Compound electrode machining method for improving efficiency of electric spark machining of turbine disc with blade tip shroud

A technology of combining electrodes and processing methods, applied in the field of aerospace or aviation special processing, can solve the problems of long effective processing time of equipment and low EDM processing efficiency, so as to increase the machining discharge area, improve the EDM efficiency of turbine disks, The effect of improving the utilization rate of machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

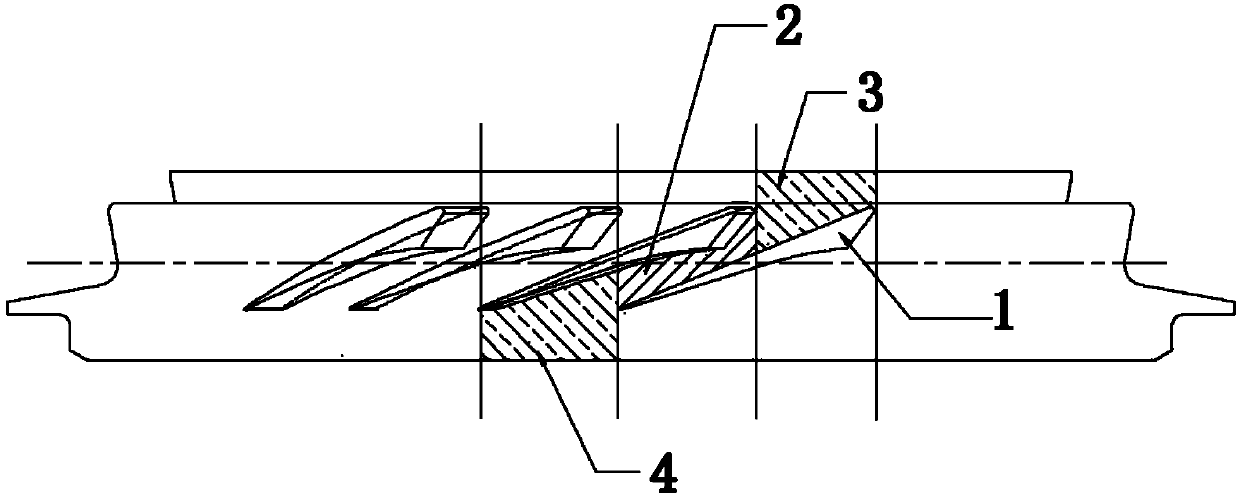

[0031] Such as figure 1 As shown, 21 blades are evenly distributed on the diameter of the turbine disk with blade shroud Φ220mm, and the inlet and outlet are at an angle of 10 degrees relative to the axis. The blades are not only slender but also have a large grid pitch. According to calculations, the total length of a single blade is about 61 mm, the center of gravity is located at the center of the trailing edge of the blade, most of the blades deviate from the centerline of the impeller, and the blade spans the circumference of 17.14°. This structure puts forward higher requirements for electrode design.

[0032] A combined electrode machining method for improving the EDM efficiency of a turbine disk with a shroud according to the present invention is adopted, and the blade channel includes an inlet area 3, a channel throat area 2, and an outlet area 4;

[0033] It includes the following steps:

[0034] (a) Rough machining blade channel

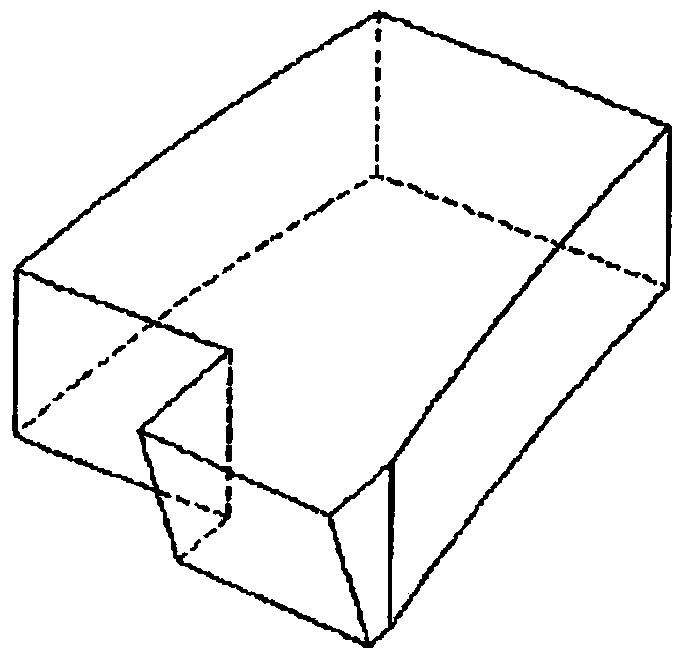

[0035] Such as Figure 5 As show...

Embodiment 2

[0057] A combined electrode machining method for improving the EDM efficiency of a turbine disk with a shroud according to the present invention is adopted, and the blade channel includes an inlet area 3, a channel throat area 2, and an outlet area 4;

[0058] It includes the following steps:

[0059] (a) Rough machining blade channel

[0060] Such as Figure 6 As shown, use the combined electrode on the left and the combined electrode on the right to machine the entrance area 3 and the exit area 4 from the left and right sides of the turbine disk respectively; quantity;

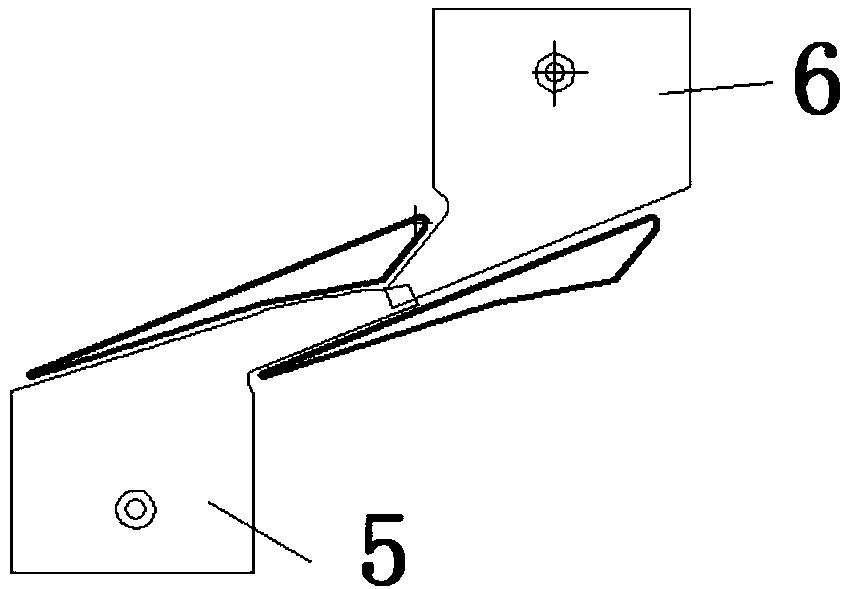

[0061] The left combined electrode combines four electrodes together through the connecting block to form the left combined electrode, and the assembly position of the electrode and the connecting block corresponds to the position and angle of the blade channel of the corresponding turbine disk; the design of the left combined electrode adopts Based on the profiling design principle of the blade channel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com