Processing method of precooked coarse grains simultaneously boiled and cooked with rice

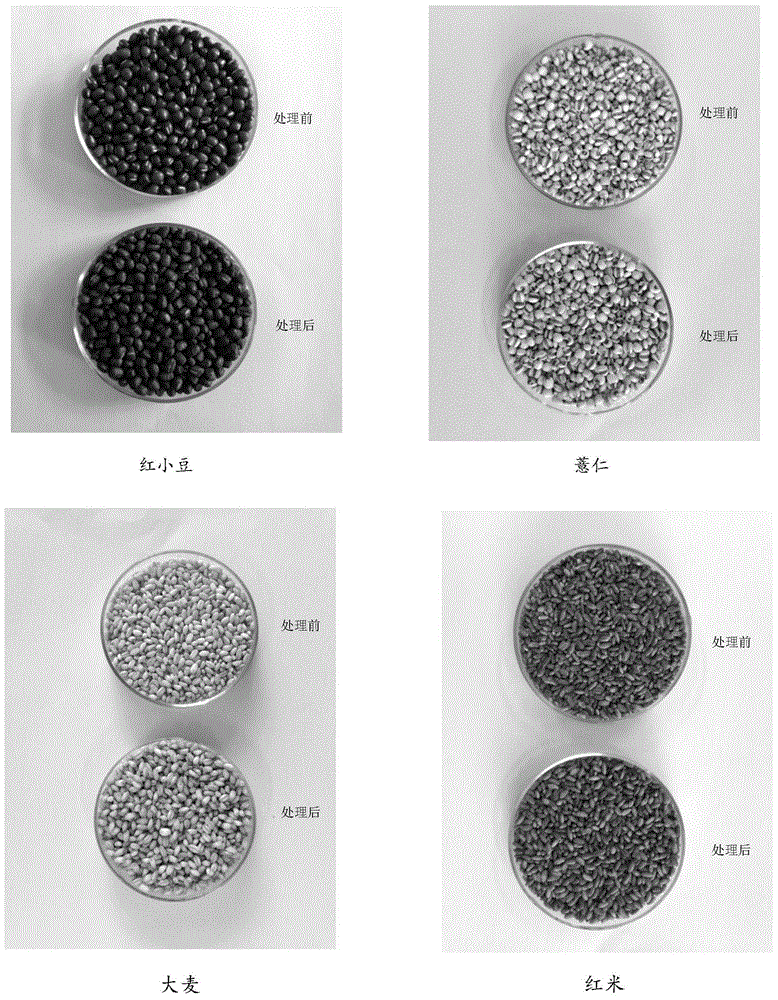

A technology that cooks and cooks miscellaneous grains at the same time. It is applied in the fields of application, food preparation, food science, etc. It can solve the problems of changes in product appearance and edible characteristics, unfavorable storage and transportation of products, loss of nutrients in products, etc., so as to save soaking time. , The effect of maintaining appearance, taste and odor, and less loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

