Low-temperature hydrolysis method for removing carbonyl sulfide in liquefied petroleum gas

A technology for liquefied petroleum gas and carbonyl sulfide, which is applied in the field of carbonyl sulfide removal and low-temperature hydrolysis for carbonyl sulfide removal, which can solve the problems of reduced catalyst life and achieve long service life, high hydrolysis conversion rate, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

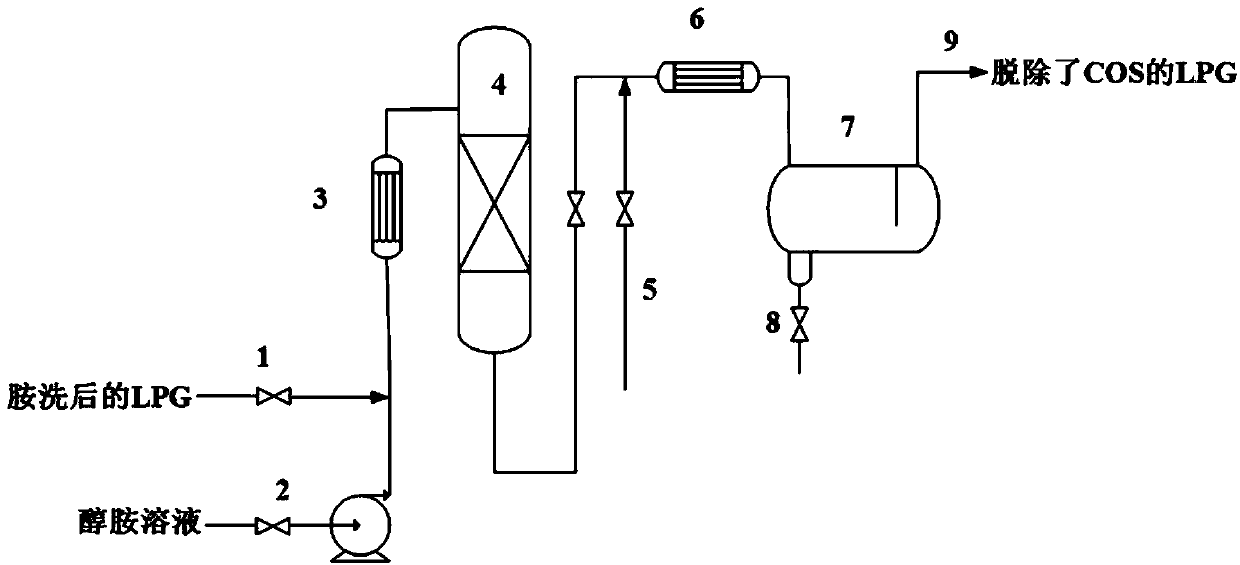

[0036] This embodiment provides a low-temperature hydrolysis method for removing carbonyl sulfide in liquefied petroleum gas, and its specific process flow is as follows figure 1 As shown, it specifically includes the following steps: the LPG raw material after amine washing enters the system from the first injection port 1, and the alcohol amine solution enters the system from the second injection port 2, and the two are mixed in the first static mixer 3 Evenly, enter the COS hydrolysis reactor 4 with a volume of 10mm×300mm, contact with a COS hydrolysis catalyst (5mL) to react, remove COS and hydrogen sulfide in LPG, and obtain a reaction mixture;

[0037] The reaction mixture enters the settling tank 7 after being mixed with the tap water entered by the third sample inlet 5 in the second static mixer 6, and the alcoholamine solution and tap water are settled down, and are discharged from the raffinate discharge port 8, and the COS after the COS is removed LPG flows out from...

Embodiment 2

[0044] This example provides a low-temperature hydrolysis method for removing carbonyl sulfide in liquefied petroleum gas, and the specific method is similar to that of Example 1.

[0045] Based on 100% mass percentage, the composition of the carbonyl sulfide hydrolysis catalyst used is: 10% MgO, 90% γ-Al 2 o 3 +TiO 2 (γ-Al 2 o 3 Content is 94%, TiO 2 The content is 6%); the particle size of the catalyst is 20-40 mesh.

