Food-grade anti-corrosion lining rubber plate and preparation method thereof

A technology of anti-corrosion lining and rubber sheet, applied in the fields of anti-corrosion lining rubber sheet and food-grade anti-corrosion lining rubber sheet, can solve the problems of high price, difficult to promote, large investment cost, etc., and achieve low cost, safe and reliable processing technology, and mechanical properties. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

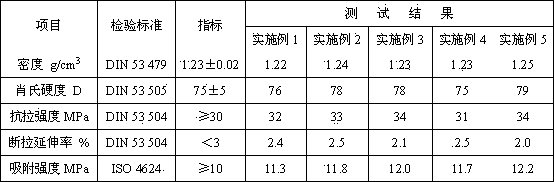

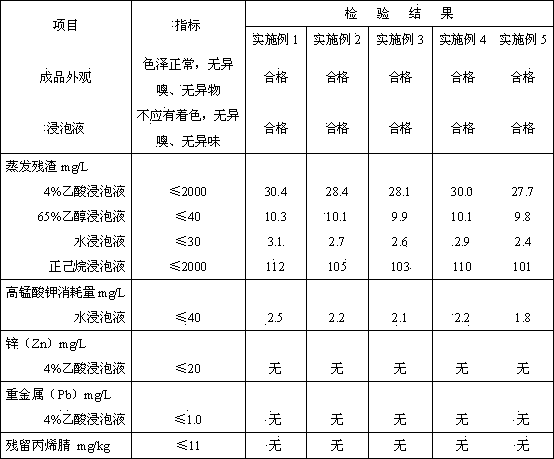

Examples

Embodiment 1

[0014] 1. Ingredients

[0015] 1# natural rubber: 70g

[0016] SBR 1502: 30g

[0017] Peptizer: 2g

[0018] High styrene: 10g

[0019] Sulfur: 30g

[0021] Carbon black N550: 10g

[0023] Stearic acid: 1.5g

[0024] Accelerator DOTG: 1g

[0025] 2. Preparation method

[0026] Add 1# natural rubber to the internal mixer, and after masticating for 1 minute, put in the peptizer, discharge the rubber when the temperature reaches 140°C, cool down the temperature 3-4 times through the open mixer, and drop it to 40°C to obtain the masticated rubber , then put the plasticized rubber into the internal mixer, add styrene-butadiene rubber 1502, high styrene, sulfur, graphite powder, carbon black N550, stearic acid and accelerator DOTG in sequence, and discharge the rubber after mixing. The temperature of the rubber discharge is 80 ℃, and then cooled 3-4 times through the open mill to obtain the rubber compound, and fina...

Embodiment 2

[0028] 1. Ingredients

[0029] 1# natural rubber: 75g

[0030] SBR 1502: 25g

[0031] Peptizer: 3g

[0032] High styrene: 12g

[0033] Sulfur: 35g

[0034] Graphite powder: 10g

[0035] Carbon black N550: 15g

[0037] Stearic acid: 2g

[0038] Accelerator DOTG: 1.5g

[0039] 2. Preparation method

[0040] Add 1# natural rubber to the internal mixer, after masticating for 1 minute, put in the peptizer, discharge the rubber when the temperature reaches 140°C, cool down the temperature 3-4 times through the open mixer, and drop it to 45°C to obtain the masticated rubber , then put the plasticized rubber into the internal mixer, add styrene-butadiene rubber 1502, high styrene, sulfur, graphite powder, carbon black N550, stearic acid and accelerator DOTG in sequence, and discharge the rubber after mixing. The temperature of the rubber discharge is 80 ℃, and then cooled 3-4 times through the open mill to obtain the rubber compound, and finally ...

Embodiment 3

[0042] 1. Ingredients

[0043] 1# natural rubber: 80g

[0044] SBR 1502: 20g

[0045] Peptizer: 3g

[0046] High styrene: 15g

[0047] Sulfur: 35g

[0048] Graphite powder: 25g

[0049] Carbon black N550: 25g

[0050] Magnesium oxide: 5g

[0051] Stearic acid: 1g

[0052] Accelerator DOTG: 2g

[0053] 2. Preparation method

[0054] Add 1# natural rubber to the internal mixer, after masticating for 2 minutes, put in the peptizer, discharge the rubber when the temperature reaches 140°C, cool down the temperature 3-4 times through the open mixer, and drop it to 40°C to obtain the masticated rubber , then put the plasticized rubber into the internal mixer, add styrene-butadiene rubber 1502, high styrene, sulfur, graphite powder, carbon black N550, stearic acid and accelerator DOTG in sequence, and discharge the rubber after mixing. The temperature of the rubber discharge is 80 ℃, and then cooled 3-4 times through the open mill to obtain the rubber compound, and finally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com