Automatic tensioning device for gear hobbing machine cutter bar

A technology of tensioning device and gear hobbing machine, which is applied in the direction of gear tooth manufacturing device, gear cutting machine, gear teeth, etc., can solve the problems of time-consuming and laborious tensioning and adjustment, insufficient contact rigidity of tool bar, and inability to contact tool bar at the same time, etc., to achieve special purpose Less equipment, shorter tool holder replacement time, and enhanced connection rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

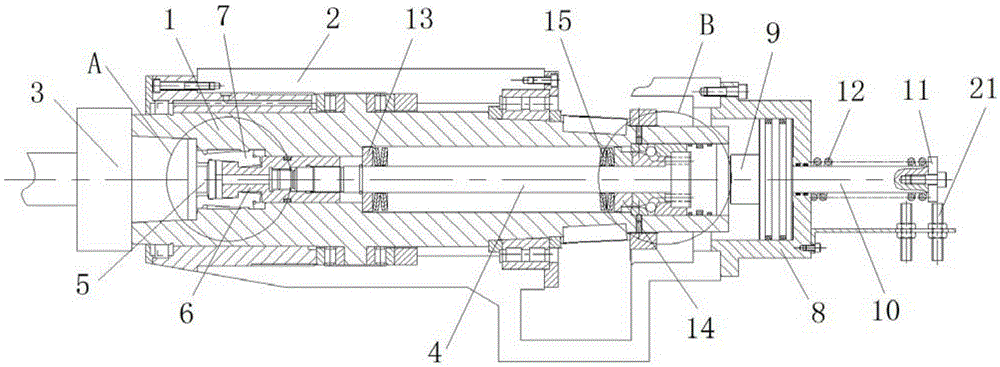

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

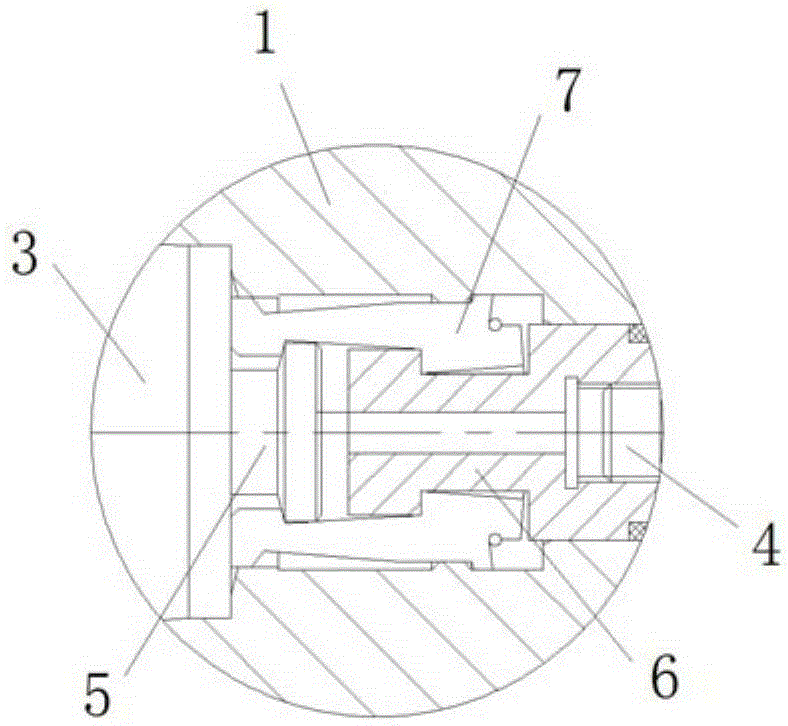

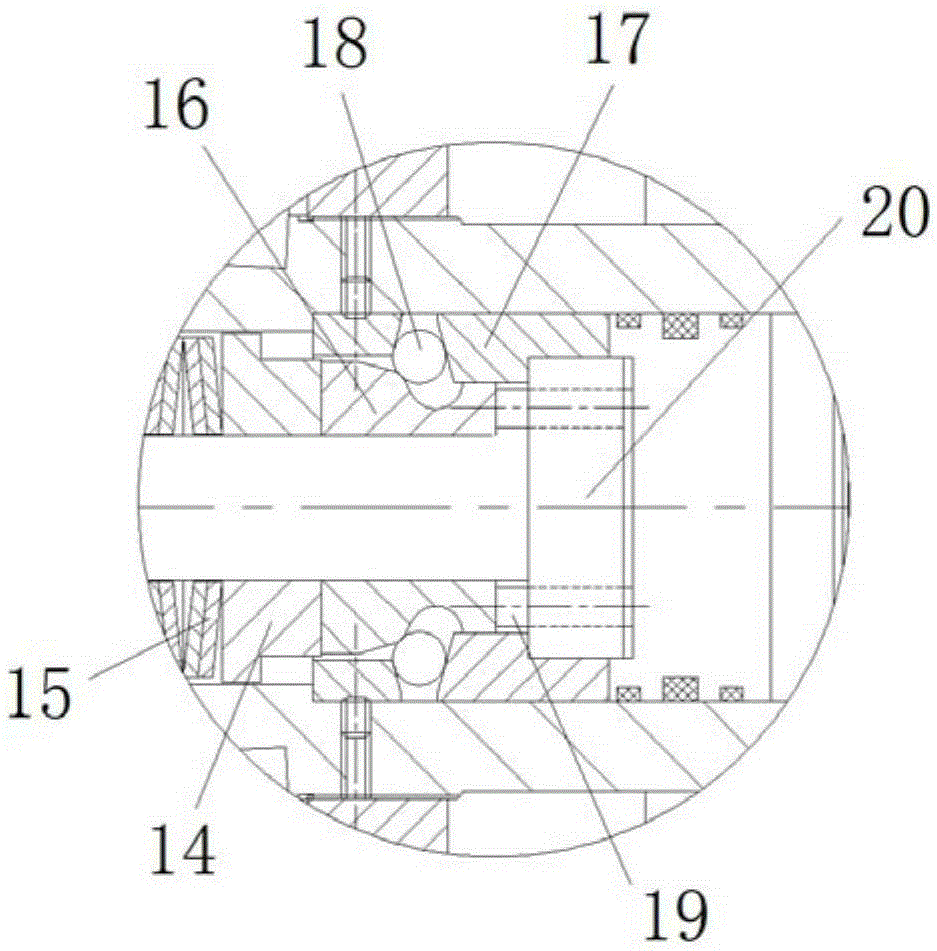

[0016] As shown in the figure, the automatic tensioning device for the tool bar of the gear hobbing machine described in this embodiment includes a main shaft 1, a tool holder housing 2 for fixing the main shaft 1, a tool bar 3 arranged at one end of the main shaft 1, and a tool bar 3 for pulling the tool bar. The pull rod 4, the pulling connector that is arranged between the knife rod 3 and the pull rod 4 and the telescopic device that provides the power source for the pull rod 4, the pulling connector includes a pull nail 5 fixed on the cutter rod 3, a pull nail fixed on the The transition pull stud 6 at one end of the pull rod 4 and the multi-lobe pull claw 7 that is set on the pull stud 5 and the transition pull stud 6 and connects the two together, the left and right positions of the pull rod 4 are controlled by the telescopic device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com