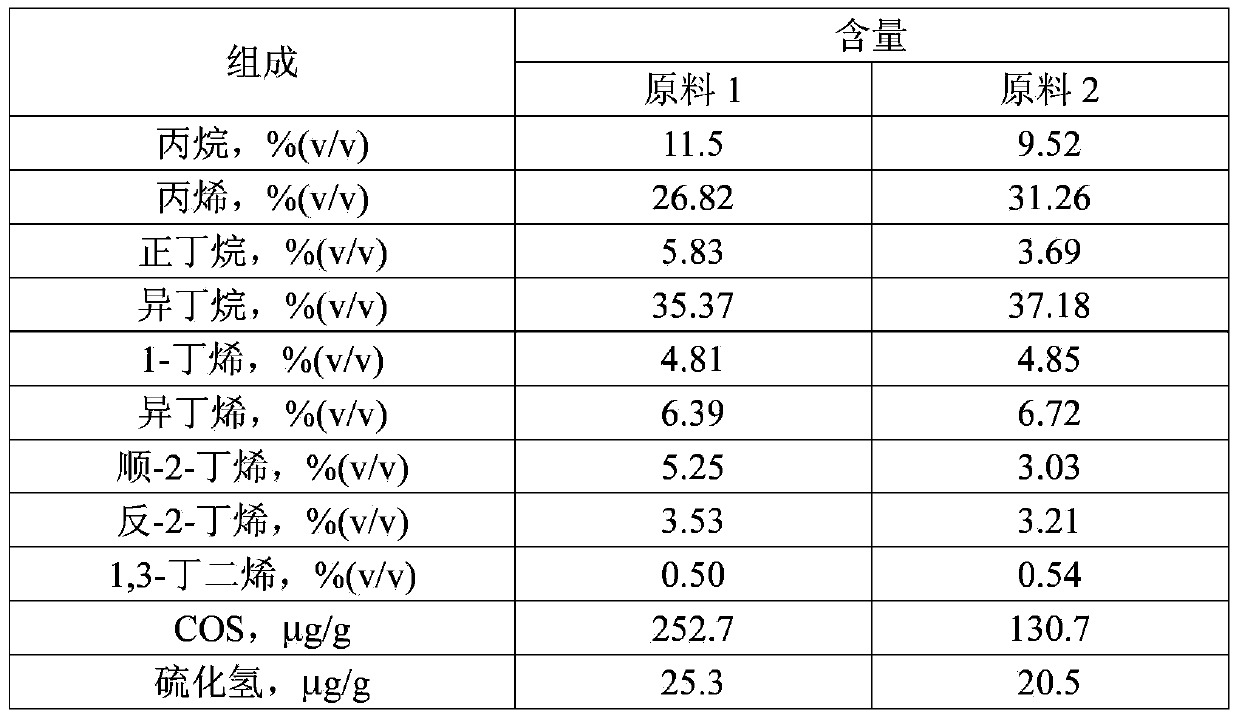

[0046] COS hydrolysis reaction evaluation conditions: the adopted LPG raw material is raw material 1, its properties are shown in Table 1, the reaction temperature is 30 ° C, the pressure is 1.0 MPa, and the concentration is 30 wt %. The addition of N-methyldiethanolamine solution is 5wt% of LPG, the volumetric space velocity of LPG is 6h -1 .

[0047] The calculation results show that the COS content in the LPG after COS removal is reduced from 252.7 μg / g to 3.8 μg / g, the hydrogen sulfide content is 0 μg / g, and the COS removal rate is 98.5%.

Embodiment 3

[0049] This example provides a low-temperature hydrolysis method for removing carbonyl sulfide in liquefied petroleum gas, and the specific method is similar to that of Example 1.

[0050] Based on 100% mass percentage, the composition of the carbonyl sulfide hydrolysis catalyst used is: 10wt% ZnO, 90wt% γ-Al 2 o 3 +TiO 2 (γ-Al 2 o 3 Content is 92wt%, TiO 2 The content is 8wt%); the particle size of the catalyst is 20-40 mesh.

[0051] COS hydrolysis reaction evaluation conditions: the adopted LPG raw material is raw material 1, its properties are shown in Table 1, the reaction temperature is 30 ° C, the pressure is 1.0 MPa, and the concentration is 30 wt %. The addition of N-methyldiethanolamine solution is 5wt% of LPG, the volumetric space velocity of LPG is 4h -1 .

[0052] The calculation results show that the COS content in the LPG after COS removal is reduced from 252.7 μg / g to 5.3 μg / g, the hydrogen sulfide content is 0 μg / g, and the COS removal rate is 97.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com