Retractable horizontal oil well packer

A technology for packers and oil wells, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve the problems of hindering the recovery of rubber sleeves, input of manpower and material resources, and increase of oil production costs, etc., and achieve fracturing stuck Low well rate, improved oil production efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

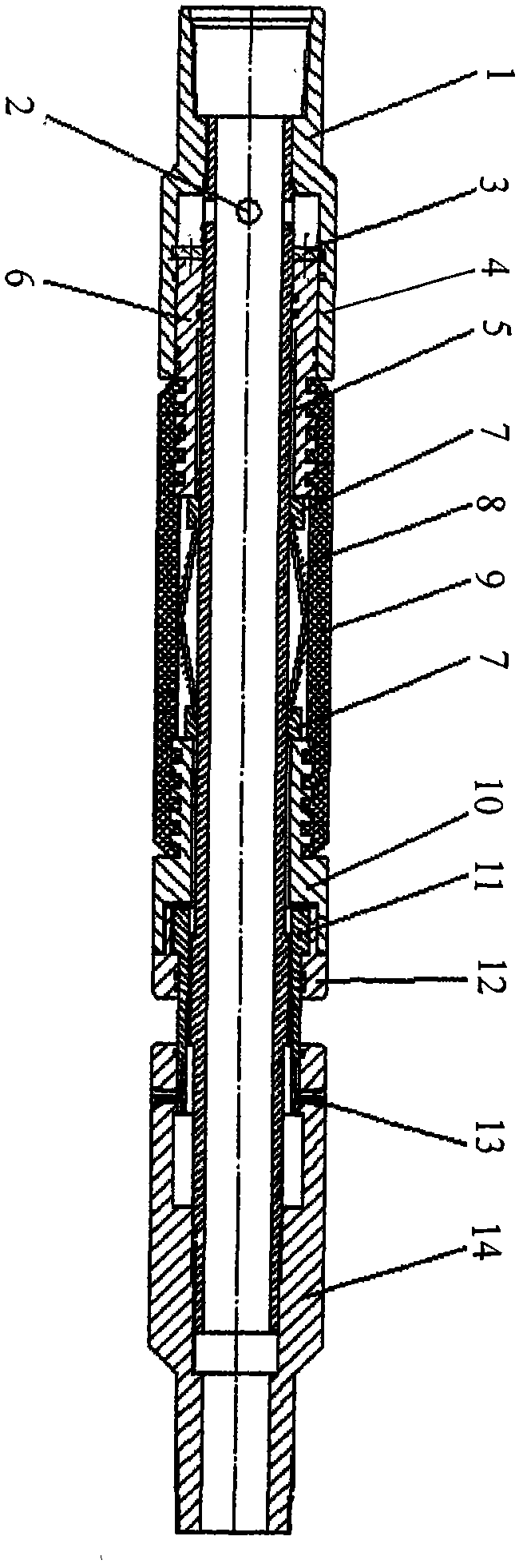

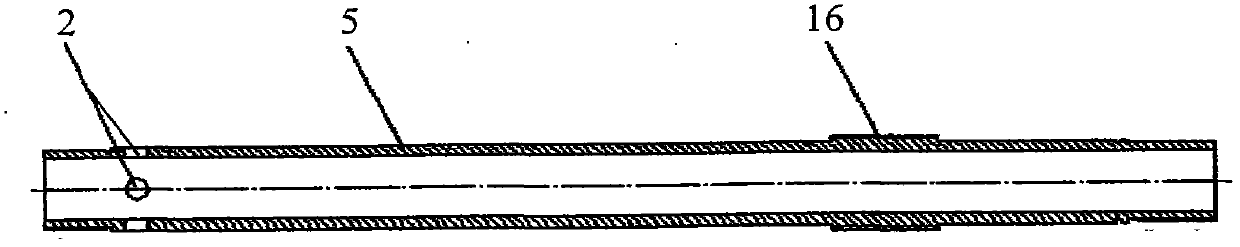

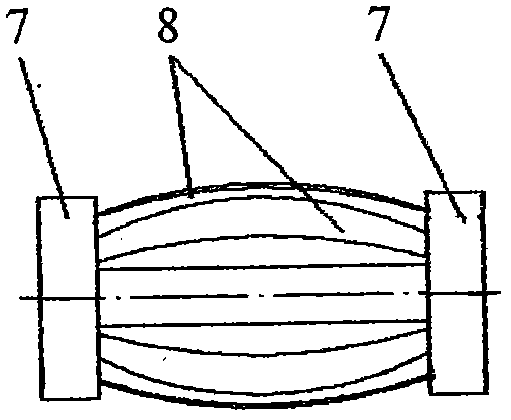

[0015] Depend on figure 1 , figure 2 It can be seen that the retractable horizontal oil well packer of the present invention includes a tubular left joint 1 and a right joint 14, wherein the right end of the left joint 1 is connected with the piston sleeve 4 as a whole, and the connection between the left joint 1 and the piston sleeve 4 It is coaxially connected with the left end of the central tube 5, and several liquid inlet holes 2 are arranged on the wall of the central tube 5 at the connecting end; on the outer diameter of the central tube 5, the sleeve piston 6 and the drum-shaped flower basket expansion tube are sequentially slid. , pulling seat 10 and rotating suit left-handed slider 11; the left end of the piston cylinder 6 is fitted with the piston sleeve 4 sliding plug seals, and the left end face of the piston cylinder 6 is equipped with a positioning jumper 3, and the jumper 3 is aligned radially with the piston The inner diameter of the sleeve 4 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com