LED light for distribution box

A technology for LED lamps and distribution boxes, which is applied in the direction of electric light source, damage prevention measures for lighting devices, lighting and heating equipment, etc. problems, to achieve the effect of reducing the probability of damage, not easy to break, and low permanent deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the transparent plate sheet is:

[0033] (1) According to the formula ratio, add the raw materials into the kneader and mix evenly, and knead at a temperature of 95-120°C for 8-20 minutes;

[0034] (2) Then discharge the kneaded mixture, stir and cool to 35-40°C;

[0035] (3) adding the material into the granulator for twin-screw extrusion and granulation, the temperature of the screw extruder is 120-180°C;

[0036] (4) Then add the extruder to extrude the sheet. The barrel temperature of the extruder is 150-190°C, and then enter the pressure roller to extrude the material. The temperature of the pressure roller is controlled at 50-80°C. Cool and form to obtain a sheet of a light-transmitting plate.

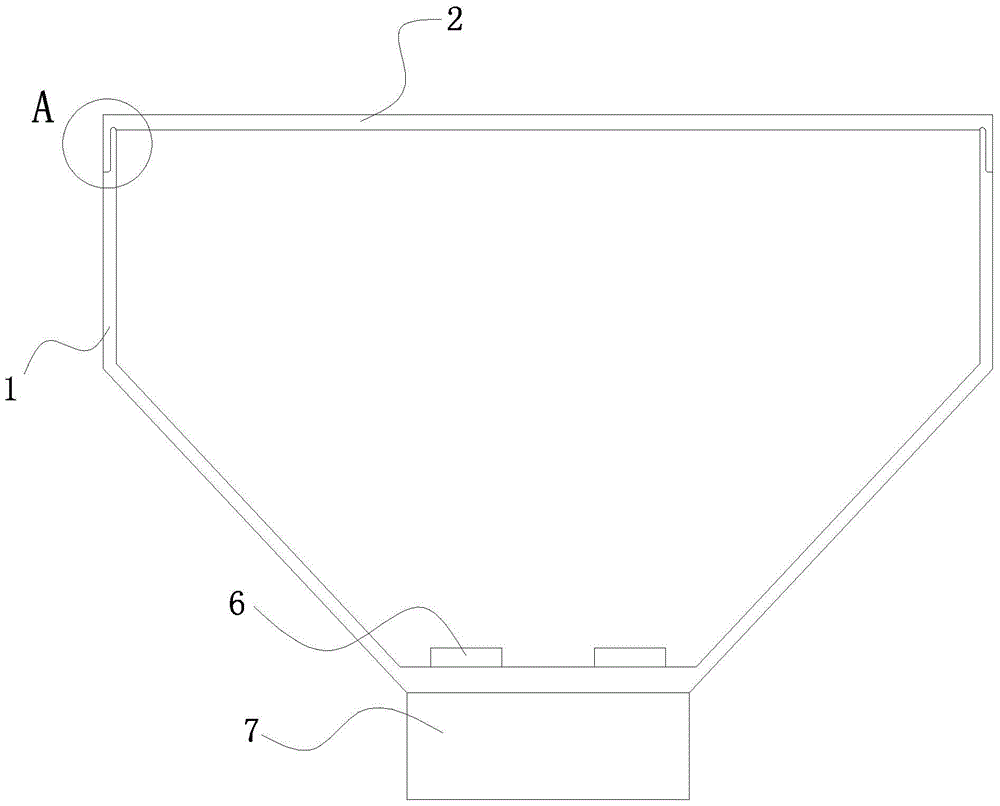

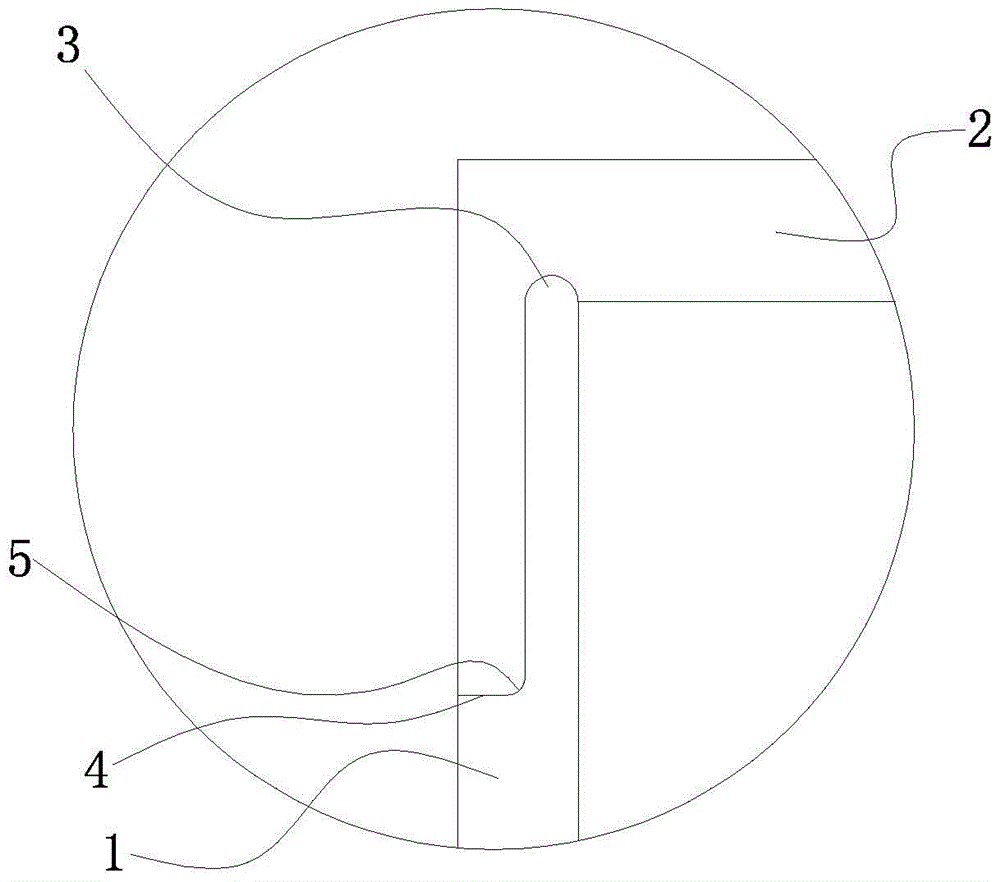

[0037] The end surface 3 is a semi-arc convex surface, and the light-transmitting plate 2 is provided with a semi-arc concave surface matched with the semi-arc convex surface.

[0038] The outer surface is provided with an annular stepped surfa...

