Numerical modeling method for magnesium alloy dendritic structure

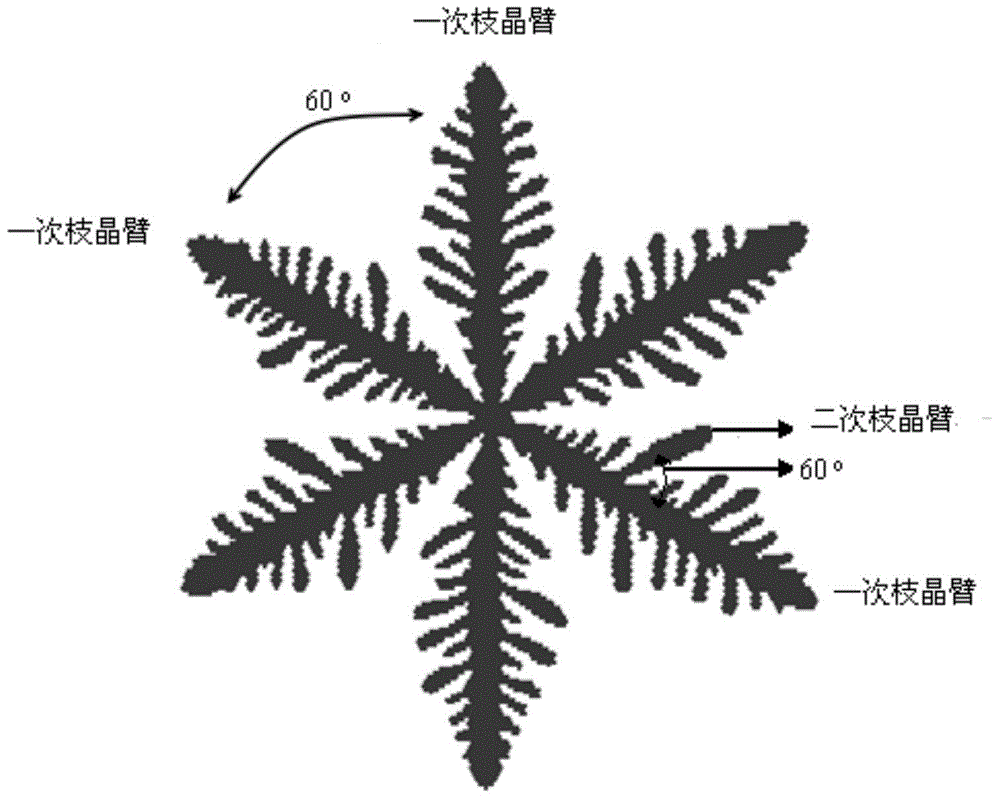

A dendrite structure and numerical simulation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the growth kinetic model of the close-packed hexagonal dendrite tip is unclear and cannot accurately predict magnesium alloy dendrites. Crystal growth and other problems, to achieve the effect of long equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

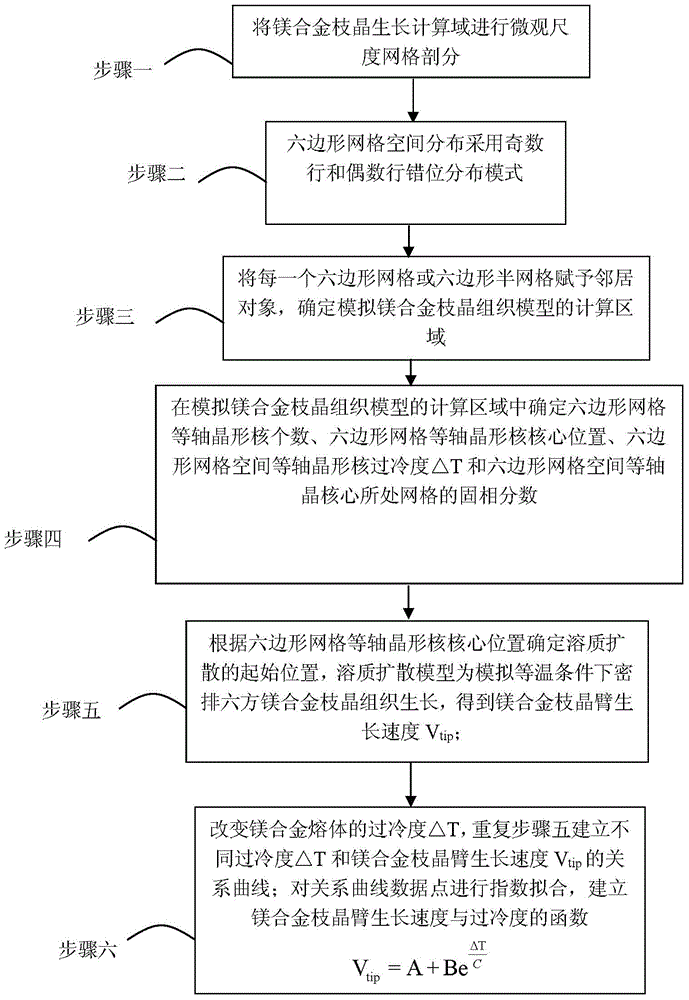

[0025] Specific Embodiment 1: A method for numerical simulation of a magnesium alloy dendrite structure in this embodiment is specifically carried out in accordance with the following steps:

