Harmonic drive gear mesh and flexible gear deformation dynamic characteristic testing system

A technology of dynamic characteristics and harmonic transmission, applied in the field of harmonic transmission, can solve problems such as low work efficiency, large measurement error, and complicated operation, and achieve the effect of simple structure, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

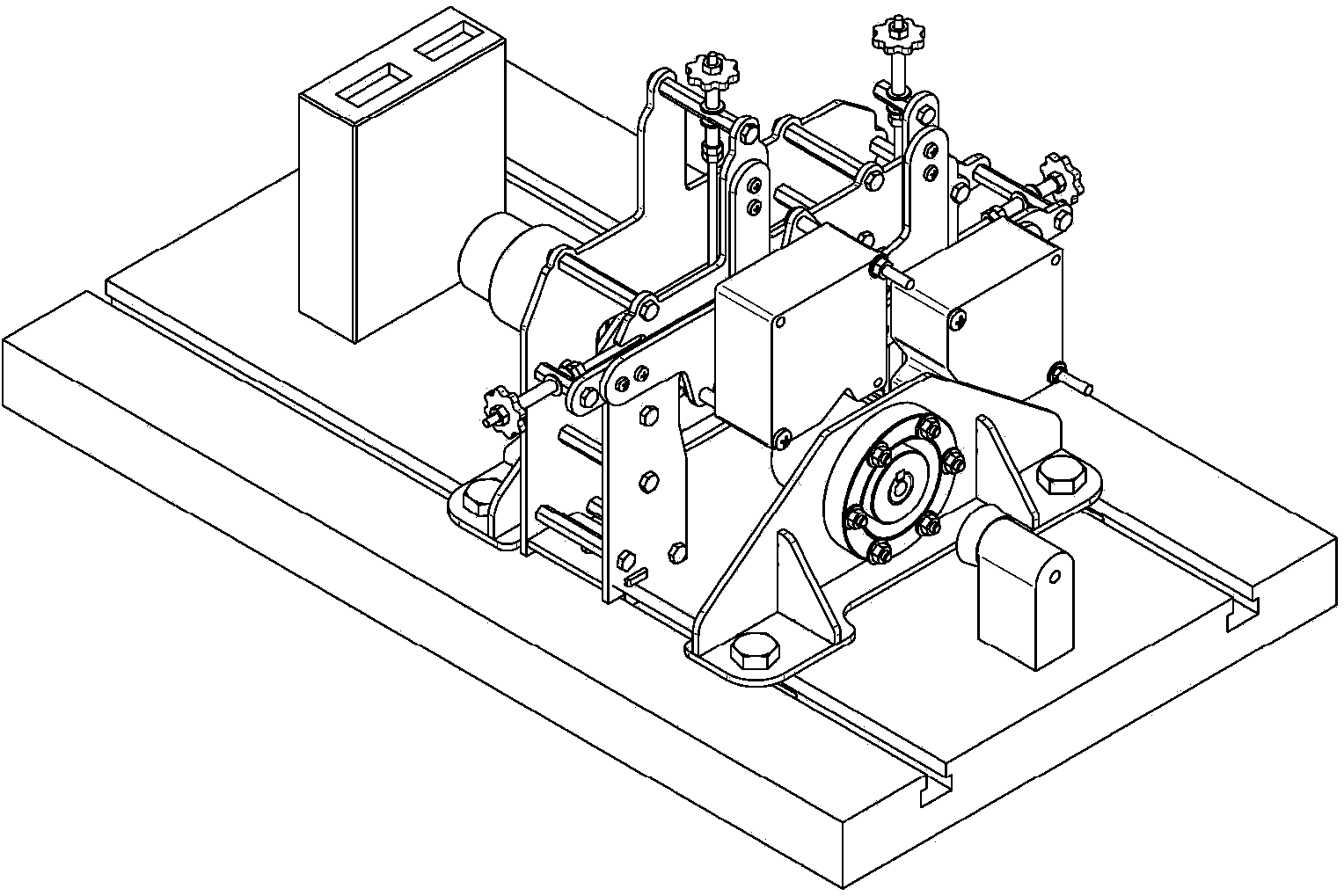

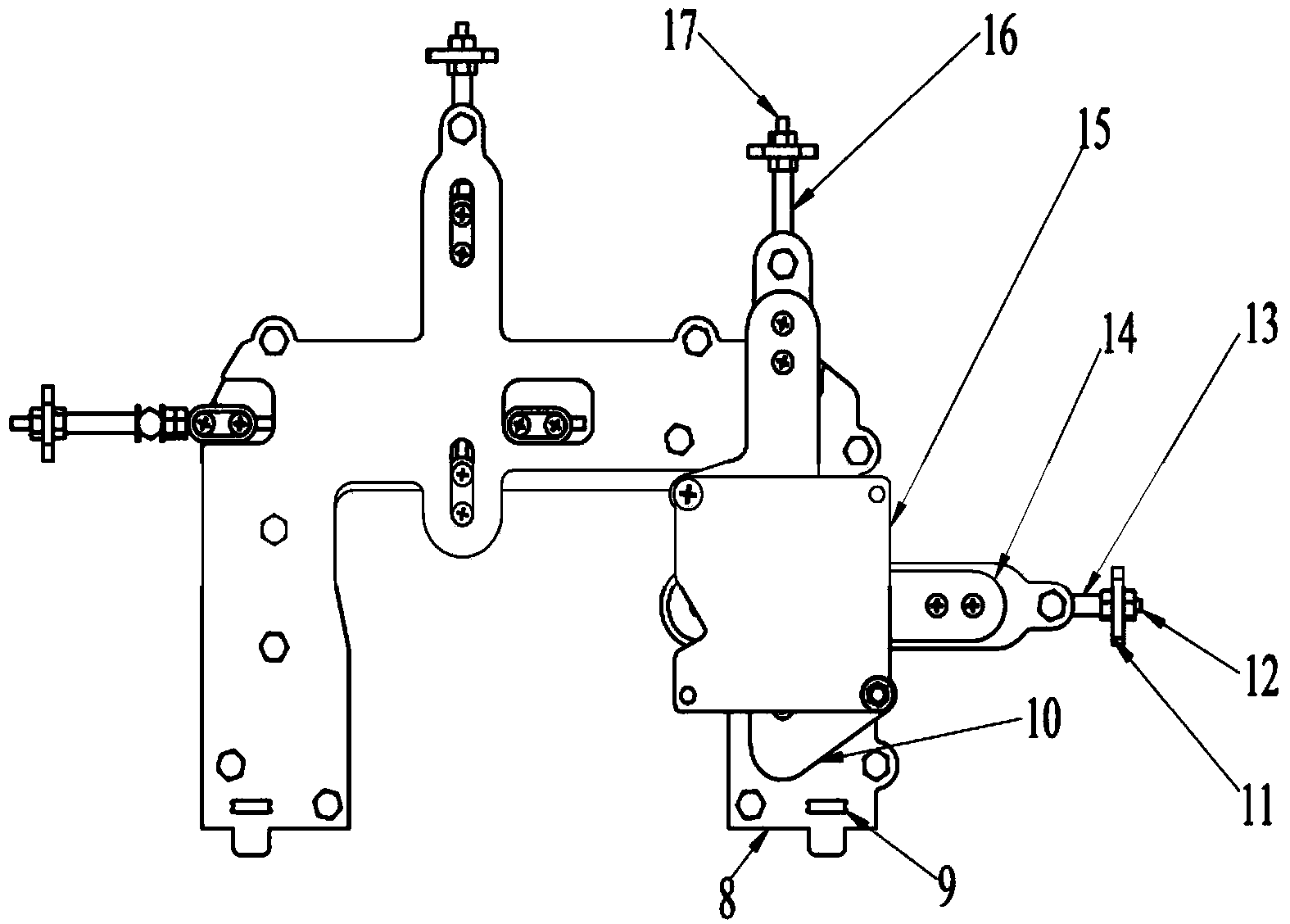

[0038] The present invention provides a testing system for the dynamic characteristics of harmonic drive gear tooth meshing and flexspline deformation. The structure and working principles of the present invention will be further explained below with reference to the accompanying drawings.

