Method and system for 2D/3D microstructure texture decoration on surface of raw material

A microstructure texture, 2D\3D technology, applied in the field of image processing, can solve the problems of technical process blockade, long, must be completed at one time, transfer, etc., to achieve the effect of simple production equipment, low development cost, and short development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

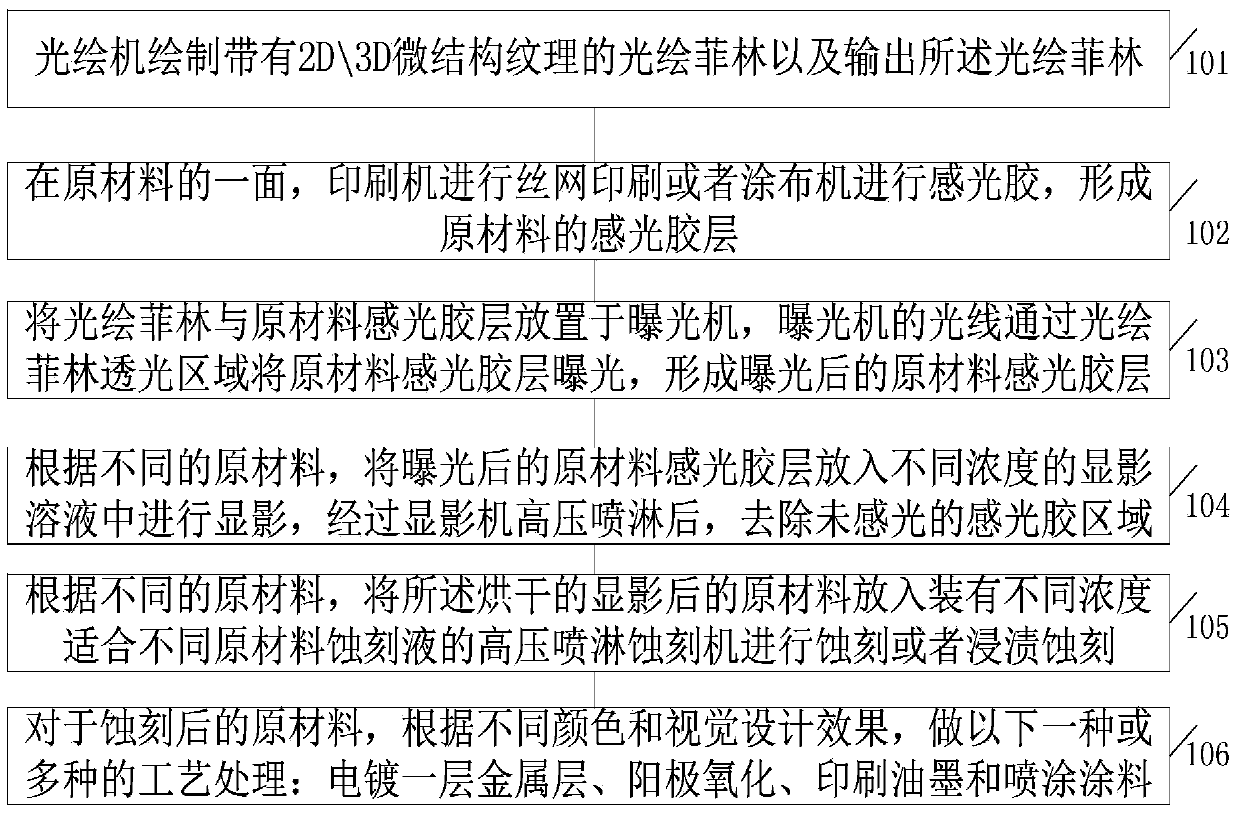

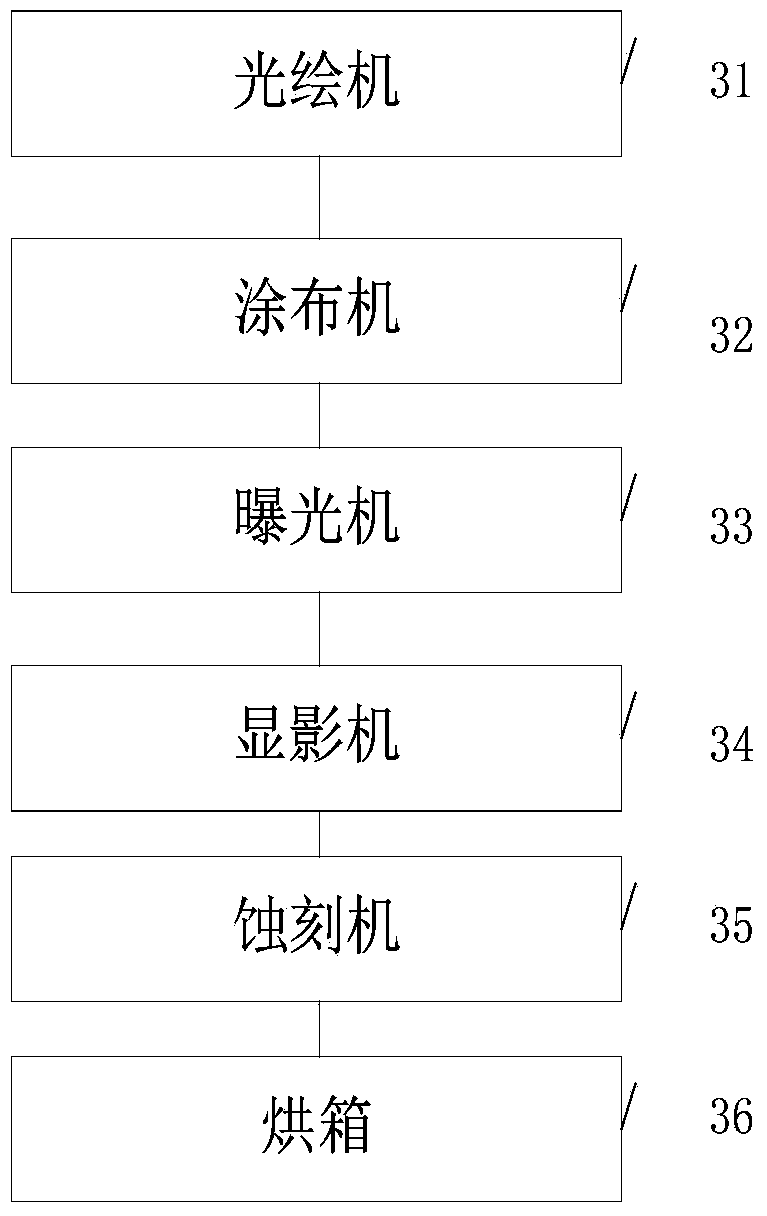

[0027] see figure 1 and figure 2 As shown, a method for 2D\3D microstructure texture decoration on the surface of raw materials, including

