High-power radial plunger pump

A radial column, high-power technology, applied in the mechanical field, can solve the problems of increasing radial size, large radial size space, large friction loss, etc., and achieves reduction of radial size, radial size reduction, and equipment weight. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

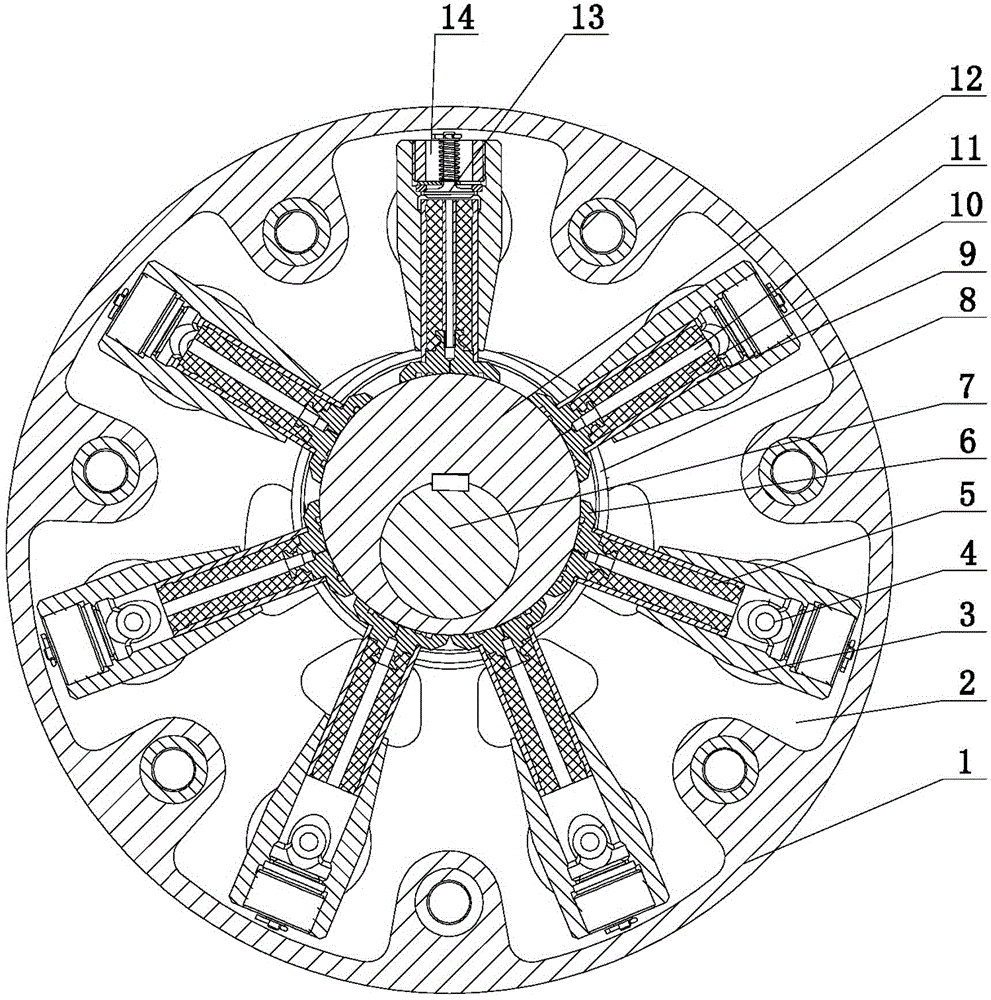

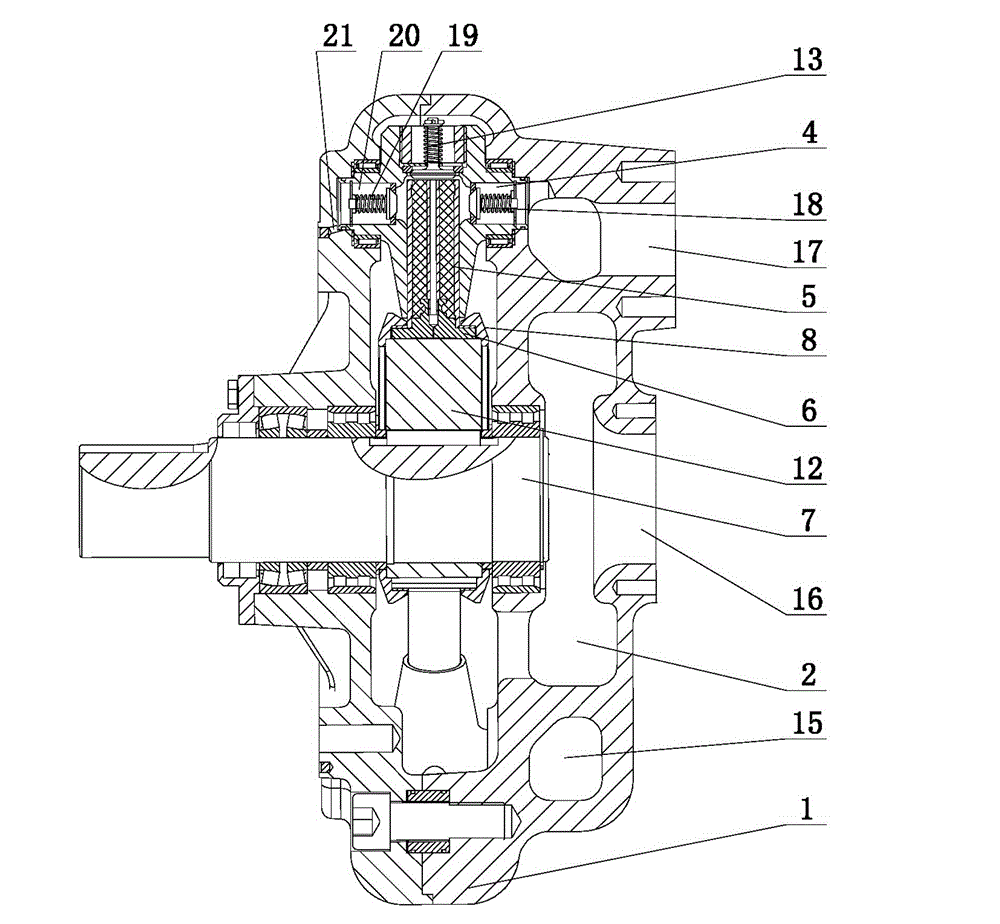

[0019] The present invention includes a housing 1 with a cavity 2 inside. The surface of the housing 1 is provided with a liquid suction port 16 communicating with the cavity 2, and the middle of the housing 1 is provided with a cam 12 through a rotating shaft 7, and the cam 12 is provided with a pull ring 8. At least two plungers 5; the end of each plunger 5 is arranged in a plunger cylinder 3, the end of the plunger cylinder 3 is provided with a liquid inlet 14 communicating with the cavity 2, and the liquid inlet 14 is provided There is a suction valve 13; both sides of the plunger cylinder 3 are provided with a first hollow trunnion 4 and a second hollow trunnion 20 that cooperate with the housing 1; an annular high-pressure chamber 15 is provided in the housing 1; The first hollow trunnion 4 of each plunger cylinder 3 is in communication with the annular high-pressure chamber 15. The first hollow trunnion 4 is provided with a drain valve 18 corresponding to the annular high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com