Method for replacing building shock insulation rubber support

A shock-absorbing rubber and replacement method technology, which is applied in the direction of construction, building components, and building maintenance, can solve the problems of replacing bearings, large local stress, and heavy weight, and achieve uniformity of force, low construction costs, and high construction efficiency. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

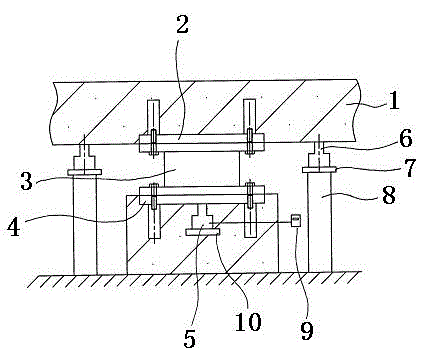

[0031] The structure of the replacement method for building shock-isolation rubber bearings proposed by the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] like figure 1 As shown, it is a structural schematic diagram of the joint between the upper building body and the building isolation rubber bearing during the replacement process, including the upper building body 1, and the upper embedded board 2 is arranged under the upper building body 1, and the upper embedded board 2 The bottom is the building isolation rubber bearing 3, the building isolation rubber bearing 3 is the lower embedded plate 4, and the lower embedded plate 4 is the force-measuring jack 5, and the building isolation rubber bearing 3 is provided with a jack 6 and a temporary support 8 for the load cell 7 .

[0033] A backing plate 10 is arranged between the bottom of the force-measuring jack 5 and the pier top, which improves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com