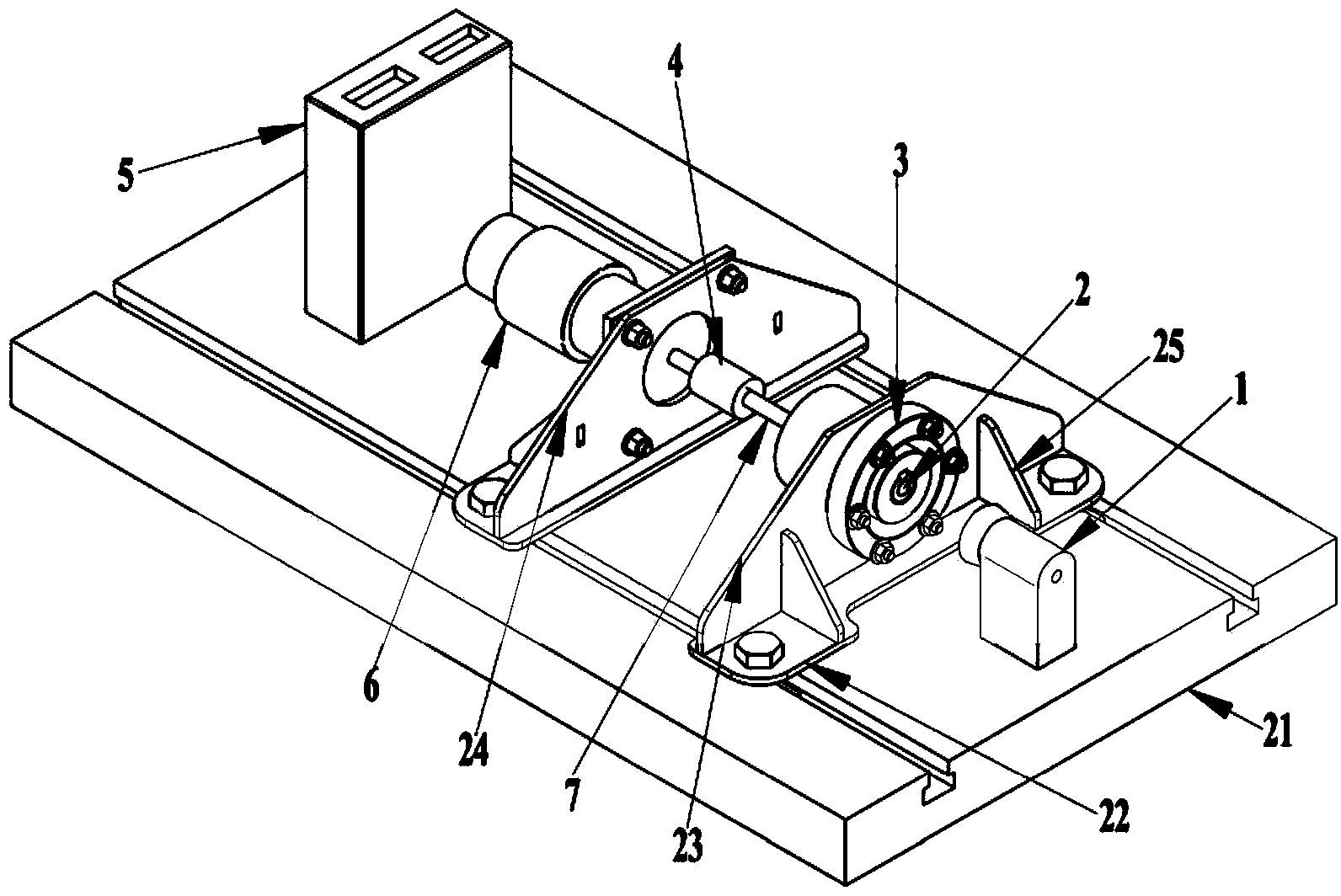

[0039] Such as figure 1 As shown, the system mainly includes a base, a harmonic bracket, a motor bracket, a sliding frame, and two sets of laser displacement sensor translation systems.

[0040] Such as figure 2 As shown, the main body of the base is the base 21, and two parallel T-shaped grooves are provided on the base 21. The harmonic bracket is composed of a first bracket 22, a second bracket 23, and a fourth bracket 25, which are matched with the T-slot on the base 21 through a T-shaped slider, and the harmonic reducer 3 is fixed on the harmonic bracket; motor bracket It is composed of a first bracket 21, a third bracket 24, and a fourth bracket 25. The T-shaped slider is matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com