Vehicle-mounted battery pack heat management system

A technology of thermal management system and battery pack, applied in the field of thermal management system, can solve problems such as difficult to achieve expected effect, discount of thermal management effect, unfavorable air flow, etc., achieve excellent heat dissipation, increase heat exchange efficiency, and facilitate implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

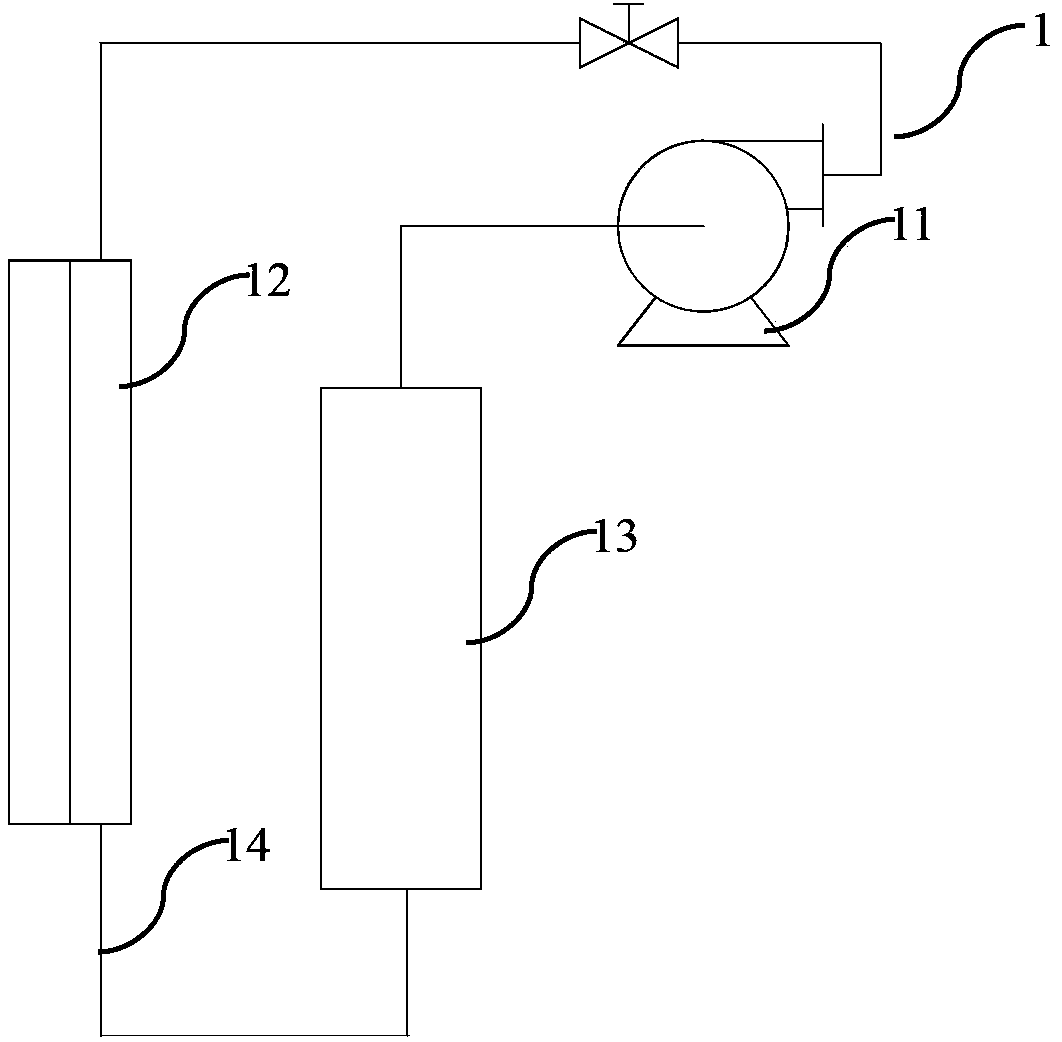

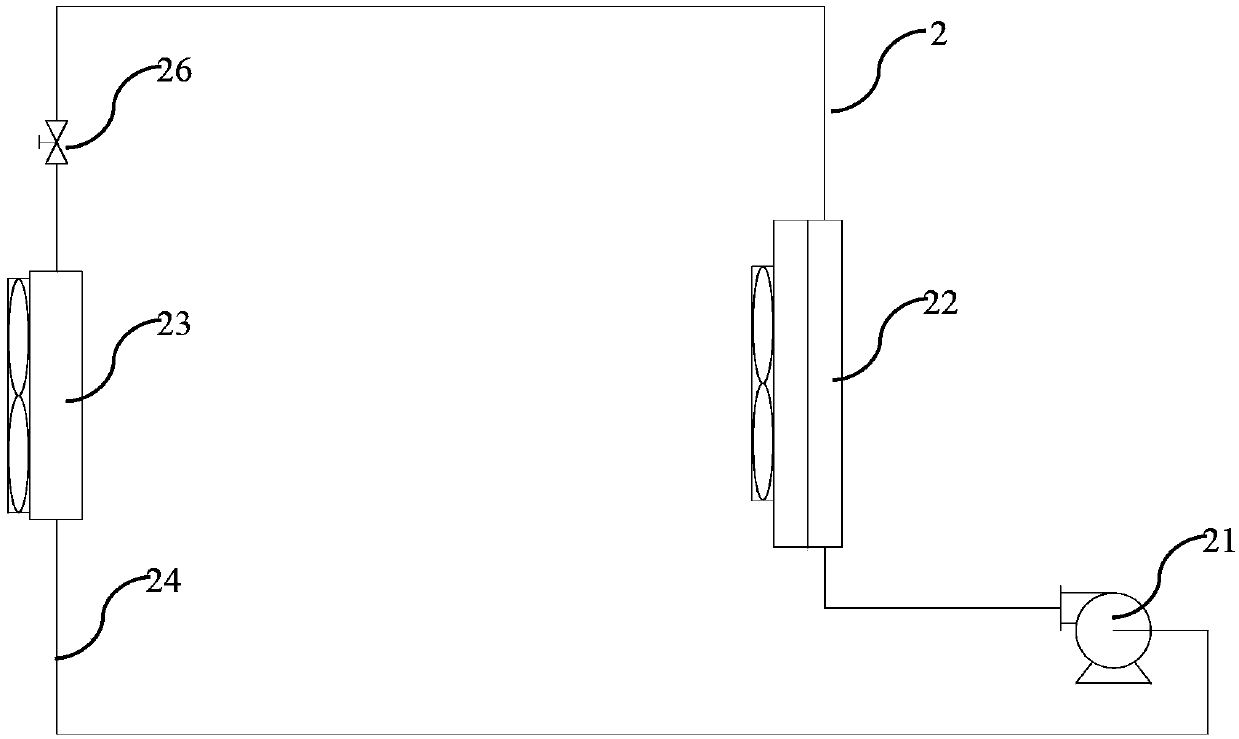

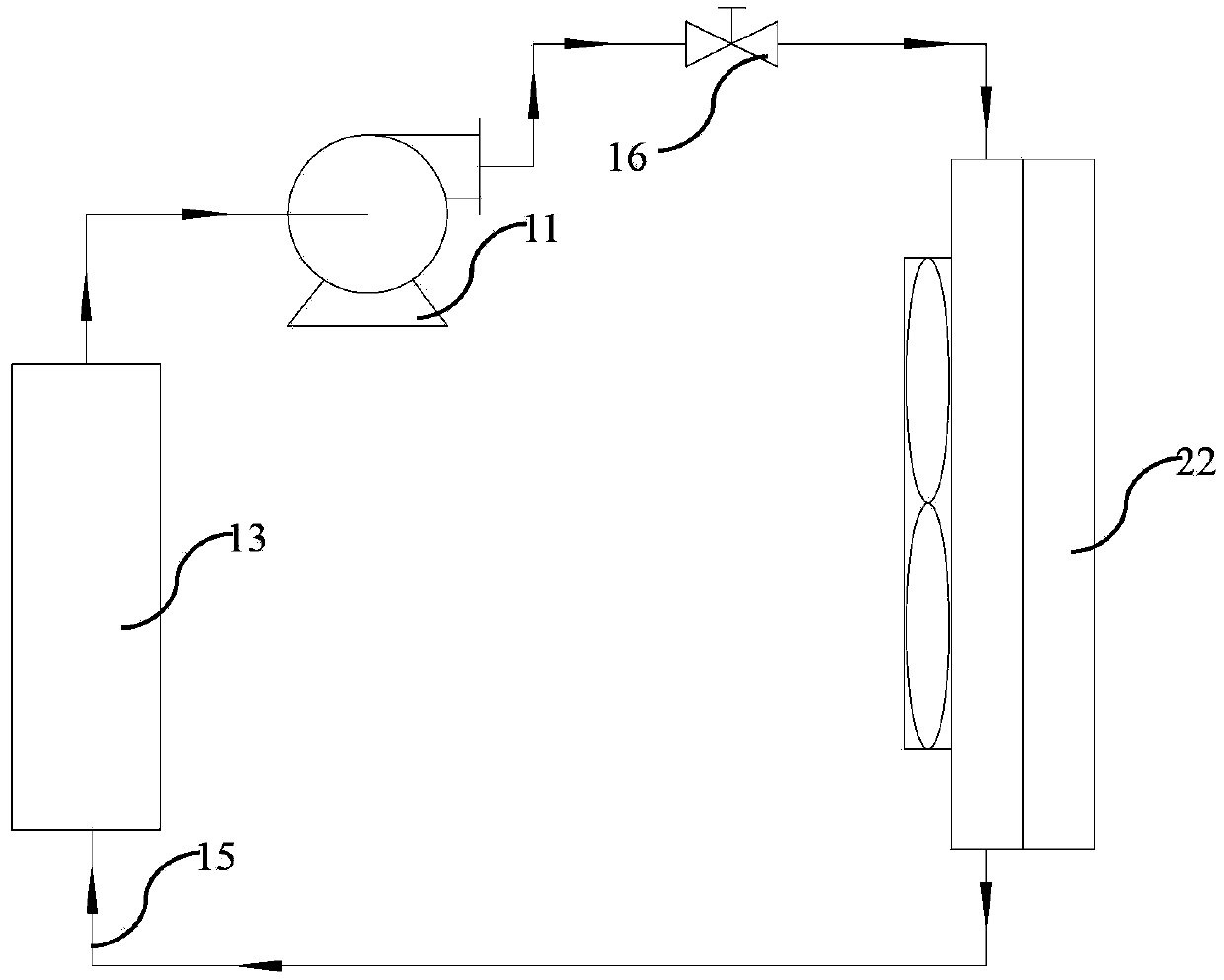

[0039] Such as Figure 1-Figure 4 As shown, the invention provides a thermal management system for a vehicle-mounted battery pack, including a battery heat exchange system 1 and an air conditioner heat exchange system 2. The battery heat exchange system 1 includes a circulating pump 11, a heat exchanger 12, a battery pack 13, and a battery The group 13, the circulation pump 11 and the heat exchanger 12 are connected through the circulation pipeline 14 of the battery heat exchange system containing the heat exchange fluid inside, and a switch valve for controlling the on-off of the pipeline is set between the circulation pump 11 and the