Precision machine tool mass matching design method based on response surface and genetic algorithm

A technology of precision machine tools and genetic algorithm, applied in the field of quality matching design of precision machine tools based on response surface and genetic algorithm, can solve the problems of difficult to ensure optimal parameters, consume a lot of time, can not meet production requirements, etc., to improve machining accuracy and processing efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the content, features and effects of the present invention, the technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

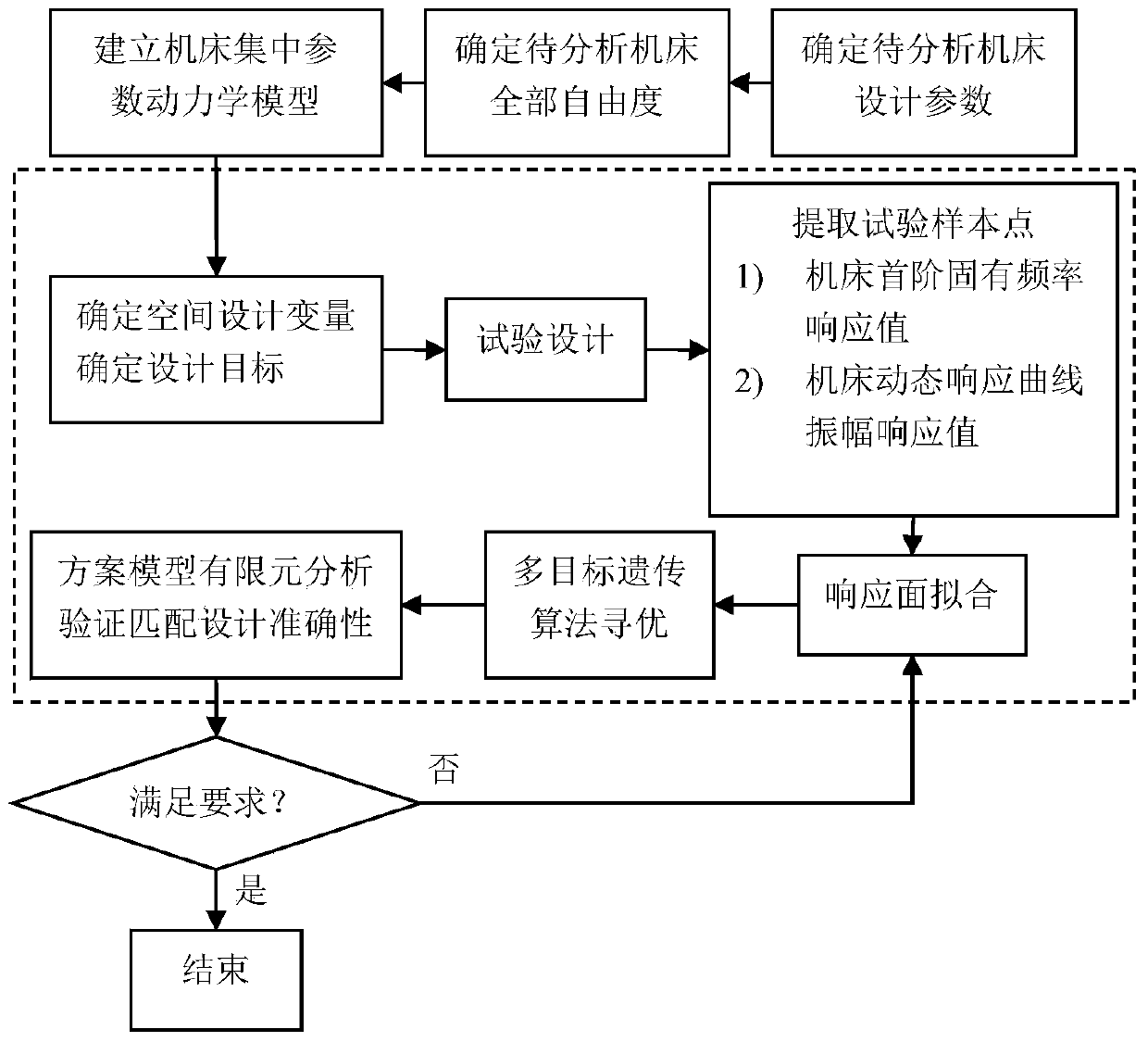

[0028] Such as figure 1 Shown is the flow chart of the present invention.

