Laser tracking device

A technology of laser tracking and laser tracker, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of expensive laser tracker, high maintenance cost, and expensive welding system, and achieve disassembly operation Simple and reliable, easy to operate, and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

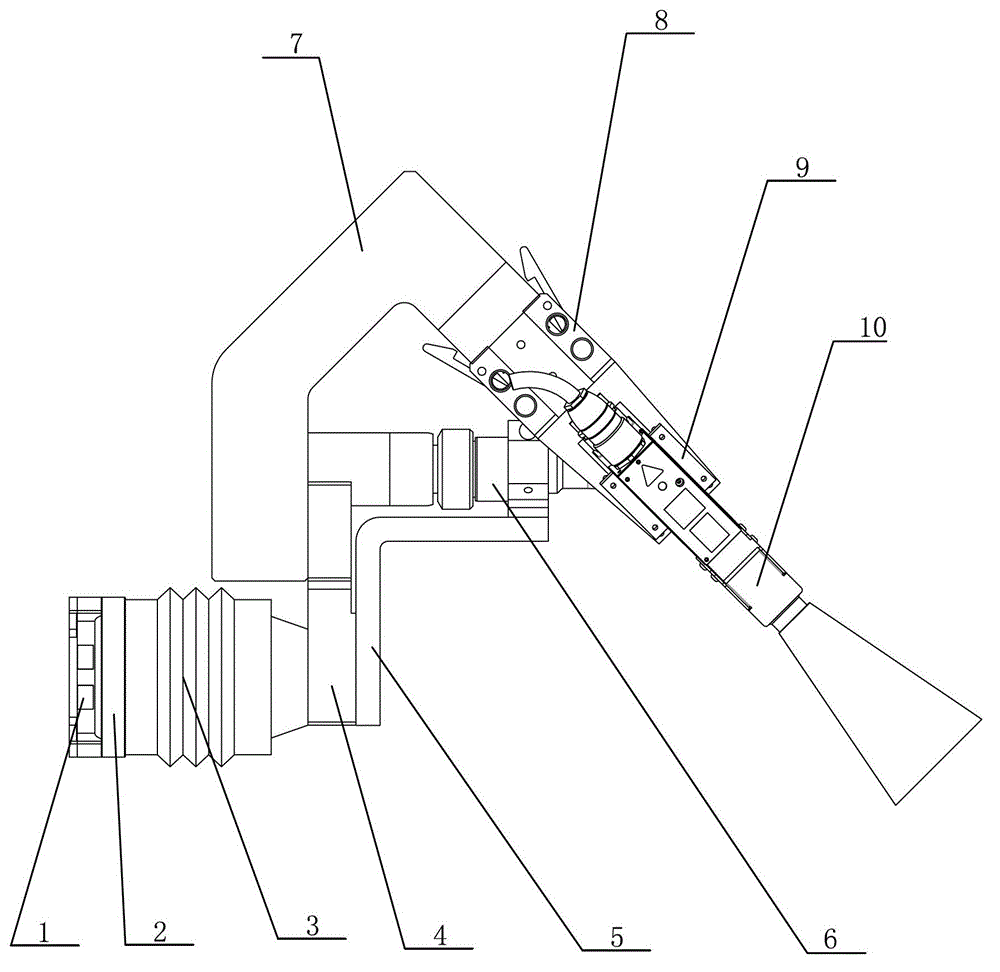

[0012] refer to figure 1 , the specific embodiment adopts the following technical solutions: it includes a welding torch assembly and a laser tracker assembly; the welding torch assembly includes a clamping gun block 1, a flange plate 2, an anti-collision sensor 3, a first panel 4, a gripper 5, and a gun neck 6 and the second panel 7; the clamp block 1 is connected to one end of the flange 2, the other end of the flange 2 is connected to the anti-collision sensor 3, and the anti-collision sensor 3 is fixedly connected to one end of the gripper 5 through the first panel 4 , the other end of the gripper 5 is connected to the gun neck 6; the first panel 4 is connected to the second panel 7; the laser tracker assembly includes a mounting base 8, a laser fixing base 9, a laser tracker 10, and the mounting base 8 is connected to the second panel 7 It is connected with the laser fixing base 9, and the laser fixing base 9 is connected with the laser tracker 10.

[0013] The welding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com