High temperature thermoforming circulating water-cooled solid self-lubricating cone

A solid self-lubricating, circulating water-cooling technology, applied in the field of machinery, can solve problems such as locking, non-lubricating cones, normal temperature diameter expansion process cannot meet the requirements of high-strength and high-precision steel pipe high-precision diameter expansion, etc., to achieve simplified structure and saving Effect of saving installation and running costs and design time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

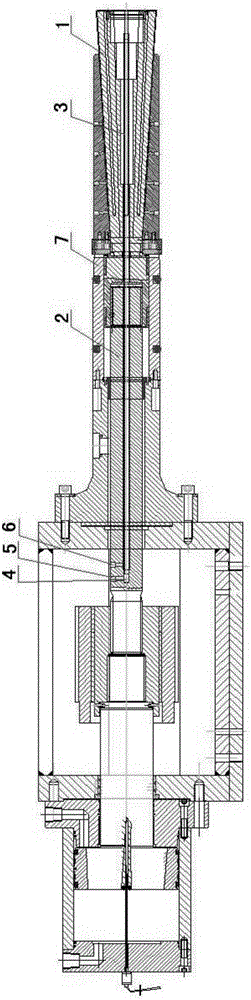

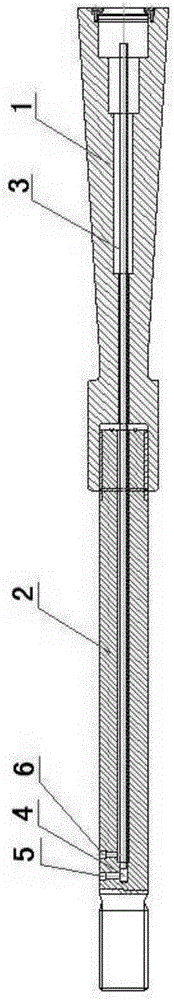

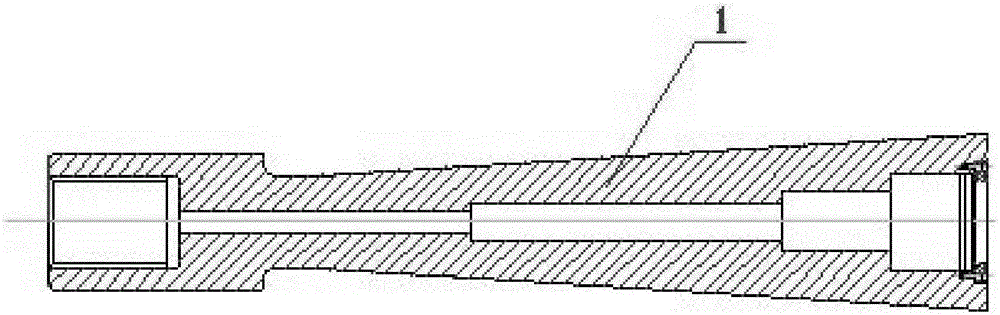

[0019] see figure 1 , The high-temperature heat-shaping circulating water-cooled solid self-lubricating cone of this embodiment is applied to a diameter expanding machine, and it includes a pyramid-shaped cone body 1 and a connecting rod 2, wherein 7 is a guide ring. It can be seen from the figure that the tail end of the pyramid-shaped cone body 1 is connected with the front end of the connecting rod 2 by threading and sealing ring.

[0020] see Figure 2 to Figure 5 , a cold water pipe 3 is installed through the installation hole at the axis of the pyramid-shaped cone body 1 and the connecting rod 2, and the tail end (left end) of the cold water pipe 3 is in the tail end (left end) of the connecting rod 2, and is connected with the connecting rod 2 The water inlet hole 4 in the tail end is sealed and communicated, the water inlet hole 4 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com