Method for determining photoetching process window online

A lithography process and technology, applied in microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems of inability to accurately judge the size of the difference, increase time and cost, and consume labor, so as to shorten the judgment and adjustment cycle. , Improve the quality and reduce the effect of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Attached below Figure 2-4 , the specific embodiment of the present invention will be further described in detail.

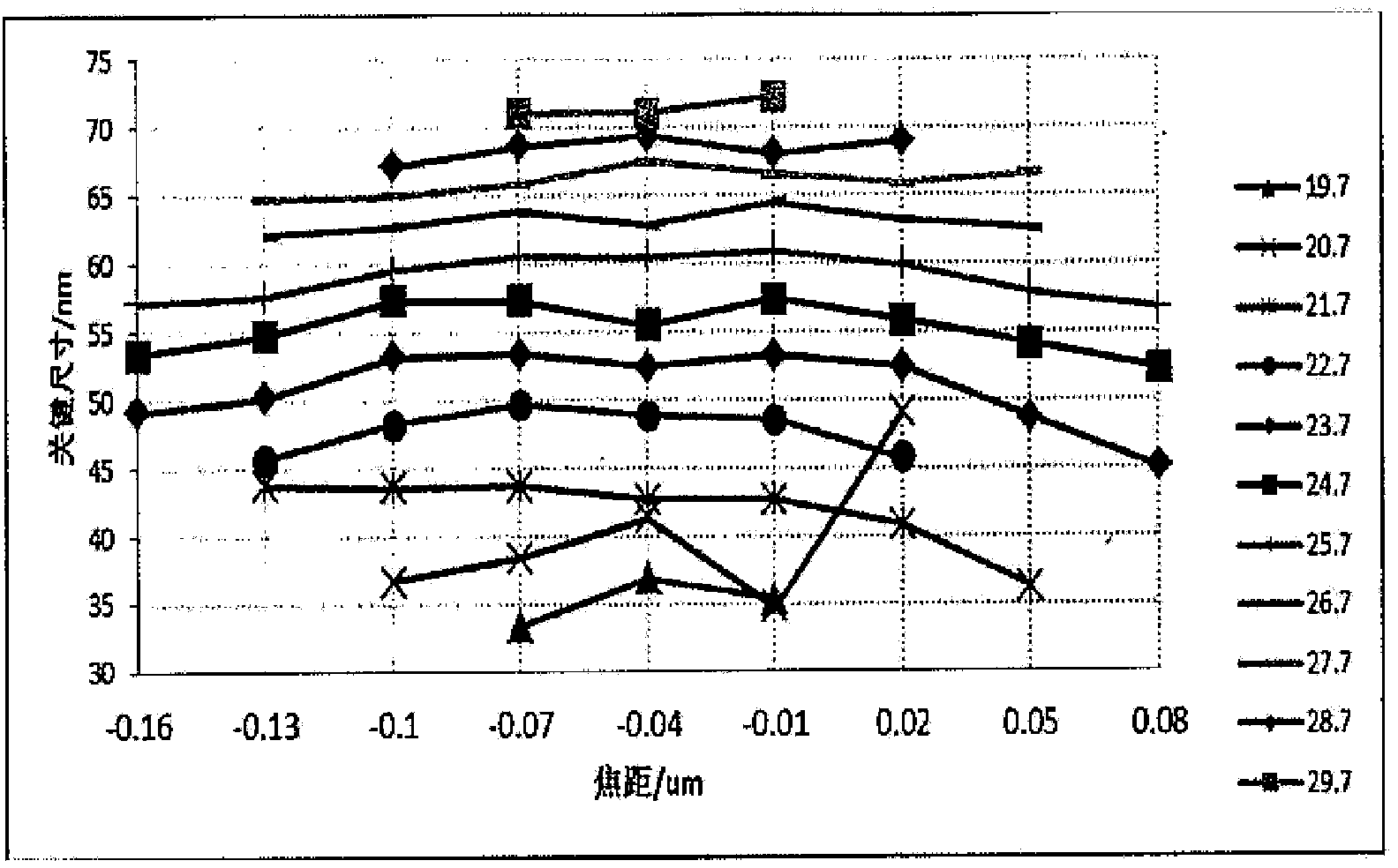

[0036] It should be noted that in the following embodiments, the target critical dimension is 55nm and the specification is + / -6nm as an example.

