Oral liquid bottle

An oral liquid and bottle body technology, applied in the field of oral liquid bottles, can solve the problems of poor sealing at the tear opening, cannot be used for one-time use, and is not easy to tear at the tear opening, achieves good sealing and barrier function, and is conducive to large-scale The effect of production, simple and practical cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

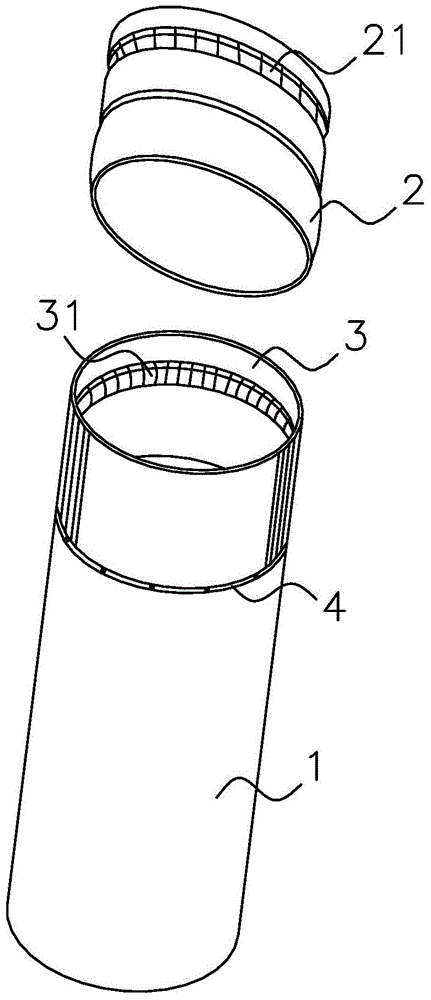

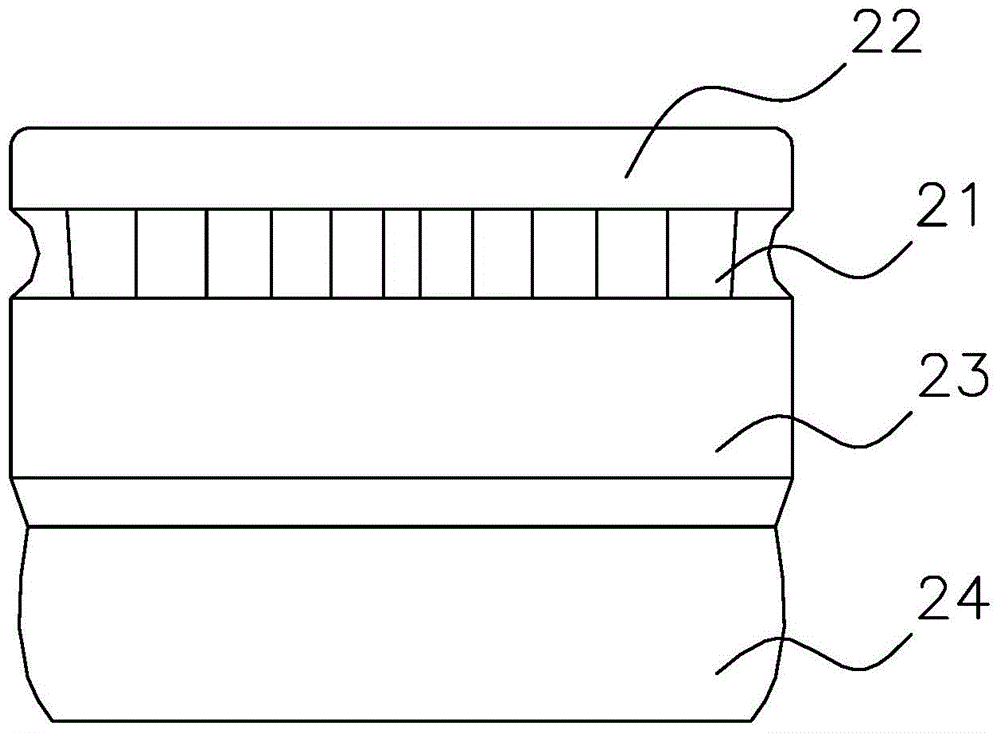

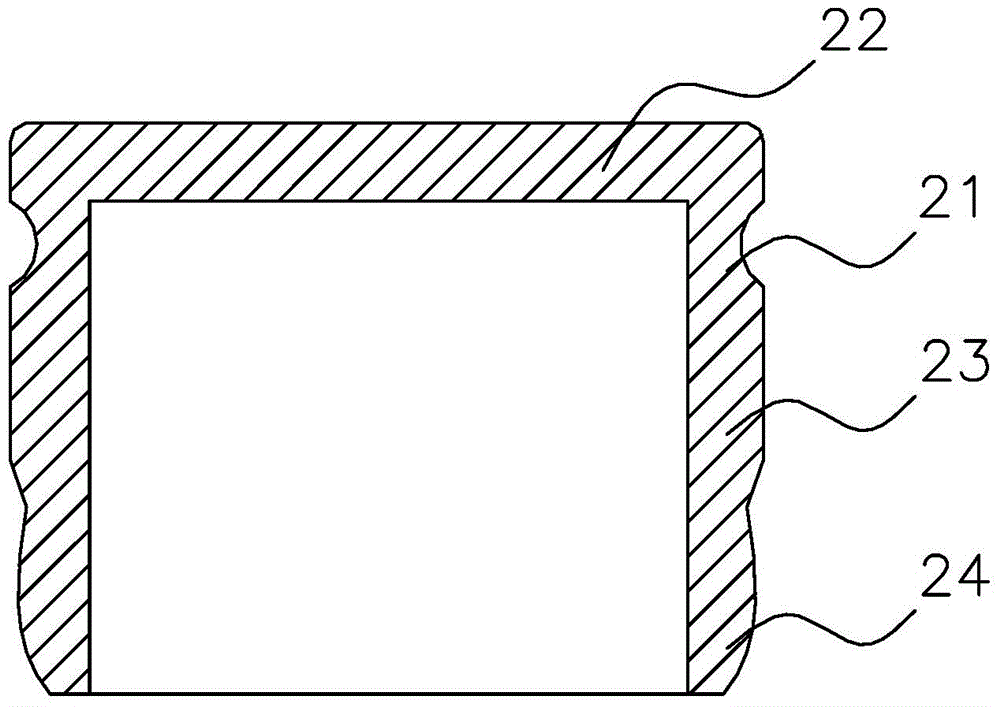

[0033] refer to figure 1 As shown, a kind of oral liquid bottle has a bottle body 1, and the upper end of the bottle body 1 is provided with a rotary cap 3, and the connection between the bottle body 1 and the rotary cap 3 is provided with a connecting rib 4 that can be twisted off, and the bottle body 1 and the rotary cap 3 are connected by connecting ribs 4, and a bottle stopper 2 is arranged in the rotating cap 3. When the rotary cap 3 is rotated to a certain degree, the connecting rib 4 is twisted off, and the rotary cap 3 is separated from the bottle body 1, and the oral liquid bottle is opened.

[0034] The outer surface of the rotary cover 3 is vertically provided with several bottle-opening ribs, which are used to increase friction and prevent slipping. The bottle-opening ribs are arranged on part or all of the outer surface of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com