Solar multifunctional translation sprinkler irrigation machine

A multi-functional, translational technology, applied in the direction of renewable energy machines, agricultural machinery and equipment, climate change adaptation, etc., can solve the problems of inability to move, inconvenient repair of production equipment, poor promotion, etc., to achieve low production and installation costs, The effect of reducing the workload of farmers and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

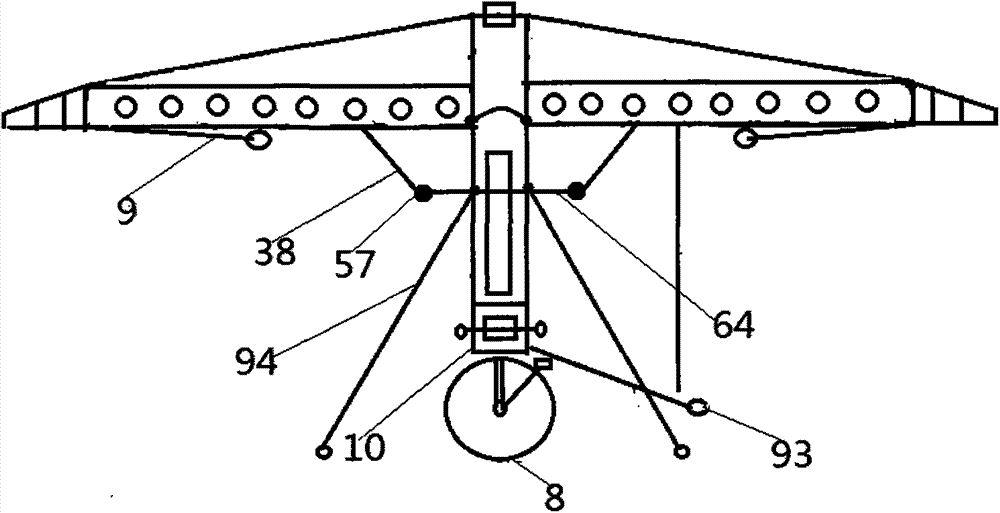

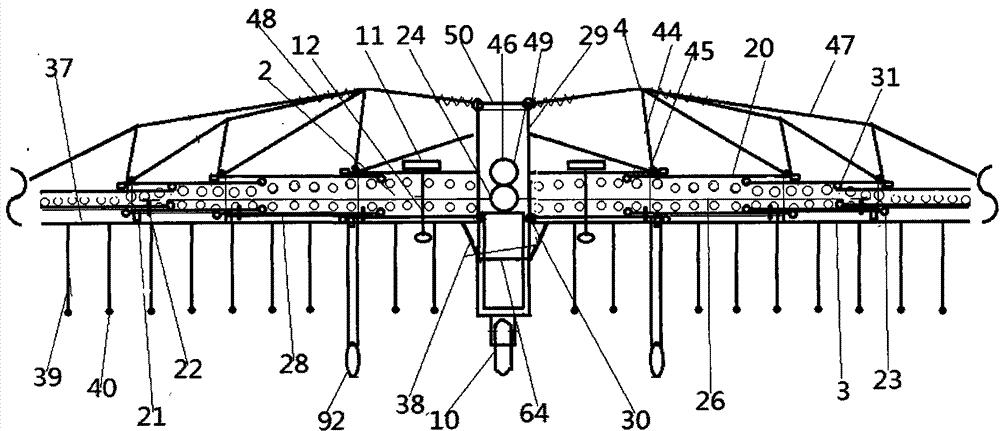

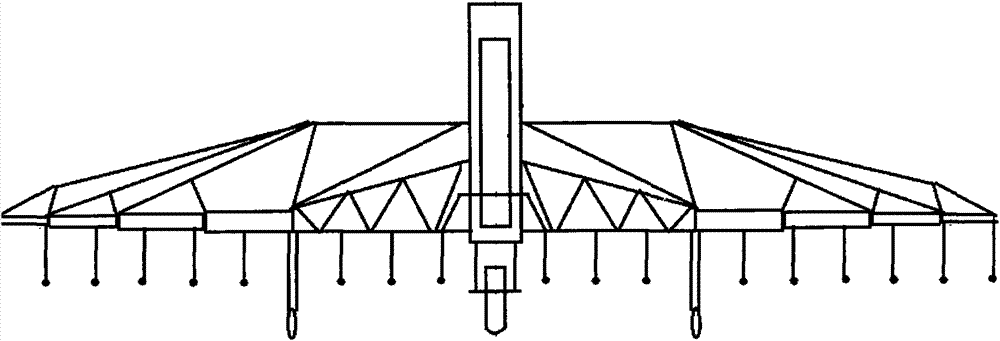

[0043] The invention improves the telescopic beam and the like into an electric telescopic type, a cable telescopic type or a splicing type on the basis of the existing sprinkler irrigation machine, so that the operation is convenient, simple and fast. At the same time, the power system is equipped with solar power, mainly solar power, supplemented by gasoline and diesel power, so as to reduce energy consumption. The improvement of the ejector device, each telescopic beam telescopic beam is jacked up by the swingable ejector bar of its front telescopic beam, and the left and right flat cables are installed, which reduces the overall height of the sprinkler and increases the strength of the sprinkler. Increase the overall firmness of the sprinkler. A guide is installed on the front end of the driving wheel to effectively ensure that the sprinkler irrigation works according to the required route and does not crush the crops. The increased spraying system makes the sprinkler fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com