heat exchanger 12, and the air conditioner The heat exchange system 2 includes a compressor 21, a radiator A22, and a radiator B23, and the compressor 21, the radiator A22, and the radiator B23 are connected through an air-conditioning heat exchange system circulation pipeline 24 containing an air-conditioning refrigerant inside; the battery pack...

Embodiment 2

[0043] Such as Figure 1-Figure 4 As shown, the invention provides a thermal management system for a vehicle-mounted battery pack, including a battery heat exchange system 1 and an air conditioner heat exchange system 2. The battery heat exchange system 1 includes a circulating pump 11, a heat exchanger 12, a battery pack 13, and a battery The group 13, the circulation pump 11 and the heat exchanger 12 are connected through the circulation pipeline 14 of the battery heat exchange system containing the heat exchange fluid inside, and a switch valve for controlling the on-off of the pipeline is set between the circulation pump 11 and the heat exchanger 12, and the air conditioner The heat exchange system 2 includes a compressor 21, radiator A22, and radiator B23, and the compressor 21, radiator A22, and radiator B23 are connected through an air-conditioning heat exchange system circulation pipeline 24 containing air-conditioning refrigerant inside. The battery heat exchange syste...

Embodiment 3

[0048] Such as Figure 1-Figure 4 As shown, the invention provides a thermal management system for a vehicle-mounted battery pack, including a battery heat exchange system 1 and an air conditioner heat exchange system 2. The battery heat exchange system 1 includes a circulating pump 11, a heat exchanger 12, a battery pack 13, and a battery The group 13, the circulation pump 11 and the heat exchanger 12 are connected through the circulation pipeline 14 of the battery heat exchange system containing the heat exchange fluid inside, and a switch valve for controlling the on-off of the pipeline is set between the circulation pump 11 and the heat exchanger 12, and the air conditioner The heat exchange system 2 includes a compressor 21, radiator A22, and radiator B23, and the compressor 21, radiator A22, and radiator B23 are connected through an air-conditioning heat exchange system circulation pipeline 24 containing air-conditioning refrigerant inside. The battery heat exchange syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com