Upward punching die for case sideboard

A chassis and side plate technology, applied in the field of stamping processing, can solve the problems of poor blanking, high cost, and high defect rate, and achieve the effect of improving punching yield, avoiding scratches or scratches, and ensuring surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

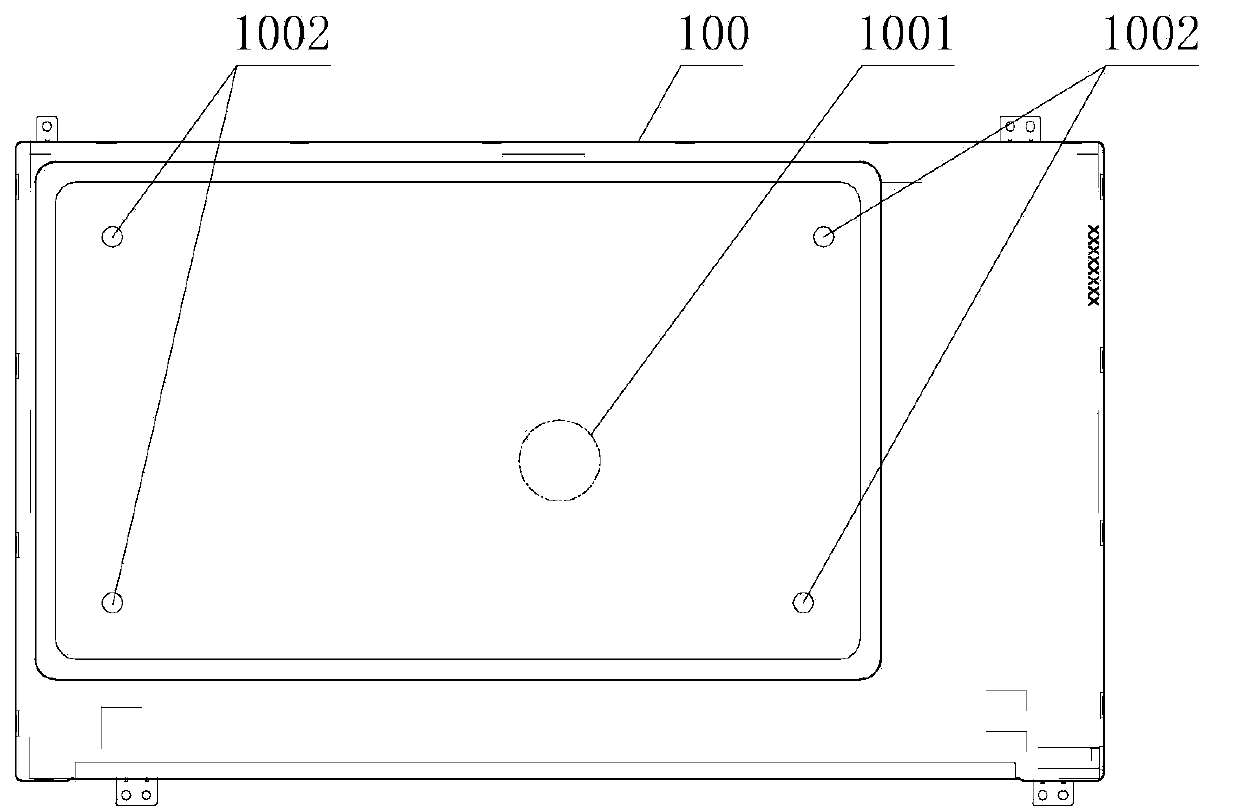