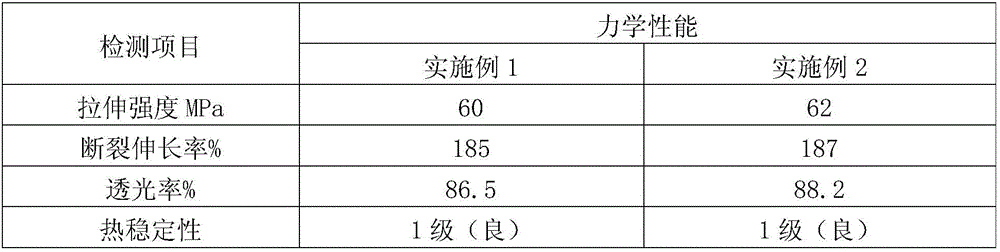

Embodiment 1

[0042] Light-transmitting plate material composition: 100 parts of polyvinyl chloride resin (YH-2500 polyvinyl chloride resin: S-700 polyvinyl chloride resin = 8:1), 2 parts of stabilizer (CZ-001 stabilizer), lubricant (GH -104) 0.5 parts, coloring agent (ultramarine powder) 0.001 parts, impact modifier (MBS) 3 parts, dioctyl phthalate 3 parts.

[0043] The preparation method of the above-mentioned light-transmitting plate sheet of the present invention is:

[0044] 1 According to the proportion of the formula, add the raw materials into the kneader and mix evenly, and knead for 8-20min at a temperature of 95-120°C;

[0045]2 Then discharge the kneaded mixture, stir and cool to 35-40°C;

[0046] 3. Put the material into the granulator for twin-screw extrusion and granulation. The temperature of the screw extruder is 120-180°C;

[0047] 4 Then add the extruder to extrude the sheet. The barrel temperature of the extruder is 150-190°C, and then enter the pressure roller to extr...

Embodiment 2

[0049] Polyvinyl chloride resin (YH-2500 polyvinyl chloride resin: S-700 polyvinyl chloride resin = 10:1) 100 parts, stabilizer (TM-181 type) 3 parts, lubricant (GH-104) 1 part, coloring Agent (ultramarine powder) 0.0015 parts, impact modifier (MBS) 4 parts, dioctyl phthalate 4 parts.

[0050] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com