Safety brake system and motor vehicle with auxiliary safety brake system

A technology of safe braking and braking systems, applied in the direction of brakes, braking components, anti-theft vehicle accessories, etc., can solve uncivilized driving behavior, easy wear of friction plates and brake discs, and affect the safety of motor vehicles, etc. problem, achieve the effect of shortening the braking distance and facilitating the replacement of tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

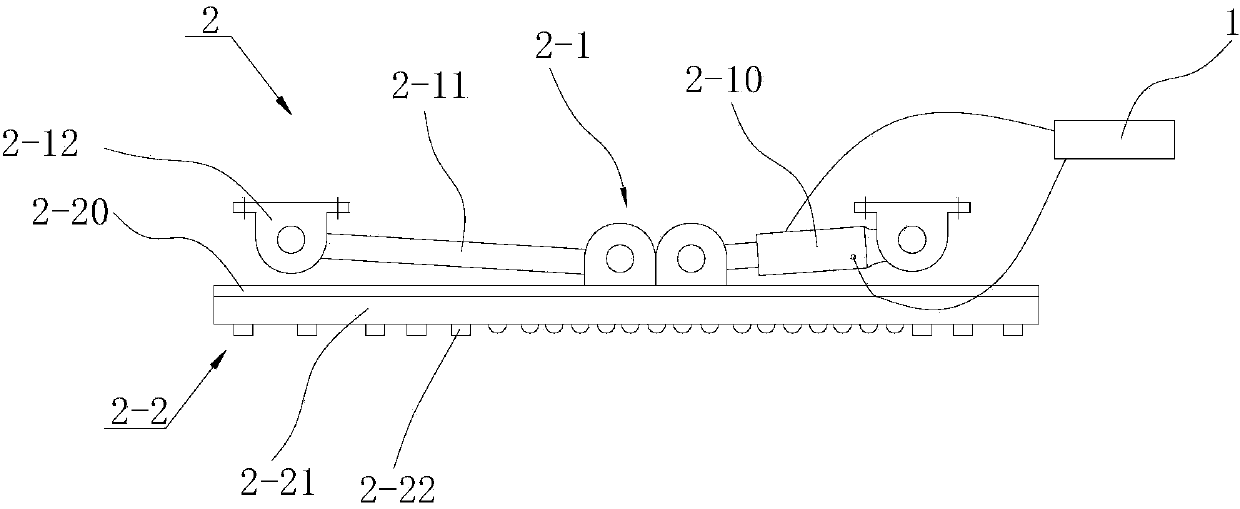

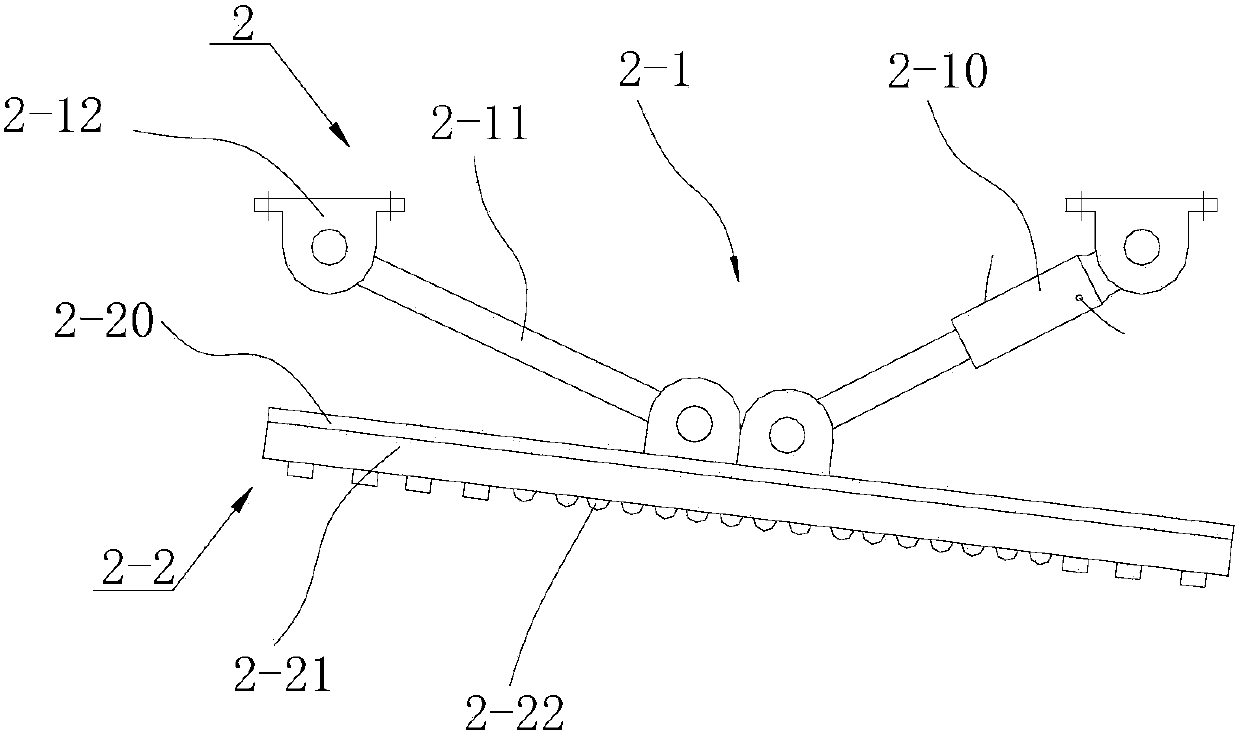

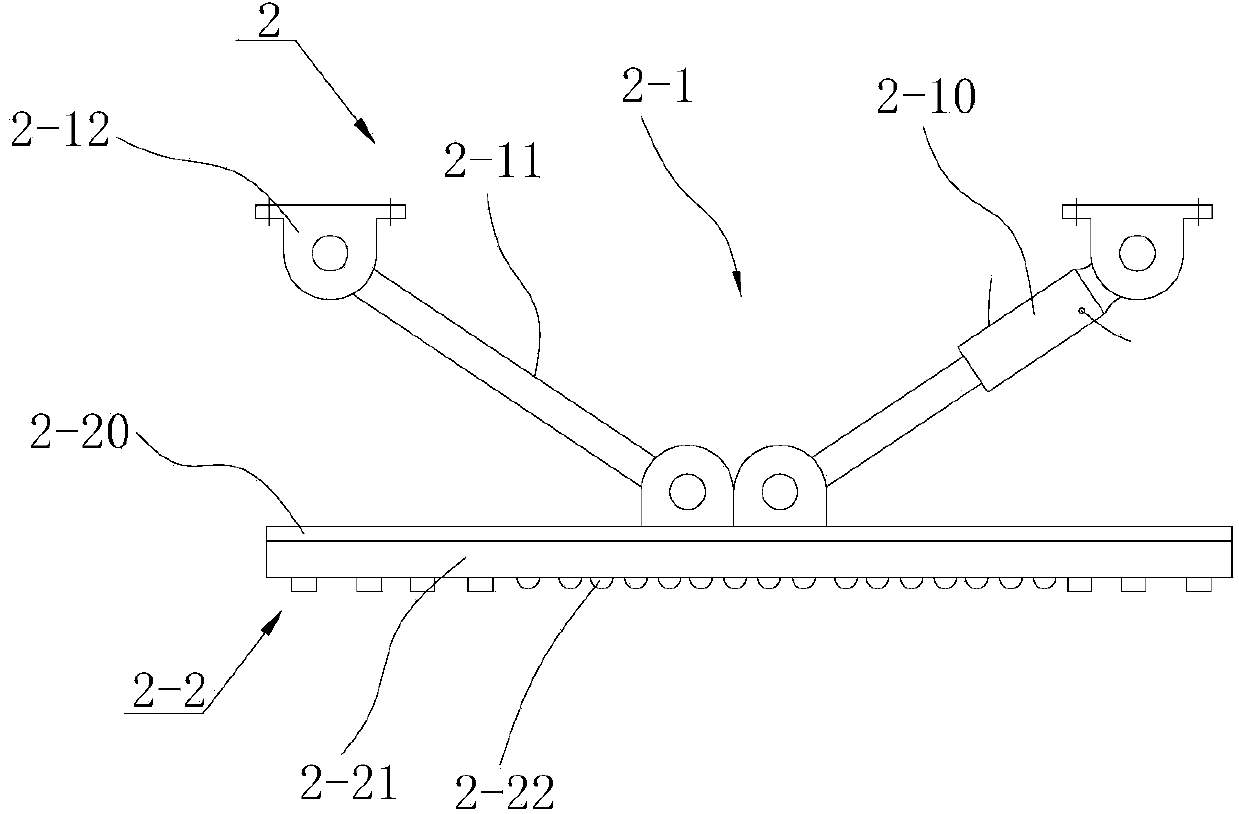

[0056] Embodiment 2: Please refer to 8; in the above structure, the friction assembly includes a mounting plate 2-201, and the mounting plate is provided with several mutually independent mounting grooves 2-202, and friction is installed in each mounting groove Block 2-203, the upper surface of the friction block is connected with a push rod 2-204, and the push rod is connected to the telescopic cylinder 2-205, and the telescopic cylinder is fixedly installed on the mounting plate 2-201. This structural design can The number of friction blocks is selected according to actual needs, and a reasonable friction coefficient has been increased.

Embodiment 3

[0057] Embodiment 3: Please refer to 9; the resistance mechanism 2 is provided with more than two groups, and the drag rod of the adjacent resistance mechanism or the first telescopic cylinder and the friction surface of the friction assembly form a triangular structure, which also utilizes the triangular structure. The stability makes it stable and supports; but the layout of trapezoidal structure or rectangular structure can also be used. The two groups of resistance mechanisms can be started synchronously, or one of them can be started first, that is, when the friction needs to be further increased, the second group of resistance mechanisms can be started, thereby expanding the scope of application of the present invention.

[0058] In order to prevent interference between two adjacent resistance mechanisms, an elastic connecting member 2-3 is connected between the friction components of the adjacent resistance mechanisms.

[0059] In order to prevent the return of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com