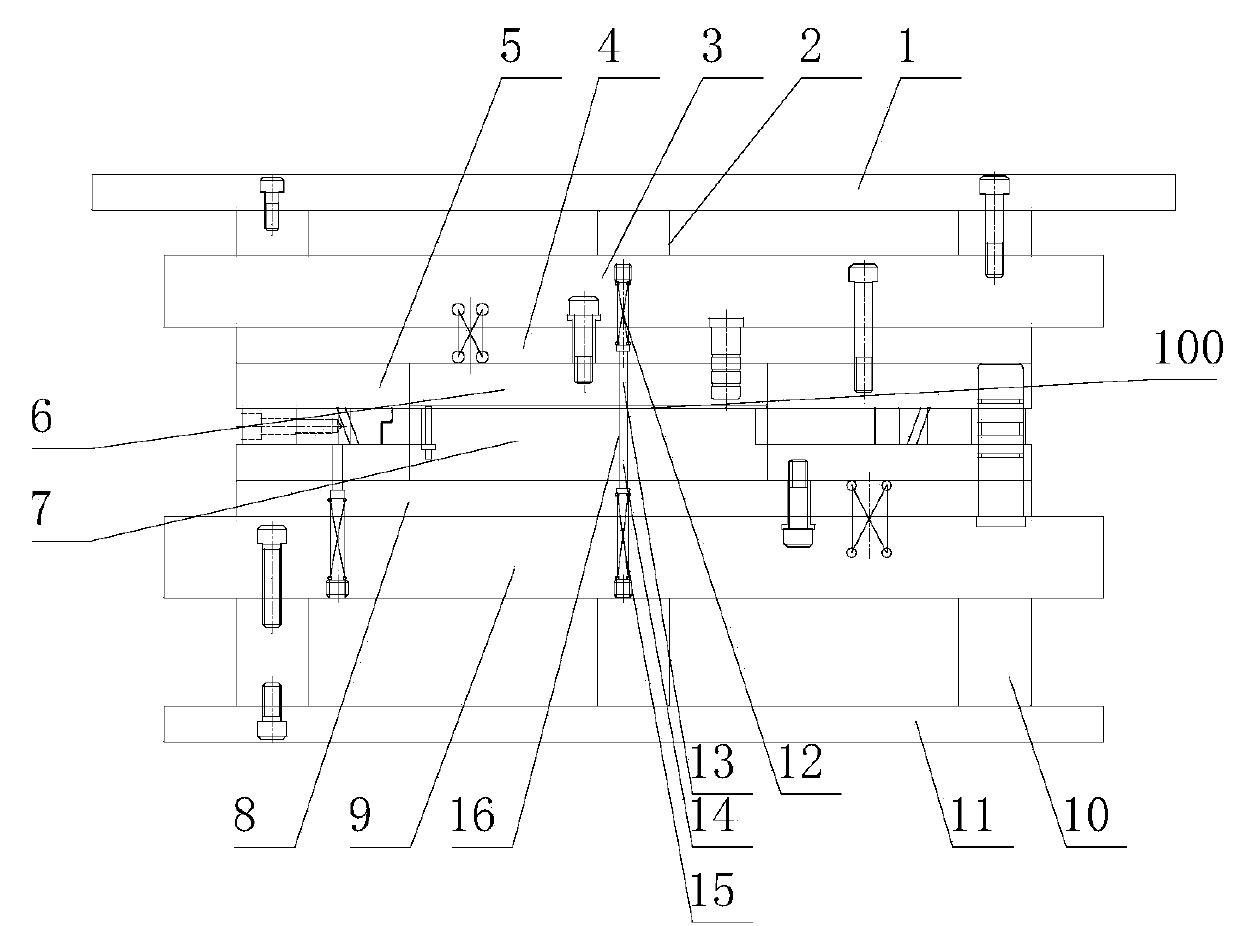

[0021] Such as figure 1 Shown is a schematic structural view of the chassis side plate to be processed in the present invention. In this embodiment, it is necessary to punch upward at the hole 1001 to be punched. Such as Figures 2 to 4 Shown is a structural schematic diagram of the upward punching die used for the side plate of the chassis of the present invention.

