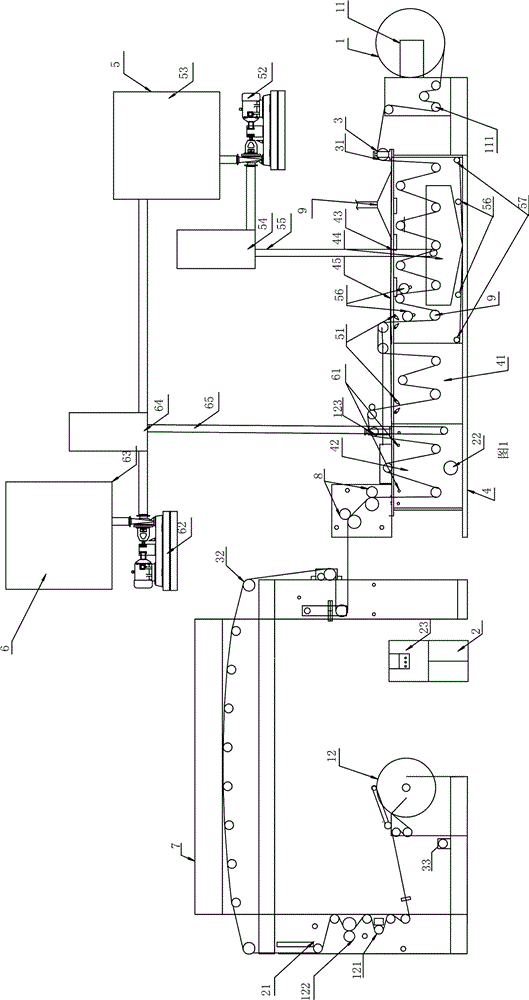

Image

Examples

Embodiment Construction

[0027] The method for base film dealumination in this preferred embodiment comprises the following steps:

[0028] a. Send the base film containing the aluminum-plated layer on the surface into the cleaning solution for aluminum washing;

[0029] b. Send the above-mentioned base film into clear water for cleaning;

[0030] c, drying the base film;

[0031] The method for washing aluminum in the step a is to send the above-mentioned base film into the cleaning solution of the first cleaning solution tank, let the aluminized layer on the surface of the base film react with the cleaning solution, then use a hair roller to scrub the surface of the base film, and then use The high-pressure water jet rinses the surface of the above-mentioned basement membrane, and then the basement membrane enters the second cleaning solution tank to allow the residual aluminum layer on the basement membrane surface to continue to react with the cleaning solution, and finally rinses the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com