Titanium alloy tinned wire drawing die and manufacturing method thereof

A wire drawing die, titanium alloy technology, applied in the direction of wire drawing die, metal wire drawing, metal processing equipment, etc., can solve the problems of unfavorable inlet bell mouth impurities, rapid discharge of impurities, metal wires are easy to absorb impurities, and reduce the service life of the mold. It is easy to solve Sinking, avoiding adhesion, and reducing the effect of pulling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

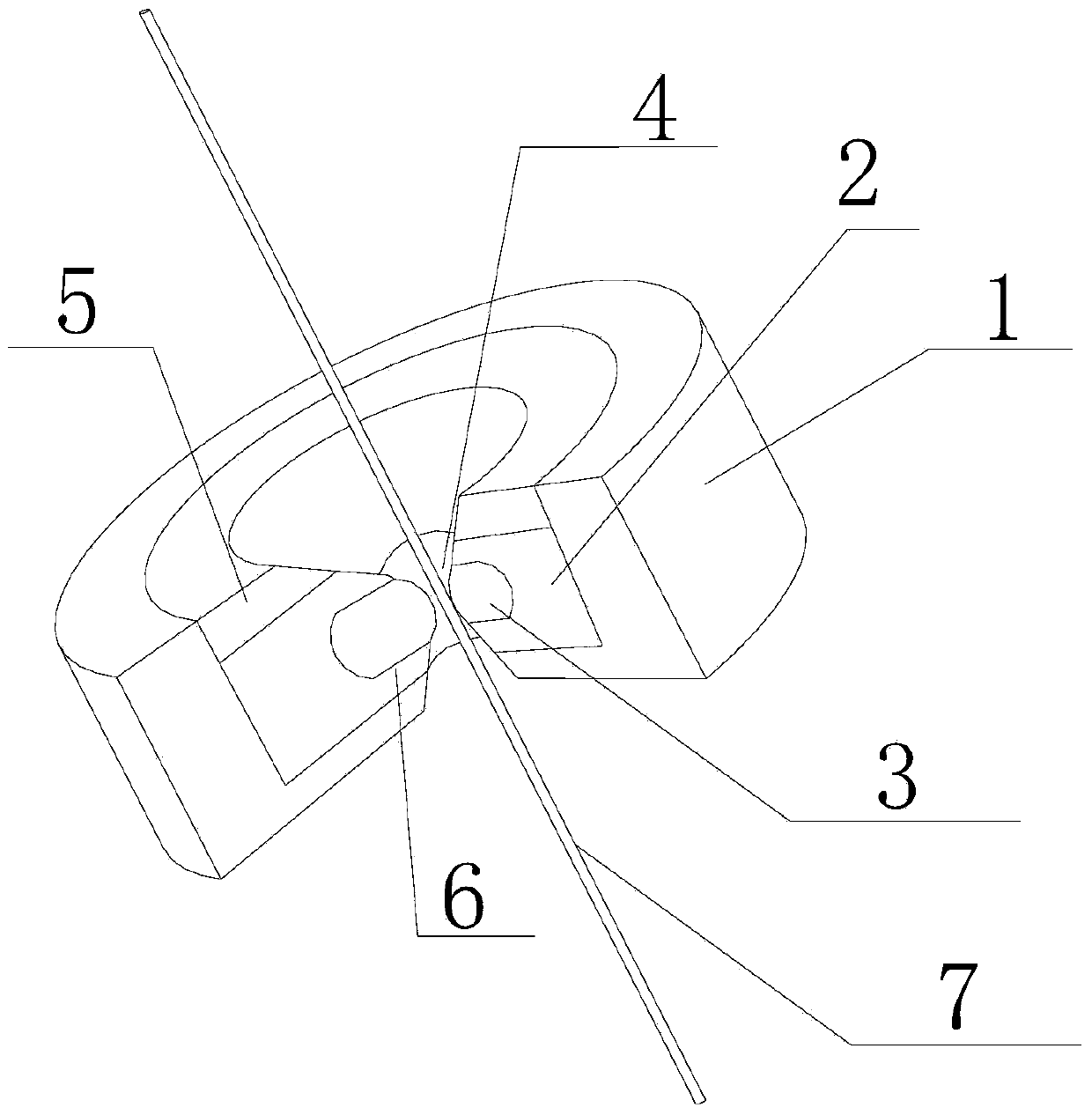

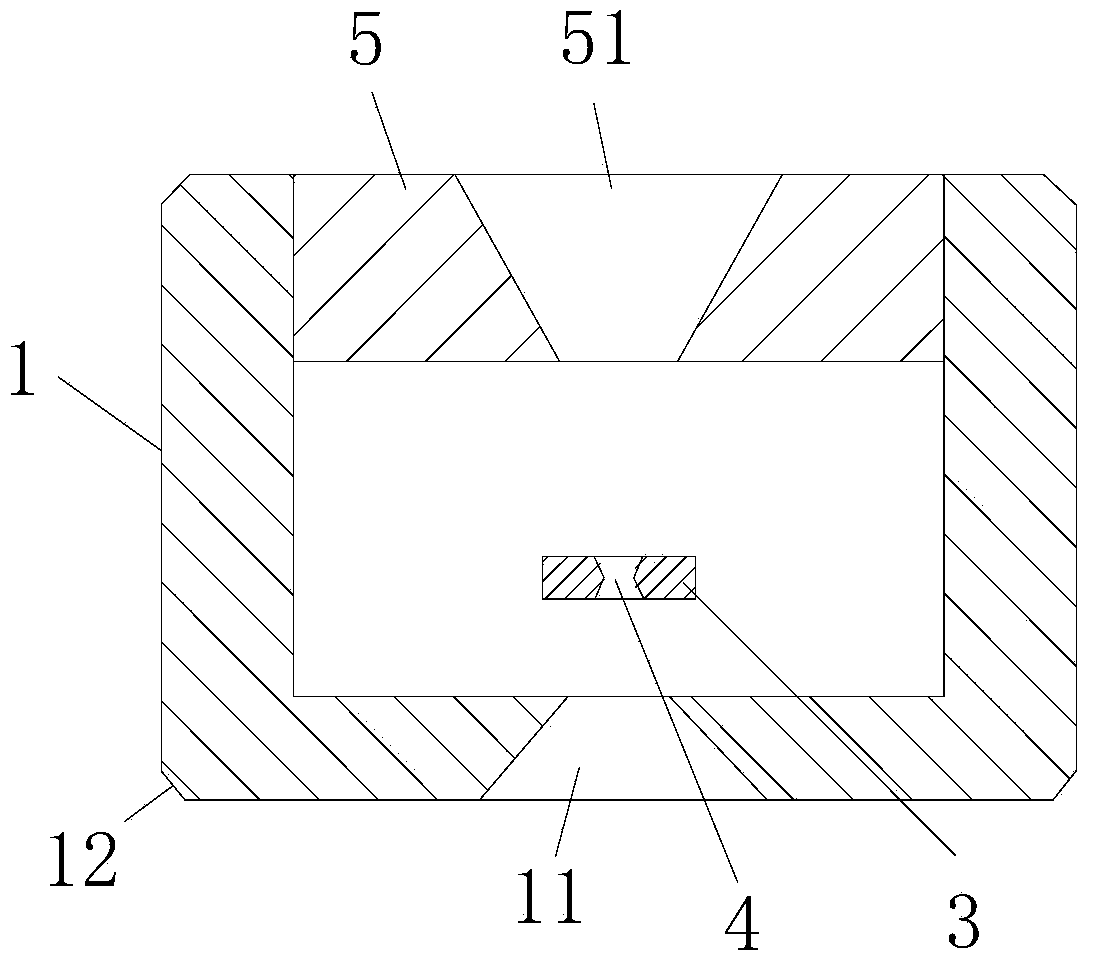

[0032] see figure 1 , figure 2 , a titanium alloy tin-plated wire drawing die provided in this embodiment includes a mold case 1 and a mold core embedded in the mold case 1, the mold core includes a metal sintered block 2, diamond particles 3 and a gland 5, and the mold case 1 is Titanium alloy mold cover 1, the mold cover 1 is a cylindrical cylinder with an upper end opening, and the outer circle of the mold cover 1 is provided with chamfers 12, so that it plays a positioning and guiding role on the mold base and can prevent bumps from hurting operators. The bottom center of the mold cover 1 is provided with an inlet tapered hole 11 with a small top and a large bottom as the inlet end of the wire drawing die. The angle of the inlet tapered hole 11 at the inlet end is an obtuse angle, preferably 120°. The metal sintered block 2 is placed in the mold On the bottom of the cover 1, the gland 5 is located on the top of the metal sintered block 2, and the center of the gland 5 is...

Embodiment 2

[0041] A preparation method of a titanium alloy tin-plated wire drawing die disclosed in this embodiment comprises the following steps:

[0042] (1) Prepare the titanium alloy mold cover 1 according to the set size;