[0026] Step 1. Subdividing the magnesium alloy dendrite growth calculation domain into a micro-scale grid, wherein the micro-scale grid adopts a hexagonal grid with a side length of L;

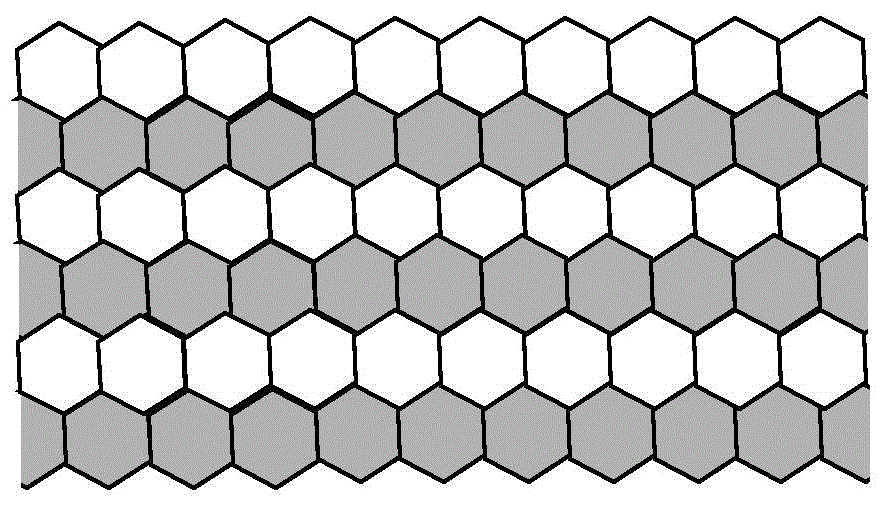

[0027] Step 2. The hexagonal grid distribution adopts the odd-numbered row and even-numbered row dislocation distribution mode as follows: figure 2 , the first grid in the even-numbered row is a half grid (the right half grid of the hexagonal grid), and the last grid is a half grid (the left half grid of the hexagonal grid);

[0028] Step 3, assign each hexagonal grid or hexagonal semi-grid to the neighbor object, and determine the calculation area for simulating the magnesium alloy dendrite structure model;

[0029] Step 4. Determine the number of equiaxed crystal nuclei in the hexagonal grid, the pos...

specific Embodiment approach 2

[0036]Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the magnesium alloy dendrite growth calculation domain is divided into micro-scale grids:

[0037] (1) A hexagonal grid with a side length of L is adopted, and a main diagonal of the hexagonal grid coincides with the Y axis in the X-Y Cartesian coordinate system;

[0038] (2) The angles between the other two main diagonals and the X axis are 30° and -30°; the number of hexagonal grids in the X axis direction is an integer n>100, and the hexagonal grids in the Y axis direction The number of grids is an integer m>100, and m is an even number; among them, the two main diagonals place the hexagon with two sides parallel to the Y axis, and one main diagonal is: located in the first limit One vertex of the hexagon, the connection line between the third vertex in the clockwise direction with the vertex; the other main diagonal is: a vertex of the hexagon located in the fourth term, and the ...

specific Embodiment approach 3

[0041] Specific embodiment three: this embodiment is different from specific embodiment one or two: in step 3, each hexagonal grid or hexagonal half grid is given to the neighbor object as:

[0042] (1) In the calculation area of the simulated magnesium alloy dendrite structure model, determine the mark as j o = 1,k o There are 6 adjacent hexagonal grids around the hexagonal grid with =1, and their marks are: N 1-left (j=n,k=k o ), N 2-right (j=j o +1,k=k o ), N 3-upleft (j=j o , k=m), N 4-upright (j=j o +1, k=m), N 5-downleft (j=j o ,k=k o +1) and N 6-downright (j=j o +1,k=k o +1);

[0043] (2), in the calculation area of the simulated magnesium alloy dendrite structure model, determine the mark as j o = n,k o There are 6 adjacent hexagonal grids around the hexagonal grid with =1, and their marks are: N 1-left (j=j o -1,k=k o ), N 2-right (j=1,k=k o ), N 3-upleft (j=j o , k=m), N 4-upright (j=1, k=m), N 5-downleft (j=j o ,k=k o +1) and N 6-dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com