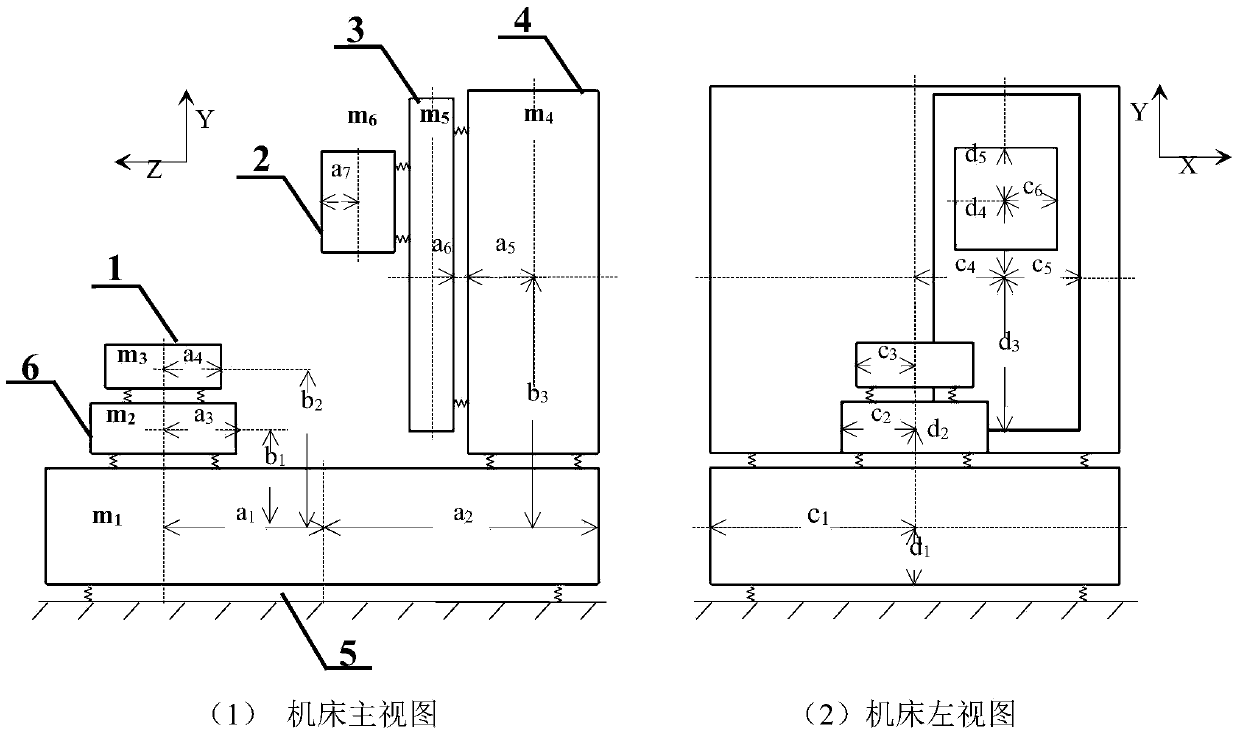

[0029] Step 1: Determine the parameters required for the precision machine tool to be analyzed

[0030] The parameters required by the machine tool to be analyzed are the external dimensions of the supporting large part, the machining space of the machine tool, the X, Y, Z three-way travel of the machine tool, and the parameters of the joint surface, excluding complex internal designs such as the wall thickness planning of the large part and the layout of ribs . The required geometric parameters of the machine tool to be analyzed are as follows: figure 2 As shown, among them, the overall dimension of the bed a 2 、c 1 、d 1 , the overall dimension of the sliding table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com