Method for detecting calcium carbonate residue after cleaning of calcium preparation production line

An inspection method and production line technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of inability to issue accurate data, difficulty in trace analysis and detection, etc., and achieve the effects of accurate data, high sensitivity, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

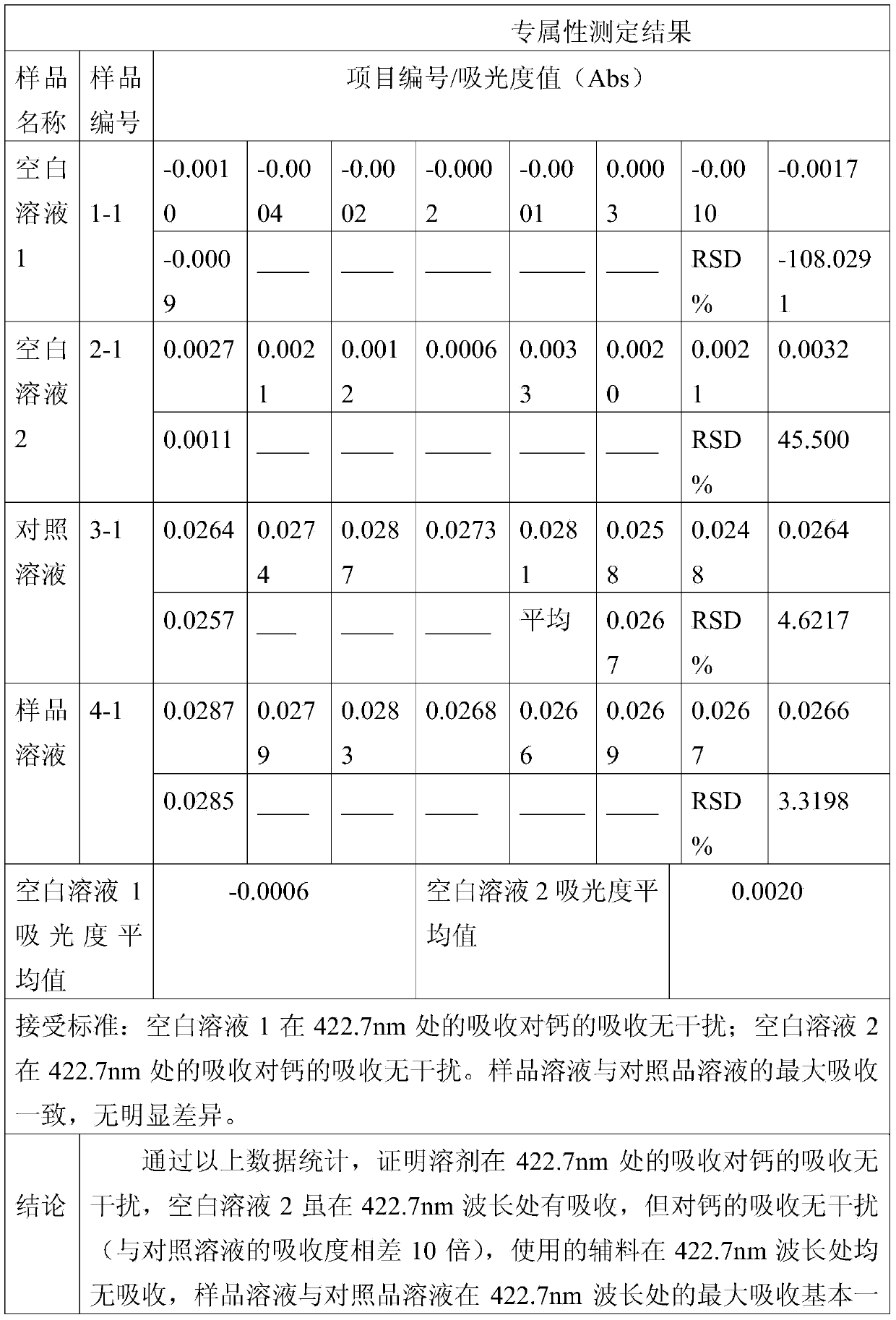

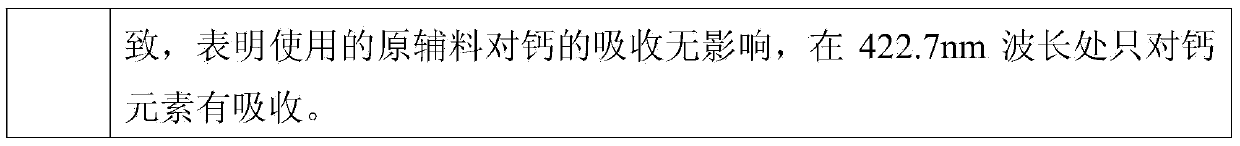

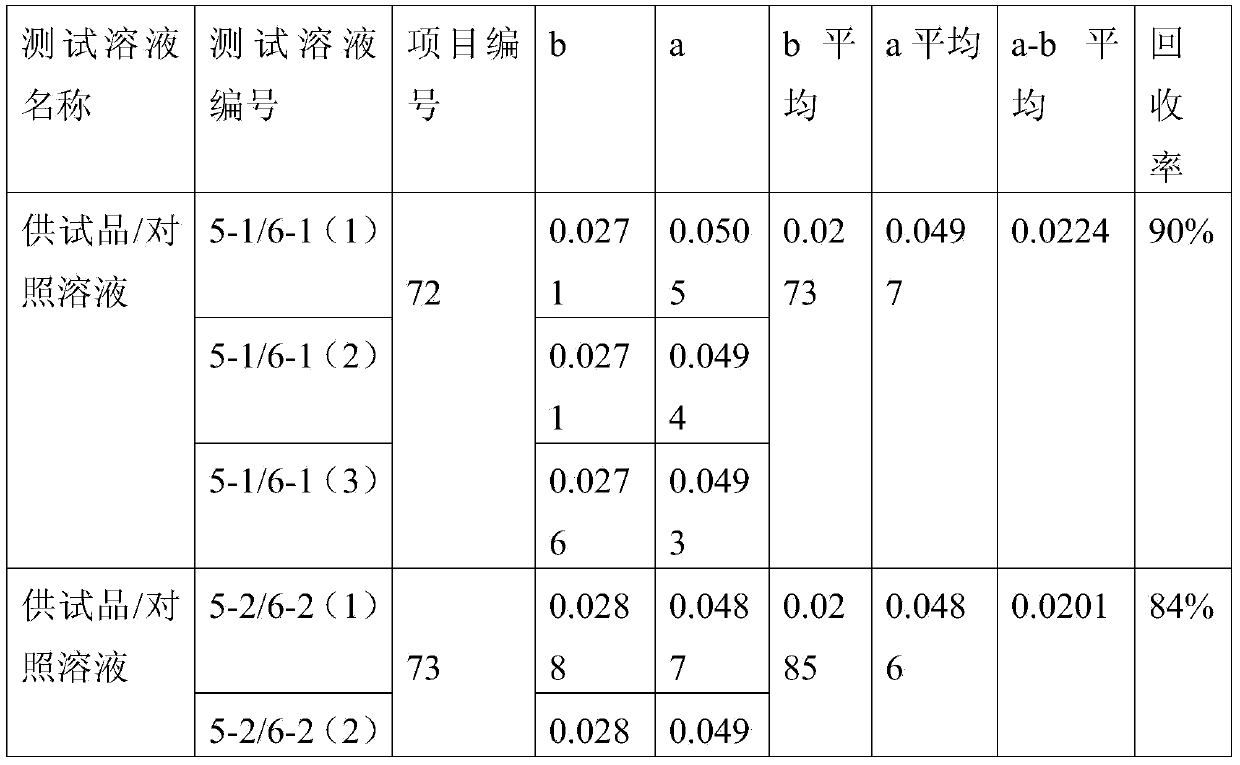

Examples

Embodiment Construction

[0024] The calcium carbonate residual inspection method after the calcium preparation production line of the present invention is cleaned, comprises the following steps:

[0025] (1) Take 5 cotton swabs, wet them with the wiping solution, and press the cotton swabs on the wall of the cup to make the cotton swabs free of water droplets and suitable for dry humidity; then wipe the surface of the equipment respectively;

[0026] The wiping solution was 8 wt% hydrochloric acid or purified water. The method of wiping the surface of the device with the cotton swab is as follows: horizontal detour wiping and vertical detour wiping are performed alternately, and at least 5 times of wiping. The sampling area of each swab is 200cm 2 .

[0027] (2) Put the wiped cotton swab in a 20ml beaker, add 20ml of 8wt% hydrochloric acid and soak for about 10 minutes; after 2 minutes of ultrasonication, transfer the solution to the first 50ml measuring bottle, and repeat the above operation with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com