Laser-engraving transfer printing technology

A technology of transfer printing and transfer printing paper, applied in the field of laser engraving and transfer printing technology, can solve the problems of unstable printing effect and poor printing effect, and achieve the effect of stable printing effect and good printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

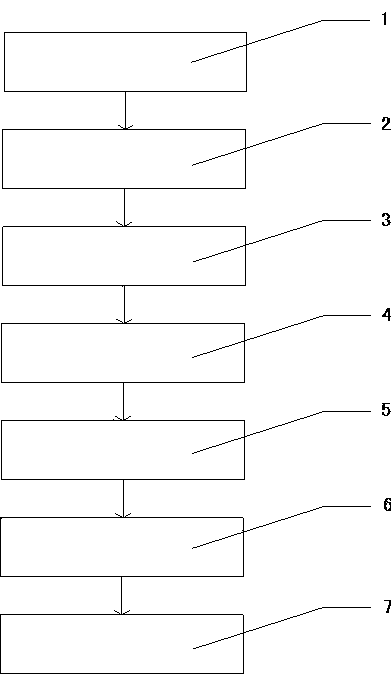

[0029] The laser engraving transfer printing process of the present invention comprises the following steps successively;

[0030] Applying photosensitive glue: roll coating photosensitive glue on the transfer printing paper;

[0031] Drying of photosensitive glue: Put the transfer printing paper coated with photosensitive glue into a dryer for drying at a drying temperature of 150°;

[0032] Laser irradiation: put the dried transfer printing paper into the printing machine, and irradiate it under the laser;

[0033] Sizing: add color paste to the transfer printing paper after laser irradiation;

[0034] Color paste drying: drying the transfer printing paper after sizing;

[0035] Thermal transfer printing of printing machine: Arrange the prepared transfer printing paper and raw materials into the printing machine to complete the thermal transfer printing of the printing machine.

[0036] In this way, the photosensitive adhesive on the transfer printing paper has a general ...

Embodiment 2

[0038] The laser engraving transfer printing process of the present invention comprises the following steps successively;

[0039] Applying photosensitive glue: roll coating photosensitive glue on the transfer printing paper;

[0040] Drying of photosensitive glue: Put the transfer printing paper coated with photosensitive glue into a dryer for drying at 200°C;

[0041] Laser irradiation: put the dried transfer printing paper into the printing machine, and irradiate it under the laser;

[0042] Sizing: add color paste to the transfer printing paper after laser irradiation;

[0043] Color paste drying: drying the transfer printing paper after sizing;

[0044] Thermal transfer printing of printing machine: Arrange the prepared transfer printing paper and raw materials into the printing machine to complete the thermal transfer printing of the printing machine.

[0045] In this way, the photosensitive adhesive on the transfer printing paper has a general drying effect.

Embodiment 3

[0047] In order to better prepare transfer printing paper, the laser engraving transfer printing process of the present invention comprises the following steps in sequence;

[0048] Applying photosensitive glue: roll coating photosensitive glue on the transfer printing paper;

[0049] Drying of photosensitive glue: Put the transfer printing paper coated with photosensitive glue into a dryer for drying at 190°;

[0050] Laser irradiation: put the dried transfer printing paper into the printing machine, and irradiate it under the laser;

[0051] Sizing: add color paste to the transfer printing paper after laser irradiation;

[0052] Color paste drying: drying the transfer printing paper after sizing;

[0053] Thermal transfer printing of printing machine: Arrange the prepared transfer printing paper and raw materials into the printing machine to complete the thermal transfer printing of the printing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com