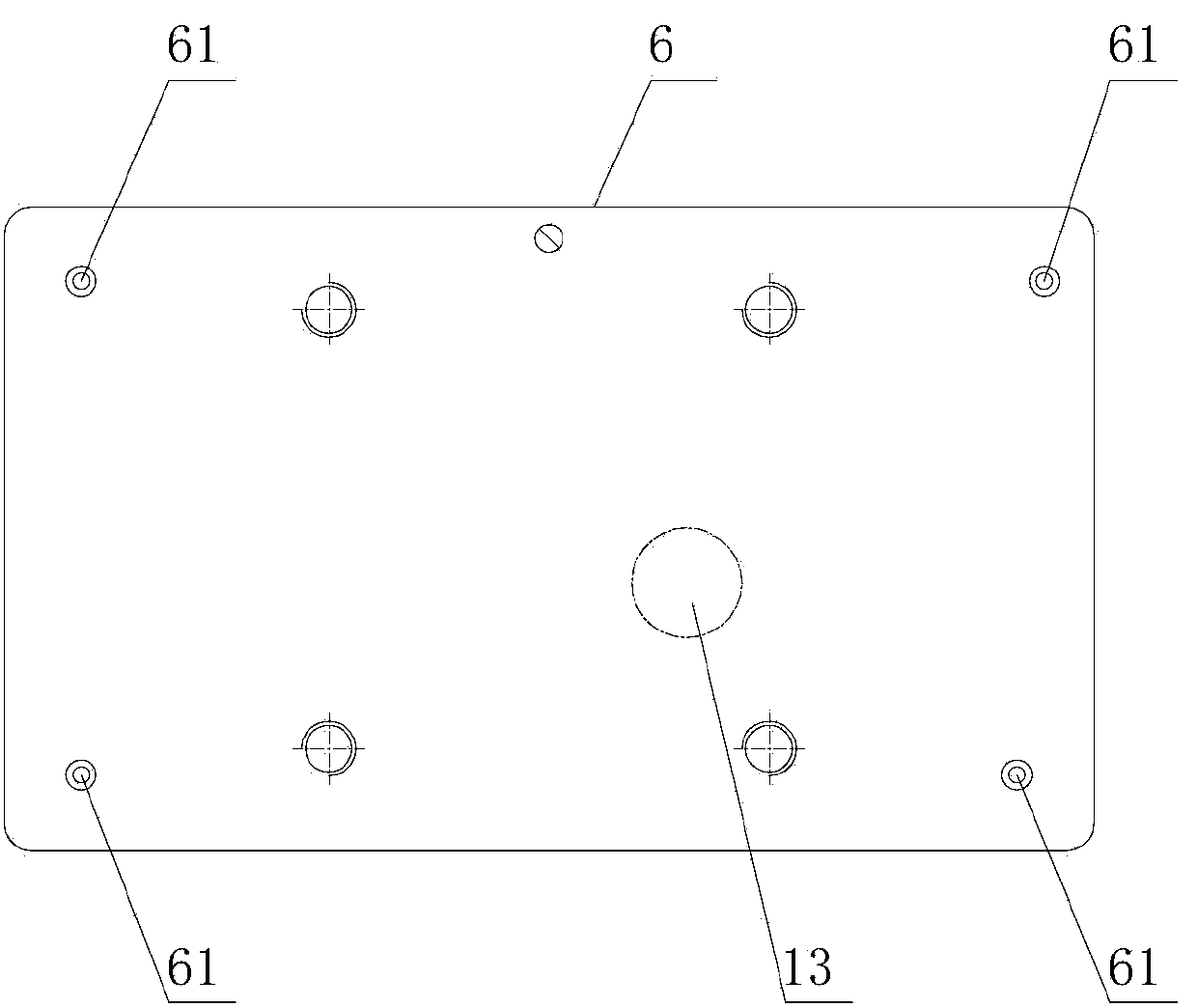

[0022] Specifically, an upward punching die for a side plate of a chassis includes an upper die and a lower die correspondingly arranged below the upper die, the upper die includes an upper die base 3, an upper clamping plate 4, an upper die base from top to bottom Template 5, upper mold base 3, upper splint 4 are connected with upper template 5 in turn, upper template 5 is provided with a stripping plate 6; lower mold includes lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Zhang jiao | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com