[0043] (2) According to 82% of titanium, 10% of aluminum and 6% of nickel as the main components, the proportion of other auxiliary materials of 2% is equipped with mixed metal powder, put part of the mixed metal powder into the mold cover 1, cover the gland 5, and sinter After compacting at normal temperature on the press, take out the gland 5;

[0044] (3) A diamond particle 3 is bonded to the center of the compacted metal powder in the mold cover 1;

[0045] (4) Put the remaining mixed metal powder into the mold cover 1, cover the gland 5, and then put it into a sintering press for high-temperature sintering and compaction, and the mixed metal powder after high-temperature sintering and compaction forms a metal sintered block 2; The specific process is: heat...

Embodiment 3

[0048] This embodiment also discloses a method for preparing the aforementioned titanium alloy tin-plated wire drawing die, comprising the following steps:

[0049] (1) Prepare the titanium alloy mold cover 1 according to the set size;

[0050] (2) According to 81% of titanium, 9% of aluminum and 5% of nickel as the main components, the ratio of 5% of the remaining auxiliary materials is equipped with mixed metal powder, and part of the mixed metal powder is put into the mold cover 1, and the gland 5 is covered. After sintering After compacting at normal temperature on the press, take out the gland 5;

[0051] (3) A diamond particle 3 is bonded to the center of the compacted metal powder in the mold cover 1;

[0052] (4) Put the remaining mixed metal powder into the mold cover 1, cover the gland 5, and then put it into a sintering press for high-temperature sintering and compaction, and the mixed metal powder after high-temperature sintering and compaction forms a metal sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com