Front and back blasting treatment process for clean inner wall of long pipeline

A treatment process and anti-blasting technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, pipe components, etc., can solve the problems of prolonged cleaning time of pipelines, debris left in the pipeline, poor cleaning effect, etc., and is easy to master , The time of purging is shortened, and the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

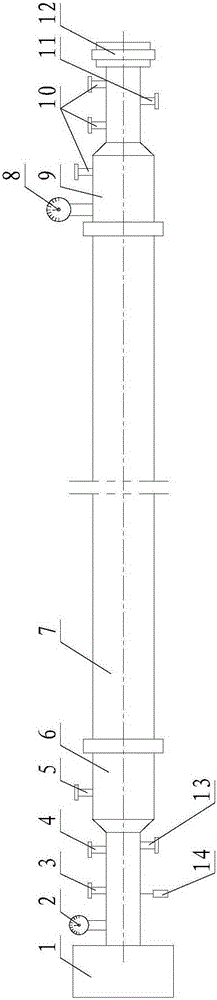

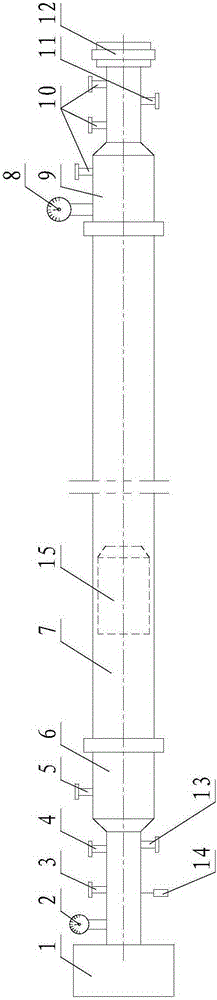

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0021] A front and back blasting treatment process for cleaning the inner wall of a long pipeline, comprising the following steps:

[0022] ⑴. First, clean the pipeline by positive blasting: the ball collection device at the end of the pipeline 7 uses a baffle 12 that has a certain bearing capacity and can be damaged when it reaches a certain pressure. Design options for devices, piping, etc. The launch end of the pipeline inlet is connected to the air compressor, and the air compressor 1 is used to start injecting air from the launch end of the pipeline entrance until the fixed kraft paper block at the end of the pipeline cannot bear the pressure and is damaged and burst. At the moment of burst, the vibration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com