A preparation method of inorganic bonding material and inorganic bonding material obtained therefrom

An inorganic bonding and slurry technology, applied in conductive materials, inorganic adhesives, adhesives and other directions dispersed in non-conductive inorganic materials, which can solve the problems of high dielectric strength and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

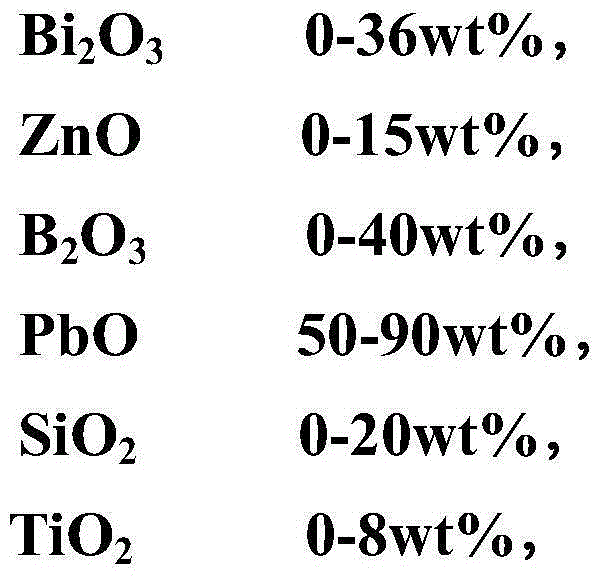

[0027] Firstly, the high-temperature melting powder is prepared as follows: the powder raw material with a purity greater than 99.99% is weighed according to the following ratio: Bi 2 o 3 1wt%, ZnO2wt%, B 2 o 3 25wt%, PbO70wt%, SiO 2 1wt%, TiO 2 1%, then ball milled in a ball mill jar for 4 hours, dried at 60°C, melted at 1350°C for 1 hour, and then water quenched.

[0028] Then, the high-temperature sintered powder was prepared as follows: La 2 o 3 Powder and Al with a purity greater than 99.99% 2 o 3 The powders were weighed according to the ratio of 20wt% and 80wt%, and mixed by ball milling for 3 hours, pressed into agglomerates under 200MP pressure, sintered at 1550°C for 5 hours, after crushing, ball milled for 30 hours, and dried at 60°C. La with a particle size of 75nm 2 o 3 / Al 2 o 3 Composite powder; SrCO with a purity greater than 99.99% 3 Powder and TiO with a purity greater than 99.99% 2 The powders were weighed at a ratio of 40wt% and 60wt%, and mix...

Embodiment 2

[0034] Firstly, the high-temperature melting powder is prepared as follows: the powder raw material with a purity greater than 99.99% is weighed according to the following ratio: Bi 2 o 3 2wt%, ZnO6wt%, B 2 o 3 1wt%, PbO75wt%, SiO 2 15wt%, TiO 2 1%,

[0035] Then ball milled in a ball mill jar for 4 hours, dried at 60°C, melted at 1350°C for 1 hour, and then water quenched.

[0036] Then, the high-temperature sintered powder was prepared as follows: La 2 o 3 Powder and Al with a purity greater than 99.99% 2 o 3 The powders were weighed according to the ratio of 30wt% and 70wt%, and mixed by ball milling for 4 hours, pressed into agglomerates under 220MP pressure, sintered at 1500°C for 8 hours, after crushing, ball milled for 24 hours, and dried at 80°C to make a medium La with a particle size of 80nm 2 o 3 / Al 2 o 3 Composite powder; SrCO with a purity greater than 99.99% 3 Powder and TiO with a purity greater than 99.99% 2 The powder is weighed according to th...

Embodiment 3

[0041] First prepare the high-temperature melting powder by the following method: the powder with a purity greater than 99.99% is weighed according to the following ratio: Bi 2 o 3 31wt%, ZnO12wt%, B 2 o 3 1wt%, PbO50wt%, SiO 2 0wt%, TiO 2 6%, then ball milled in a ball mill jar for 2 hours, dried at 70°C, melted at 1250°C for 1 hour, and then water quenched.

[0042] Then, the high-temperature sintered powder was prepared as follows: La 2 o 3 Powder raw materials and Al with a purity greater than 99.99% 2 o 3 The powder is weighed according to the proportion of each 50wt%, mixed by ball milling for 3 hours, pressed into agglomerates under 220MP pressure, sintered at 1600°C for 5 hours, after crushing, ball milled for 40 hours, and dried at 60°C to make a median particle size of 70nm La 2 o 3 / Al 2 o 3 Composite powder; SrCO with a purity greater than 99.99% 3 Powder and TiO with a purity greater than 99.99% 2 The powders were weighed at a ratio of 55wt% and 45wt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com