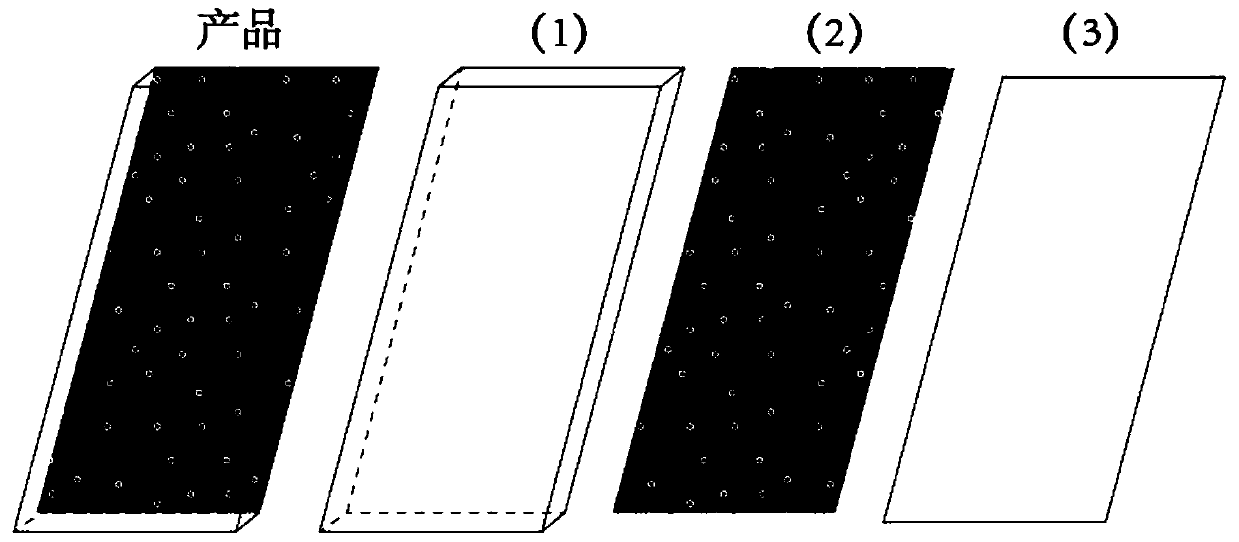

[0028] Step 101: A high-precision photoplotter draws a photopainted film with an accuracy of 25400dpi and outputs the photopainted film. The photopainted film is as follows: figure 2 as shown in (2).

[0029] For example: the photopainting film microstructure texture can be combined from a line width of 0.01mm to a line width of 0.08mm. The precision of the high-precision photoplotter is 25400DPI, and the resolution of the output photopainting film is 25400DPI.

[0030] Step 102: On one side of the raw material, the printing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com