Method for producing coal-based natural gas through crushed coal pressurized gasification combined with water-coal slurry gasification

A technology of pressurized gasification of crushed coal and coal-to-natural gas, applied in the gasification of granular/powdered fuel, gas fuel, petroleum industry, etc., can solve the problems of high-concentration phenol-containing process wastewater, and achieve the goal of reducing the cost of sewage treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

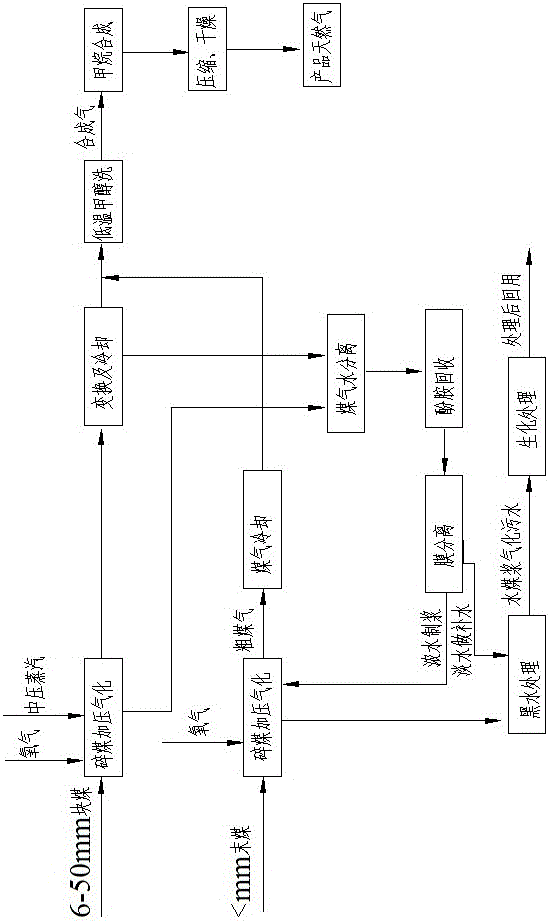

[0034] Such as figure 1 As shown, the method for producing coal-to-natural gas by pressurized gasification of crushed coal combined with coal-water slurry gasification according to the present invention, the specific process steps are as follows:

[0035] 1. After the raw coal is crushed and screened, it is divided into 6~50mm lump coal and <6mm fine coal, which are sent to the crushed coal pressurized gasification device, coal-water slurry gasification device and boiler respectively by the belt conveyor.

[0036] 2. 6~50mm lump coal is gasified in the crushed coal pressurized gasifier, the gasification agent is medium pressure steam and oxygen, and the volume ratio of medium pressure steam and oxygen is 6~8:1. The 180°C, 3.8MPa crude gas leaving the gasifier is converted into CO, H 2 、CH 4 、H 2 O and CO 2 as the main component, and CnHm, N 2 , sulfide, tar, naphtha, phenols and ammonia and other impurities.

[0037] 3. The crushed coal is pressurized and gasified and th...

Embodiment 2

[0051] As shown in the figure, the method for producing coal-to-natural gas by pressurized gasification of crushed coal combined with coal-water slurry gasification according to the present invention, the specific process steps are as follows:

[0052] 1. After the raw coal is crushed and screened, it is divided into 6~50mm lump coal and <6mm fine coal, which are sent to the crushed coal pressurized gasification device, coal-water slurry gasification device and boiler respectively by the belt conveyor.

[0053] 2. 6~50mm lump coal is gasified in a crushed coal pressurized gasifier, the gasification agent is medium pressure steam and oxygen, and the volume ratio of medium pressure steam and oxygen is 6:1. The 180°C, 3.8MPa crude gas leaving the gasifier is converted into CO, H 2 、CH 4 、H 2 O and CO 2 as the main component, and CnHm, N 2 , sulfide, tar, naphtha, phenols and ammonia and other impurities.

[0054] 3. The crushed coal is pressurized and gasified, and the crude...

Embodiment 3

[0068] Such as figure 1 As shown, the method for producing coal-to-natural gas by pressurized gasification of crushed coal combined with coal-water slurry gasification according to the present invention, the specific process steps are as follows:

[0069] 1. After the raw coal is crushed and screened, it is divided into 6~50mm lump coal and <6mm fine coal, which are sent to the crushed coal pressurized gasification device, coal-water slurry gasification device and boiler respectively by the belt conveyor.

[0070] 2. 6~50mm lump coal is gasified in a crushed coal pressurized gasifier, the gasification agent is medium pressure steam and oxygen, and the volume ratio of medium pressure steam and oxygen is 7:1. The 180°C, 3.8MPa crude gas leaving the gasifier is converted into CO, H 2 、CH 4 、H 2 O and CO 2 as the main component, and CnHm, N 2 , sulfide, tar, naphtha, phenols and ammonia and other impurities.

[0071] 3. The crushed coal is pressurized and gasified and the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com