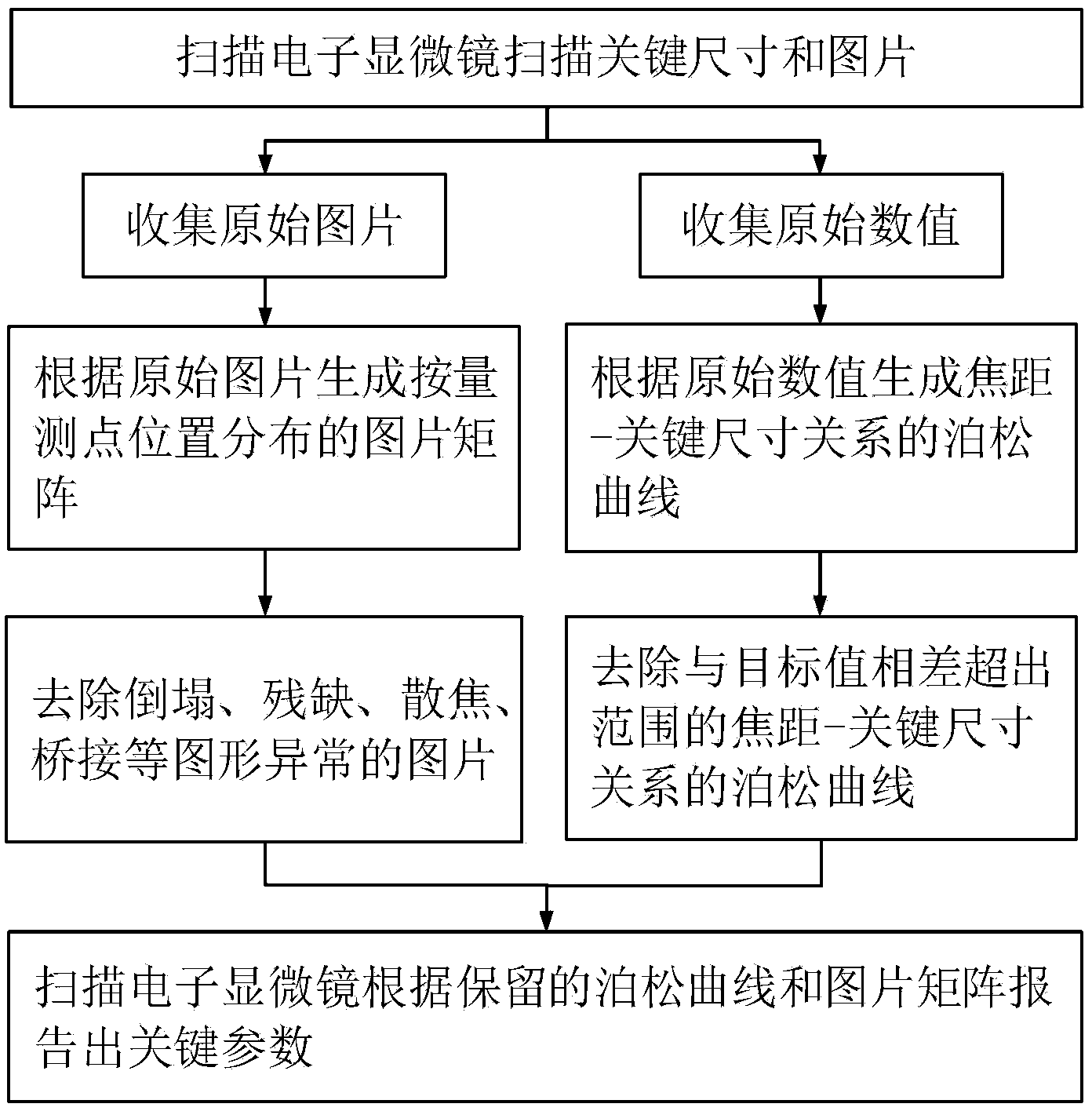

[0037] see figure 2 , figure 2 It is a logical control block diagram for scanning a wafer with a scanning electron microscope and performing data processing in the present invention; it illustrates a method for determining the photolithography process window on-line, including the following steps:

[0038] Step S1: Please refer to Table 1. Table 1 is the focal length-energy matrix collected by a scanning electron microscope. The target critical dimension is 55nm, and the specification is + / -6nm. As shown in Table 1, the first row of the matrix is energy, and the unit is mj / cm 2 , increasing 1mj / cm for each cell from left to right 2 ;The first column of the matrix is the focal length, the unit is um,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com