A wool vegetable impurity removal device

An impurity removal, plant-based technology, applied in fiber processing, mechanical processing, textiles and papermaking, etc., can solve the problems of destroying the ecological environment, polluting the environment, destroying the original quality of wool fibers, and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

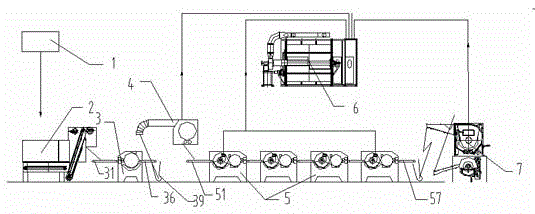

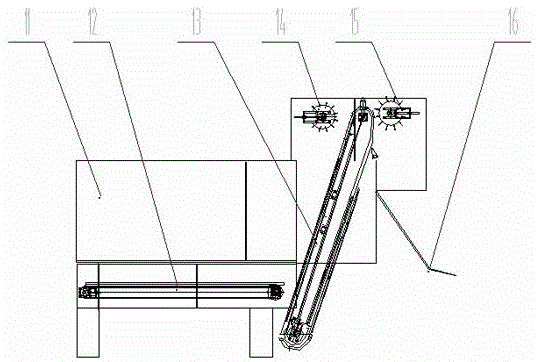

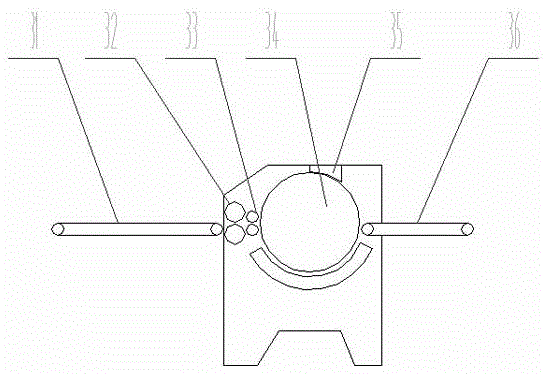

[0018] Such as figure 1 As shown, a wool vegetable impurity removal device includes a wool humidifier 1 for humidifying wool, a wool feeding machine for preliminary opening treatment of the humidified wool, further opening and preliminary opening of the vegetable impurities contained in wool. Card roller opener for cleaning impurities 3. Single licker-in roller cleaning opener for intermediate cleaning of vegetable impurities contained in wool 5. Wool cleaning for fine and impurity removal of vegetable impurities contained in wool Machine 7 and the dedusting device 6 for cleaning and opening the single licker-in machine 5 and wool cleaning machine 7 and conveying the impurities contained in the wool air flow; the outlet of the wool humidifier 1 is arranged on the wool feeding machine Above the feed port of 2, the discharge port of the wool feeder 2 is connected with the second conveying flat curtain 31 arranged on the feed port of the comb roller opener 3 through the drip plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com