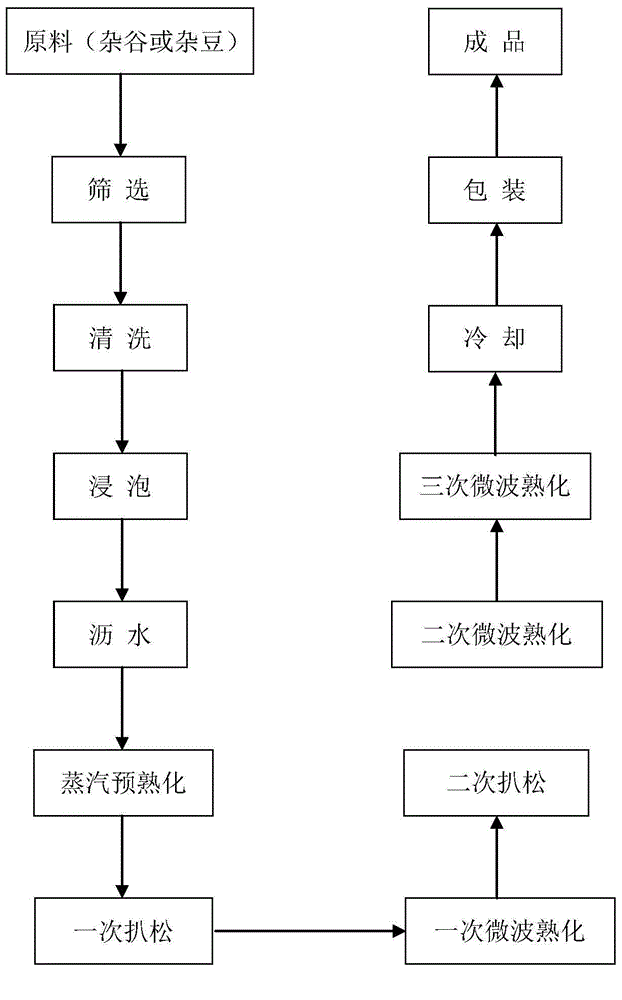

Method used

Image

Examples

Embodiment 1

[0047] A method for processing pre-cooked miscellaneous grains with red beans as raw materials, which is boiled and cooked together with rice, and the specific steps are as follows:

[0048] 1) Screening of adzuki bean: select high-quality adzuki bean, remove gravel, clods, heterogeneous grains, insect-eaten grains, imperfect grains, damaged grains and spotted grains from raw materials to obtain screening raw materials;

[0049] 2) Cleaning: Wash the red bean obtained in step 1) for 2-3 times with tap water, or use an automatic washing machine for miscellaneous grains, and then rinse with pure water once to obtain washed red bean;

[0050] 3) Soaking: soak the cleaned red beans obtained in step 2) with pure water, the soaking temperature is 25°C, the soaking time is 15 hours, the ratio of soaked red beans to water is 1:6, and the water content of the soaked red beans is controlled at 45 %, the pretreated red bean is obtained after draining;

[0051] 4) Steam pre-curing: put t...

Embodiment 2

[0061] A method for processing pre-cooked miscellaneous grains using black beans as raw materials and cooked together with rice, the specific steps are as follows:

[0062] 1) Screening of black soybeans: select high-quality black soybeans, remove gravel, soil clods, heterogeneous grains, insect-eaten grains, imperfect grains, damaged grains and spotted grains from the raw materials to obtain screening raw materials;

[0063] 2) Cleaning: Wash the screened black beans obtained in step 1) for 2-3 times with tap water, or use an automatic cleaning machine for miscellaneous grains, and then rinse with pure water once to obtain cleaned black beans;

[0064] 3) Soaking: Soak the cleaned black beans obtained in step 2) with pure water, the soaking temperature is 30°C, the soaking time is 6 hours, the ratio of soaked black beans to water is 1:4, the water content of the soaked black beans is controlled at 40%, and drained Obtain the pretreatment black soybean afterward;

[0065] 4) ...

Embodiment 3

[0075] A method for processing pre-cooked miscellaneous grains with barley as a raw material and cooked together with rice, the specific steps are as follows:

[0076] 1) Screening of barley: select high-quality barley, remove gravel, soil clods, foreign seeds, insect-eaten seeds, imperfect kernels, damaged kernels and spotted kernels from the raw materials to obtain screened barley;

[0077] 2) Cleaning: Wash the barley obtained in step 1) for 2-3 times with tap water, or use an automatic washing machine for miscellaneous grains, and then rinse with pure water once to obtain the cleaned barley;

[0078] 3) Soaking: soak the cleaned barley obtained in step 2) with pure water, the soaking temperature is 40°C, the soaking time is 3 hours, the ratio of soaked barley to water is 1:3, the water content of the soaked barley is controlled at 40%, and drained Obtain pre-processed Job's tears afterwards;

[0079] 4) Steam pre-curing: put the pre-treated barley obtained in step 3) on a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com