Fiber structure intended to reinforce composite material parts and including a portion having a reduced thickness

A fiber structure and composite material technology, applied in the field of reinforced fiber structure, can solve problems such as fiber density change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention is generally applied to the manufacture of fibrous structures suitable for the construction of fibrous reinforcements, called preforms, used in the manufacture of composite material components, in particular aeroengine blades, obtained by densifying the fibrous structure with a matrix. Typically, the matrix is manufactured from resins for composites, using composites to relatively low temperatures, typically up to 300°C, or by refractory materials such as carbon or ceramics for thermal structural composites.

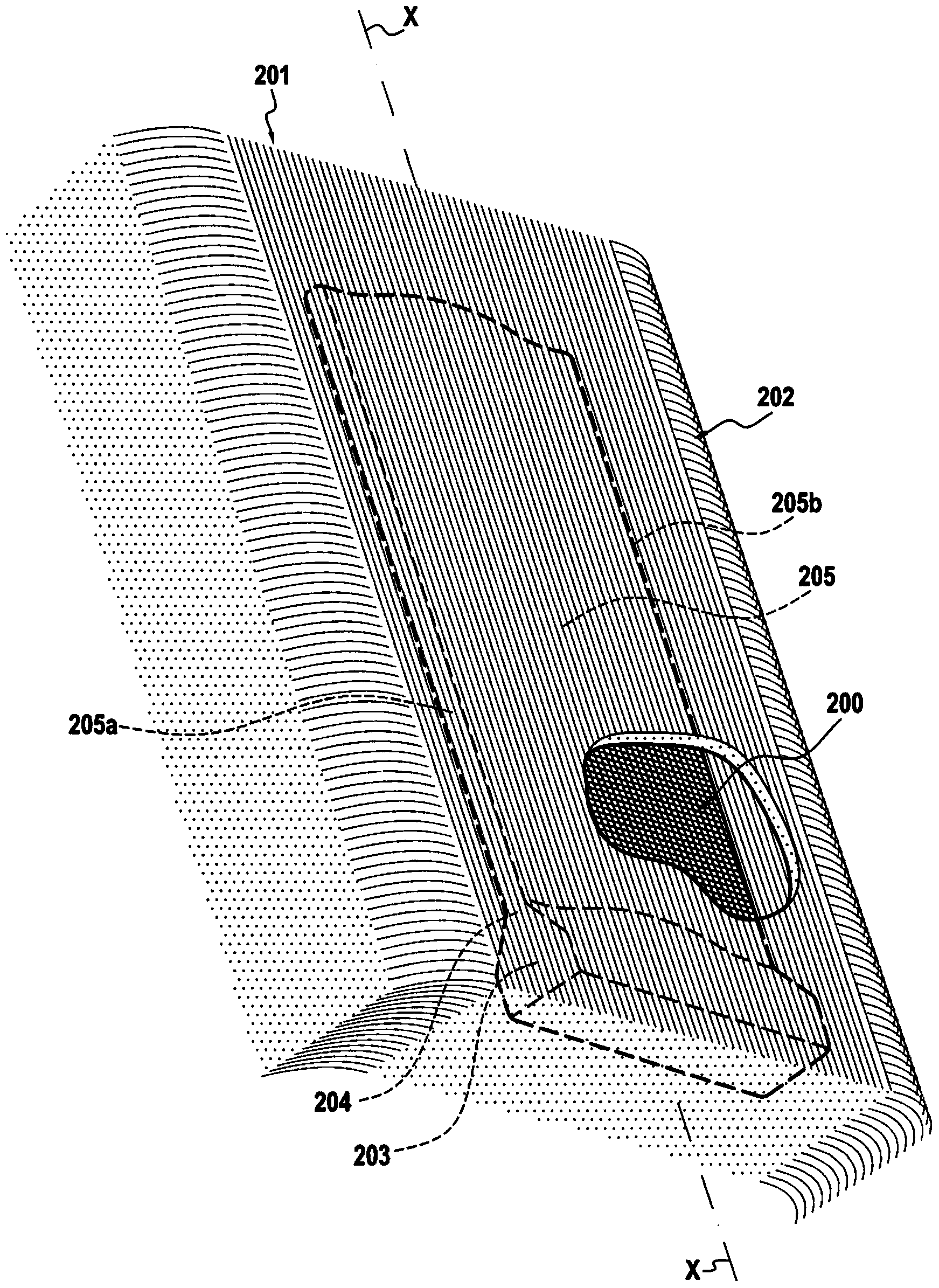

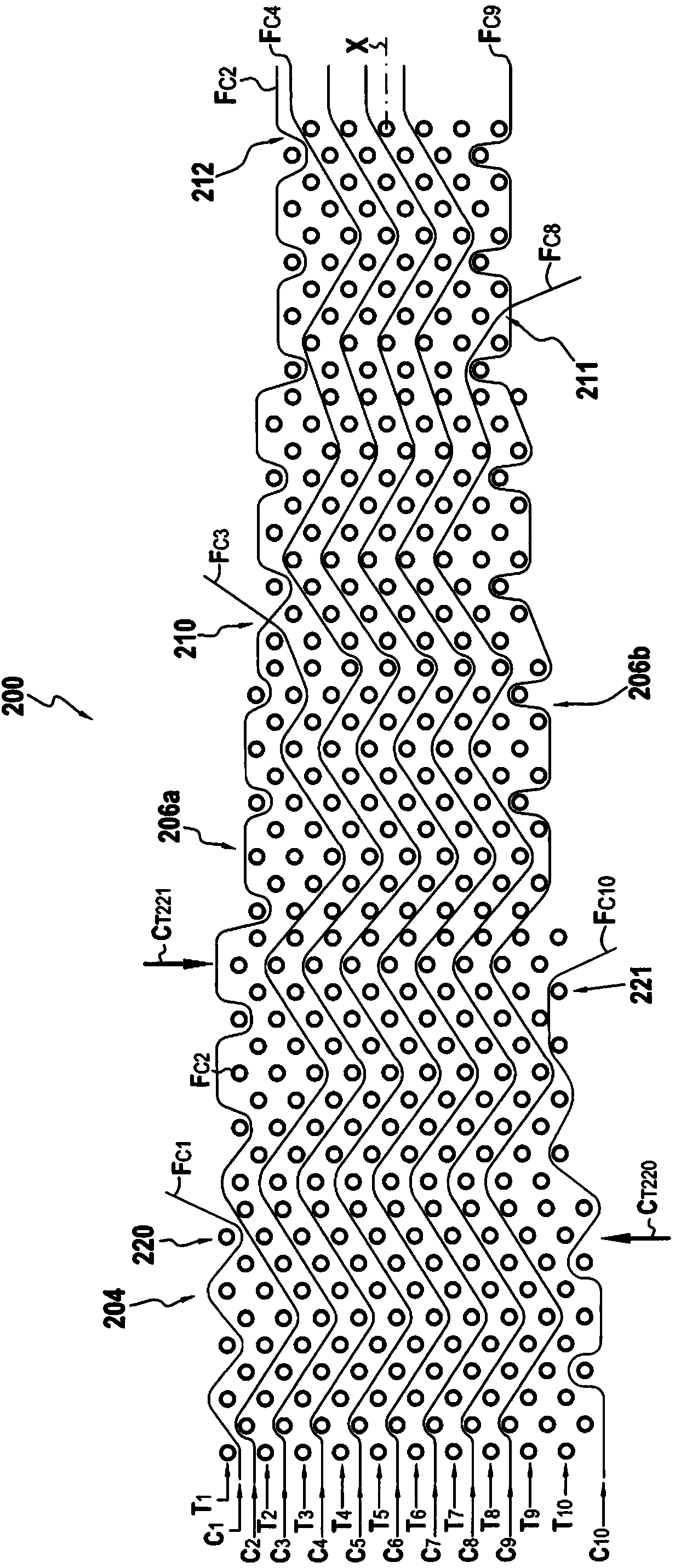

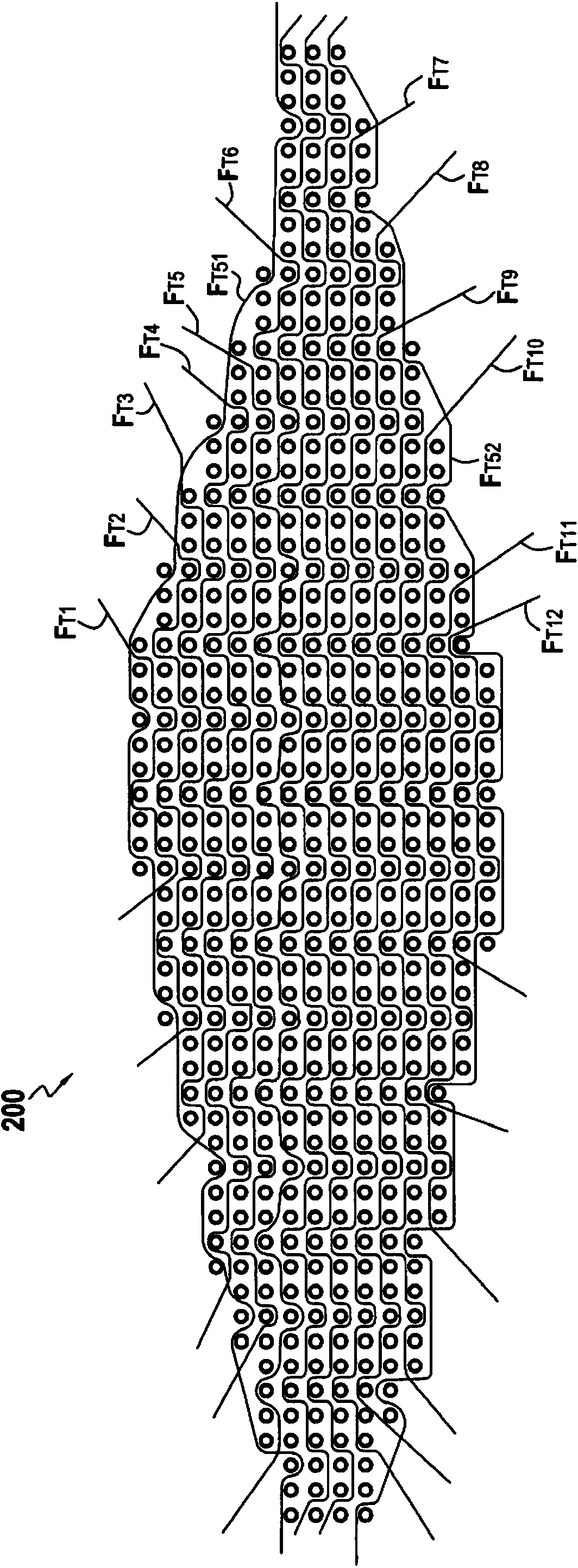

[0035] FIG. 1 is a detailed schematic illustration of a fiber-reinforced fiber structure 200 for forming an aeroengine blade.

[0036] The fibrous structure 200 is obtained by multilayer weaving, which is carried out in a known manner using a Jacquard type loom having a bundle or strand of warp yarns 201 organized in multiple layers, the warp yarns It is interlocked with the weft yarn 202 which is also arranged in multiple layers. Examples of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com